- Joined

- Nov 26, 2006

- Messages

- 3,996

- Reaction score

- 94

Monster Mash said:Where do you get a copper X fitting?

The stainless braid acts as "hard piping" due to the liquid following the path of least resistance. Whatever liquid that is inside the braid will flow out because the grain that is pressed against the outside causes resistance. It works the same with slotted copper tubing.

But even with slotted copper tubing, it is advantageous to have the shortest possible route out of the brewkettle.

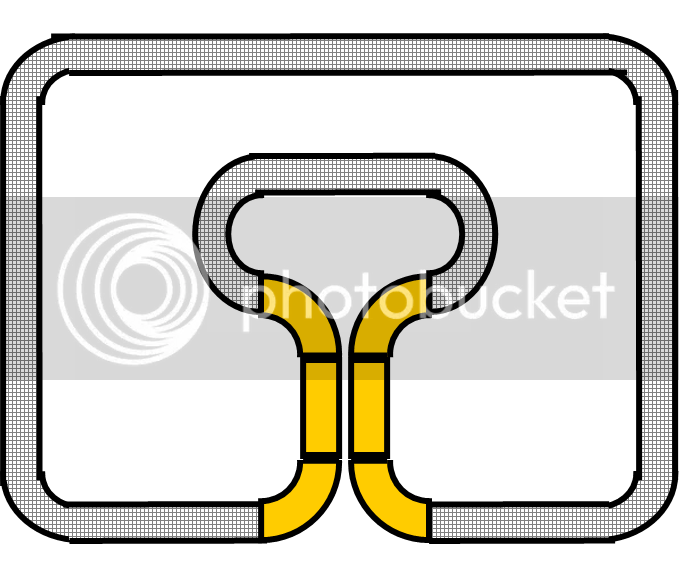

An X fitting is just a 4-way fitting. The T is 3 and the X is 4.... just rotated 45 degrees. As for where you get one, if you can't find one, then you can make one from two T fittings stuck together.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)