Not sure if this is of interest to you, but I made these two LUTs for the standard STC-1000 NTC while I was creating the LUTs for the Grainfather NTC:

This one is 0*C - 93*C with 3*C increments:

Code:0.0 27340 3.0 23800 6.0 21200 9.0 18750 12.0 16600 15.0 14700 18.0 13100 21.0 11600 24.0 10400 27.0 9300.0 30.0 8300.0 33.0 7500.0 36.0 6700.0 39.0 6000.0 42.0 5450.0 45.0 4900.0 48.0 4450.0 51.0 4040.0 54.0 3660.0 57.0 3330.0 60.0 3015.0 63.0 2745.0 66.0 2505.0 69.0 2290.0 72.0 2100.0 75.0 1925.0 78.0 1770.0 81.0 1625.0 84.0 1500.0 87.0 1380.0 90.0 1280.0 93.0 1180.0

This one is 6*C to 37*C with 1*C increments:

Code:6.0 21200 7.0 20300 8.0 19500 9.0 18750 10.0 18000 11.0 17300 12.0 16600 13.0 15900 14.0 15300 15.0 14700 16.0 14150 17.0 13600 18.0 13100 19.0 12600 20.0 12100 21.0 11600 22.0 11200 23.0 10800 24.0 10400 25.0 10000 26.0 9600.0 27.0 9300.0 28.0 9000.0 29.0 8650.0 30.0 8300.0 31.0 8050.0 32.0 7750.0 33.0 7500.0 34.0 7200.0 35.0 6950.0 36.0 6700.0 37.0 6500.0

I use the second one with my dual probe STC-1000+ on my fermenation fridge and tested it within those temps using water and a Thermopen.

Cheers,

Kal

With your themistor dialed in like that you'll get very precise control.

I had a look between 0 and 5 degrees, and the error of approximation only increased by around 0.01 deg C for 5 degree increments.

I tested a handfull of ebay B(25/85) 3435 thermistors at as close to 0 as I could get. In the same temperature water, each was with 0.1K ohm. I don't have precise enough measuring equipment to draw solid conclusions or to reference the resistance to a particular temperature. But, from the small sample size, the 5 for $5 temperature probes are excellent value for money and do an awesome job.

I began collecting data to the curves for different thermistors. So far this is what I have found. The curve needs to be as flat as possible in the temperature range of interest to provide reliable results. The 3435 probe that is readily available has a curve that seems very good for the temperature range home brewers are interested in.

The other thermistor that seems readily available has a beta(25/50) of 3950. The ebay ones do not seem to quote the (25/50) part though, but it seems to be targeted at ardunio users. The adafruit branded probe has data, but it is not in a format I can readily rip out the data to look at.

I like curves.... can you tell?:fro:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

