OK, this is long, and there are pics, but for anyone who's contemplating temp control using the freezer compartment of a refrigerator...this may give you some ideas.

Just bought a Spike CF10. Also bought the temp control kit. Seems a little pricey for what it is, but on the other hand, it's designed to fit.

The question was how to enable cold water/cold solution chilling ability. I'm tapped out--I can't afford, at the moment, any kind of glycol chiller. Certainly not a Penguin, and not even the ones for aquariums. So it has to be done with either icewater in a cooler or using a cold-solution reservoir in a freezer.

I chose the freezer option.

One issue is what kind of vessel will hold the solution. I have a gallon of Glycol, mixed w/ 2 gallons of water...I need at least three gallon capacity. But I wanted a larger vessel.

I found a plastic tub with 18 quarts of capacity at the home store; I felt that would give me enough capacity for the 3 gallons of solution, plus I wanted the thinnest rectangular area possible so it would shed heat as readily as possible. I set it on two half-bricks to lift it off the bottom of the freezer so cold air can circulate on all sides.

What you see in the pics below is a somewhat smaller tub I used for a trial run with just water. Actually screwed up and it froze on me at one point, had to add hot water to thaw the ice in the lines. C'est la vie. The tub I have includes a lid, into which I cut a slot to allow for capping the reservoir. Easy to remove. Not sure if it makes more sense to leave it off in the freezer or not. Probably try it with first.

