Okay so everythings working out well except cutting the square hole out for the screen.

Having drills, bits, a jig saw (but no blade), a coping saw, two table saws, and a thick rusty hand saw.

Tried cutting through with a work blade (xacto style). PITA!

Tried drilling circular holes into the corners, and using the coping saw. Too difficult and unsteady to cut straight. Ended up terrible.

Should I just go buy a new jig saw blade tomorrow?

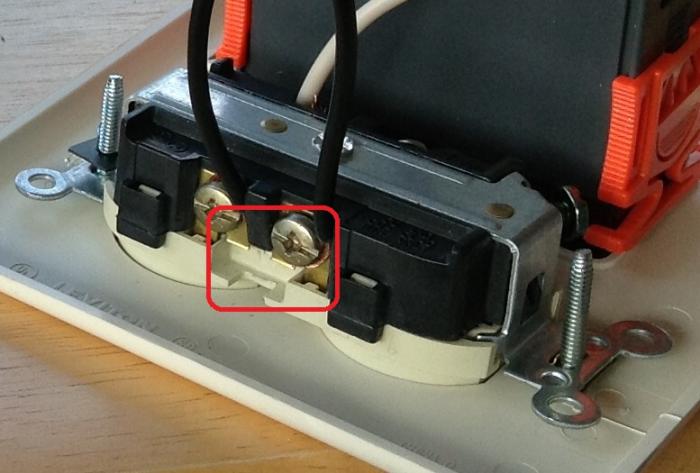

Do I need to sand/file down the edges of the drill holes so they don't scrape the extension cord parts, or don't worry too much about it?

I've made mine yesterday and its working fine!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)