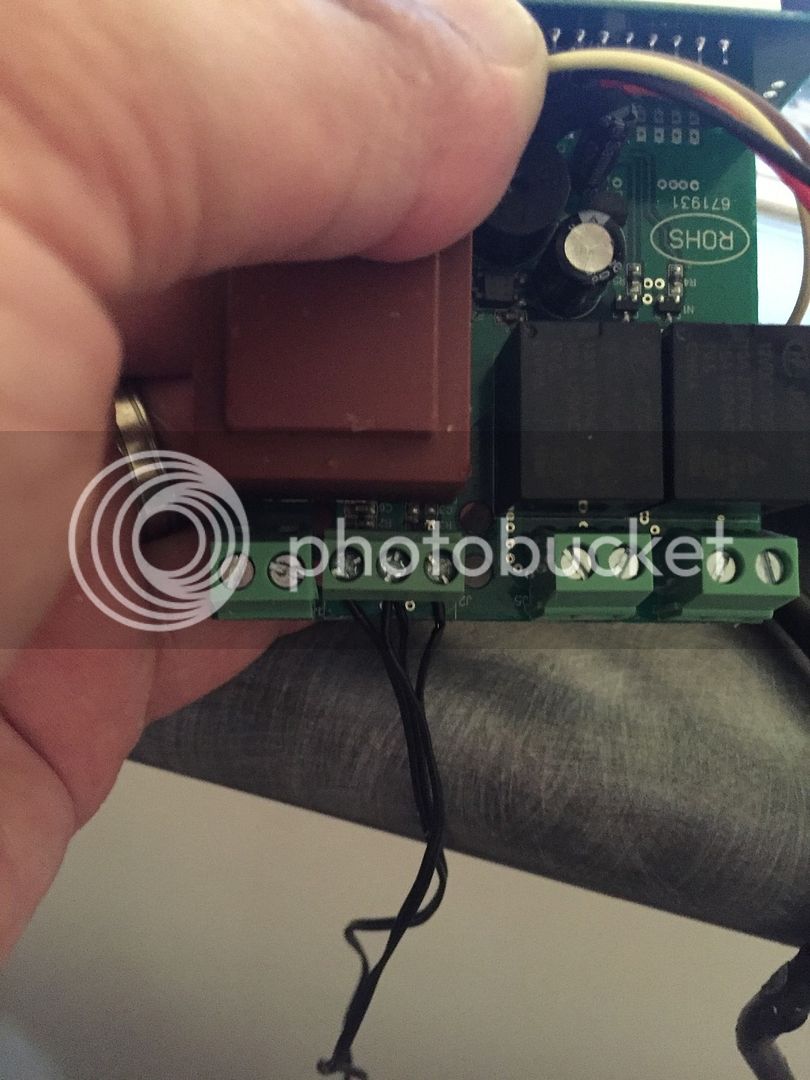

![IMG_20151201_145305813[1].jpg IMG_20151201_145305813[1].jpg](https://cdn.homebrewtalk.com/data/attach/272/272300-IMG-20151201-145305813-1-.jpg)