************

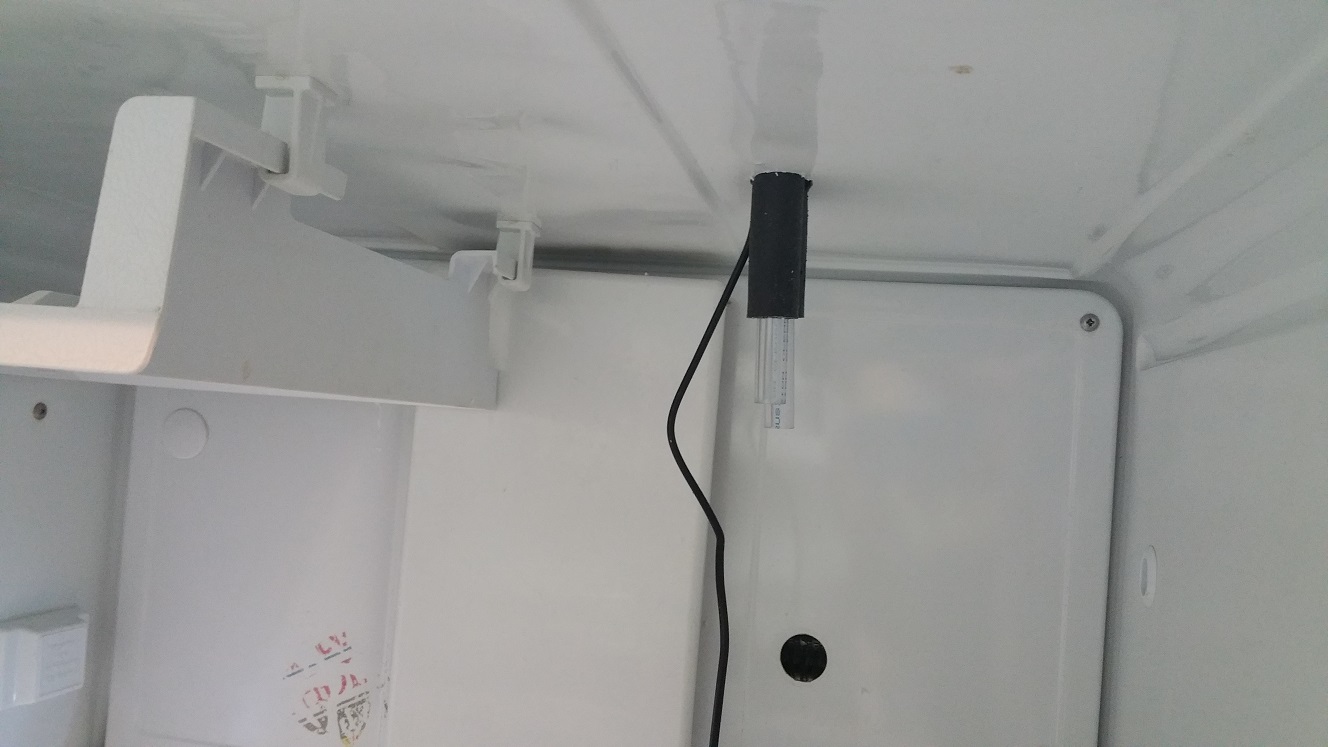

I chose the location on top of the fridge--which looks strange actually as you'd think the best place would be on a corner or the edge--because it allowed the lines to drop straight down to where the pump is. There's enough resistance to bending in those lines that I felt the pump would likely end up cockeyed if the lines were not dropped straight in. I could have, I suppose, found some sort of thin metal I could have bent to force a bend that would have worked, but this seemed simpler.

I bought a sheet-metal drill bit that maxed out at 3/4" diameter, drilled the two holes you see. I did the usual drill a small hole and probe w/ a piece of coat hanger to ensure there were no lines in the way....I would have bet you $500 there weren't, but if I'd hit one, finding another refrigerator of the same size, etc. would have been nigh impossible--and pricey.

The neoprene covering the vinyl tubing is about 3/4" in diameter--but it also has a little webbing piece connecting the two. This is good, it keeps the two lines together, BUT.....how do you drill a kind of figure-8 hole with a "waist" as well? I drilled the two holes and used my dremel tool to essentially connect the two holes. With the narrow waist between the holes I just couldn't get the tubing through there--it caught on the inside edges of the hole leading into the freezer compartment. So I widened them up into essentially an oval. You can see that in the one pic showing the extra space where the tubes go into the top--there's an arrow pointing to it.

As it turns out, that was a good thing--it provides a space through which the power line for the pump can pass, and the other side for the temp probe from the inkbird. Sometimes you get lucky.

****************

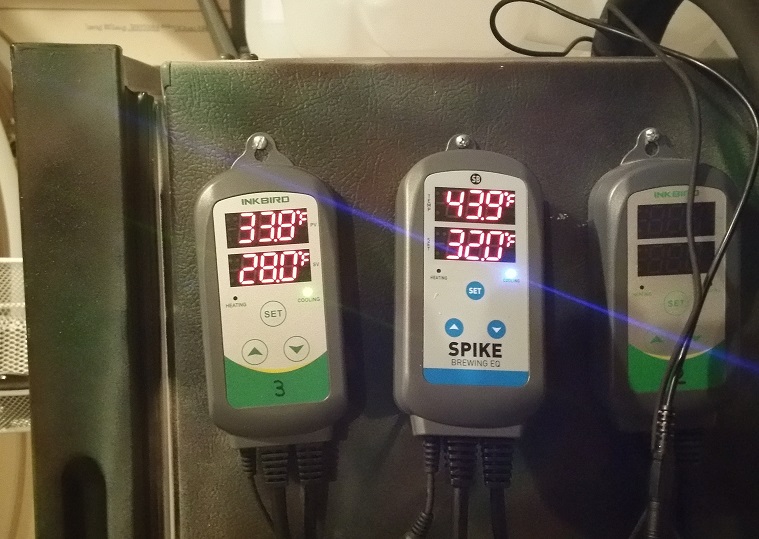

So, all that was left was seeing if it worked. I added 6+ gallons of Star-San solution to the conical, turned on the heater; found that it could take the temp up about 4 degrees in a half hour--which is just fine to keep things warm in the winter, or raise the temp for a diacetyl rest or just to let the yeast finish. So that works.

Then it was the cooling part. Installed the cooling coil, connected the lines, filled the reservoir with water, turned on the pump....and water starts spraying from one of the John Guest fittings connecting the tubing to the coil. Turn off, reconnect, turn on--and things are better. But one is still dripping. Disconnect, reconnect--I think I know how to do that now--and got it to work with no leaks.

The pump runs water through at a pretty good pace. All that will matter is whether there's enough thermal mass in the cooling solution--and recovery capacity with the freezer--to run this down to cold crash levels. We'll see. In the meantime, I have a way to do normal temp control that cost me $6 for the plastic tub and $10 for the drill bit. And $30 for the Propylene Glycol.

********

I was ready to brew today and then realized I forgot to bring the garden hose inside. It was in the teens last night, so I have a hose which is 50 feet of coiled ice. Maybe later...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)