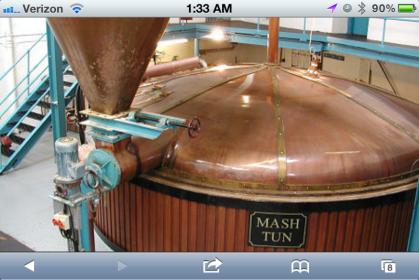

The mash tun shown is like a double boiler with 2 jackets, one on the lower area where smaller batches would set, and what looks like the rest of the tank side for the upper jacket. They are using 60 PSI steam for the higher temperatures needed to get temperature rise, and expect continuous stirring to keep mash suspended and circulating against heated surfaces. For the homebrewer this is an ambitious project that is beyond the skills and resources of most, and beyond the capabilities of the current brewtroller and BCS control platforms to control.

Direct steam injected mash systems have been around 17+ years and have a number of negative aspects with steam generation, delivery, and control, which is why so few are ever seen. There are a few threads from the past documenting the builds, but no follow on after they have been in operation for a while to document the long term use in brewing. Main problems were the lack of steam generating capacity, the dispersion of the steam into the mash quietly, and knowing when to stop the steam to hit step temperature.

The direct fire RIMS, Electric RIMS and HERMS systems are in vogue currently as they are constructable by most of the technically adept folks and are low risk methods that give reasonable results.

The other steam heating method of injecting steam into the circulating wort for step mashing requires more steam than electric or pressure cookers can supply, and requires a steam generation source with 10 KW+ capability with superheating.