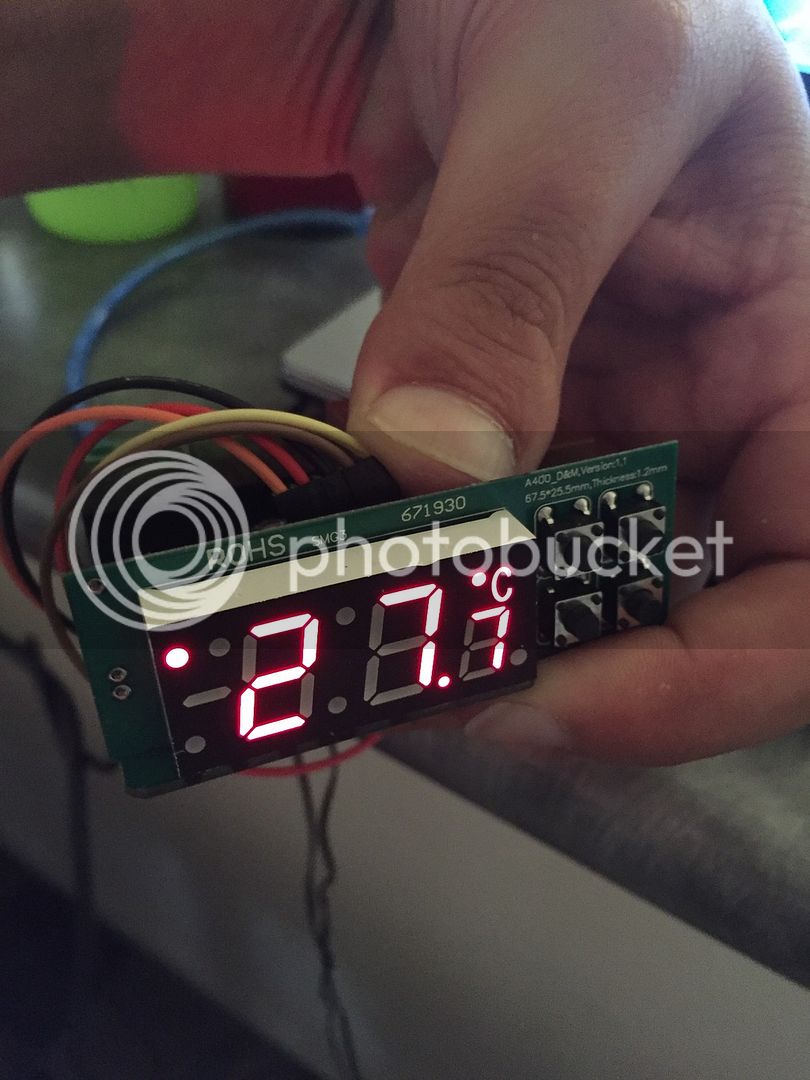

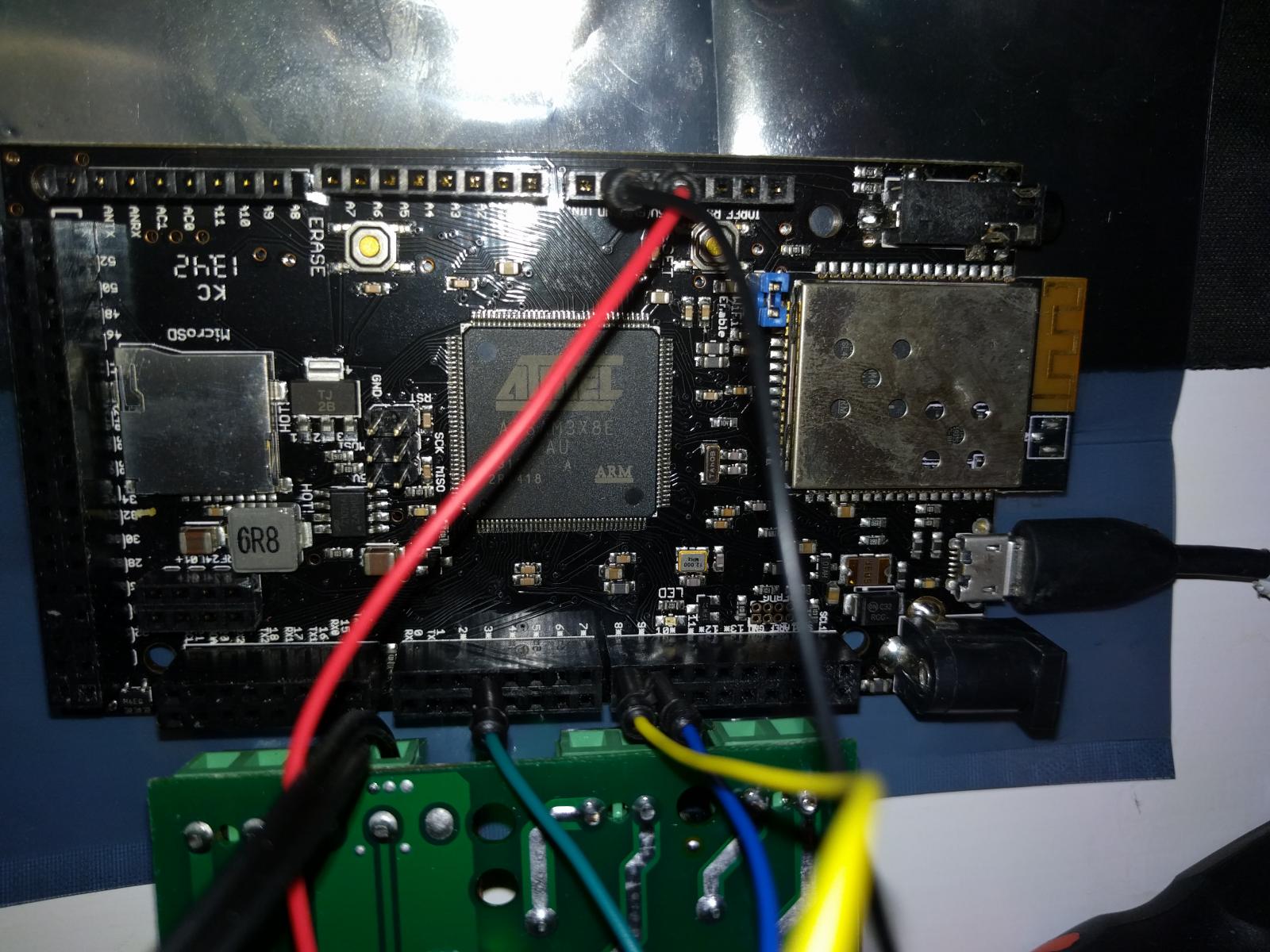

![IMG_20151024_120616208[1].jpg IMG_20151024_120616208[1].jpg](https://cdn.homebrewtalk.com/data/attach/272/272301-IMG-20151024-120616208-1-.jpg)

