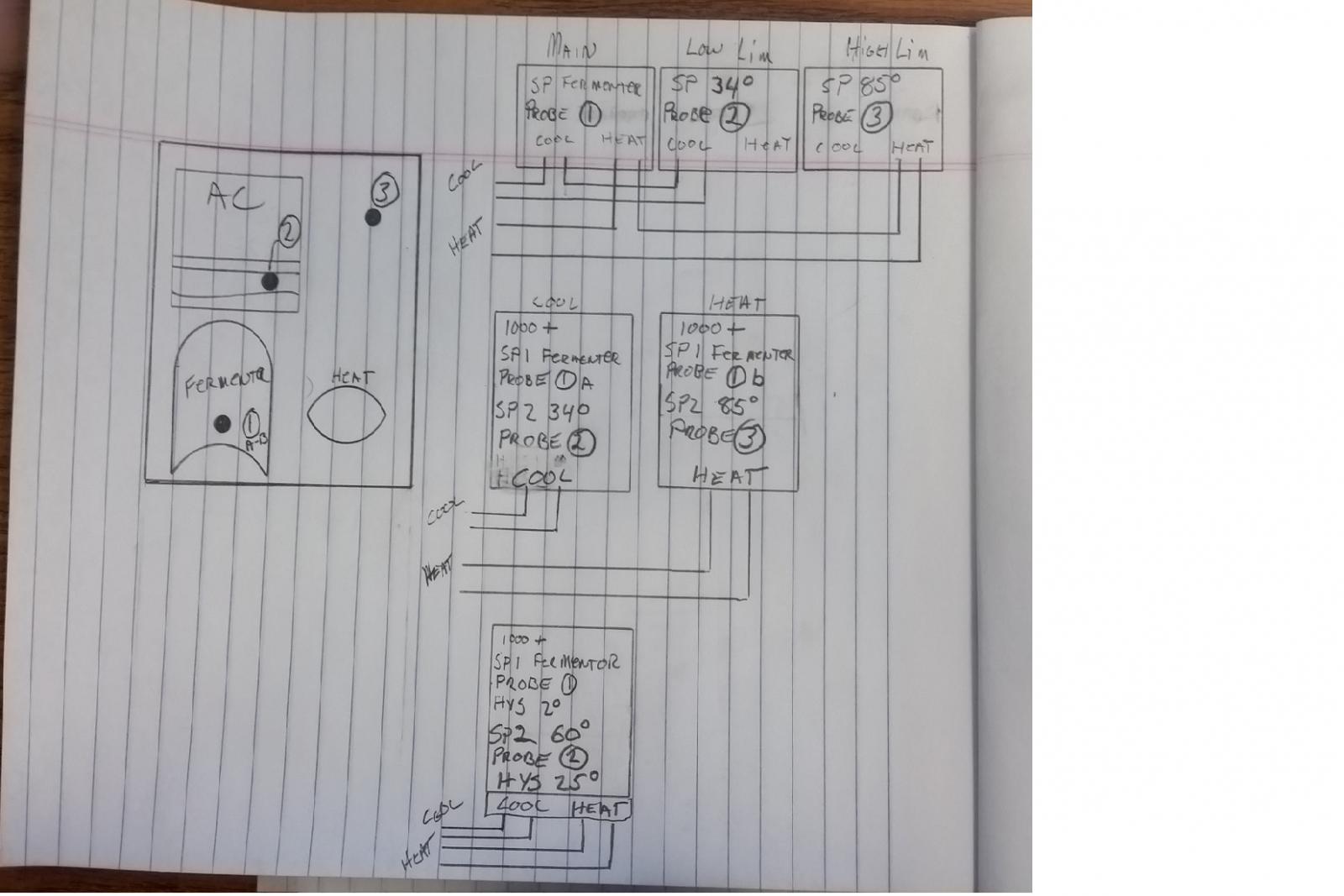

Firstly, yes the hysteresis limits

could be changed. But, it would still be dependent on on setpoint, so you'd be limited to only 60'ish in this case.

I do think that the easy solution would be to use an extra STC-1000 for the AC to stop it from frosting up.

Look into getting a lower power heater. You do not need to raise temps quickly. In an enclosed space, a little heat goes a long way.

Also, what @stpug said, make sure the AC draws less than 15 amps.

You are free to play around all you want! So, please do so if you like

But I really don't think there is much room for improvement here.

First off, we are really constrained by code space, so the implementation needs to be really efficient (not fast, but few instructions). This limits the freedom you have to get creative.

Secondly, I'm sure you have had a look at the characteristics of the NTC. Around 25C the curve is pretty linear and accuracy is pretty good. This already works for us. As we deviate further from 25C, yes, the curve will be more linear again, but by that point, accuracy is pretty much shot.

The 0.5C accuracy of the probe, I think is mainly manufacturing tolerances and will mostly be static error. You also have the 10k resistor for the voltage divider, that introduces a possible error.

Bottom line is, I don't think the current

implementation is the bottleneck.

What

might be done, is some better analysis of the lookup points around the 'knees' of the curve. There might be one or two lookup points, that could give better overall linearisation if they were 'nudged'. But these would probably just change 0.1 deg, and you'd need to make sure this improves the linearisation, and I'm not sure it would. Even this would be such a marginal improvement and probably outside the range of fermentation.

You'd probably be better off trimming the 10k resistor, and procuring a probe with low statical error if you want better accuracy.

But still, do play around! Who knows, right

More eyes on the code never hurt!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)