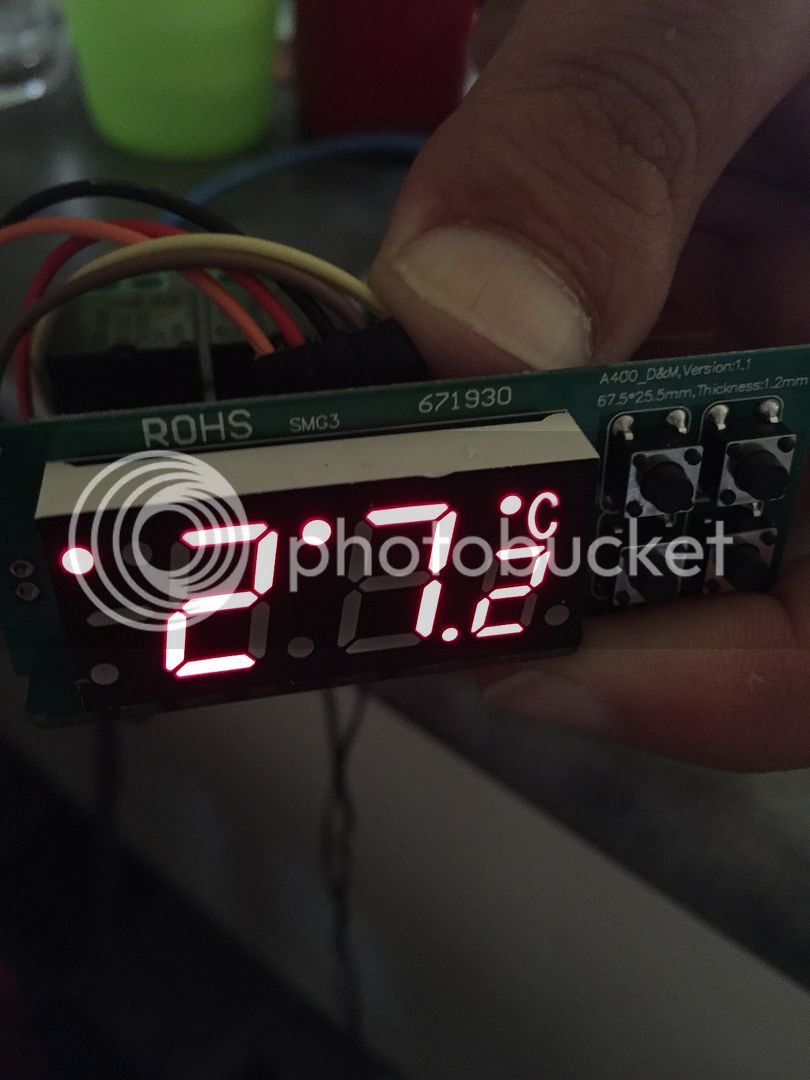

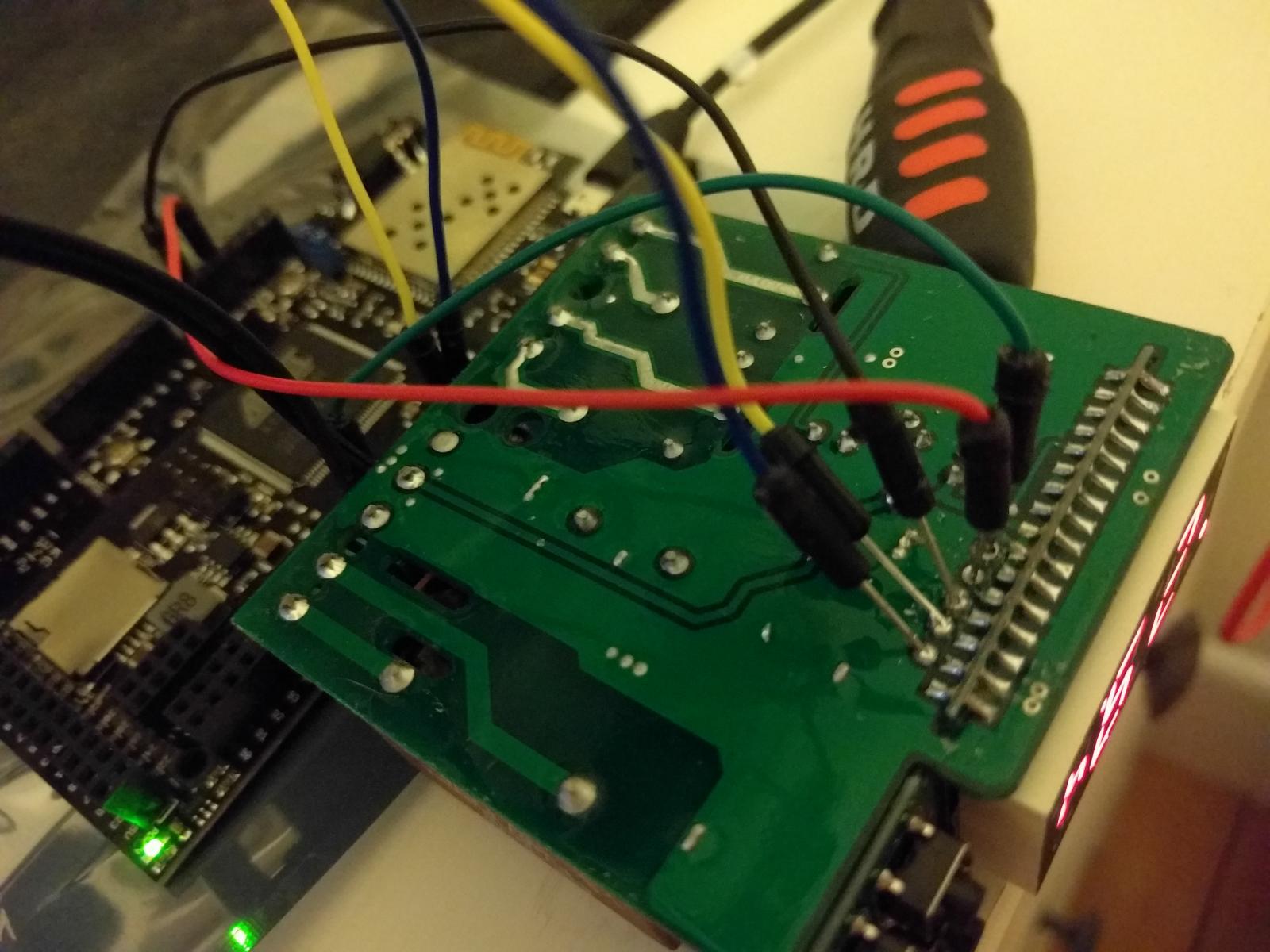

![IMG_20151115_184014148[1].jpg IMG_20151115_184014148[1].jpg](https://cdn.homebrewtalk.com/data/attach/272/272302-IMG-20151115-184014148-1-.jpg)