dont know if this will help but i have the 30gal system and im still dialing it in, my boil off rate is about 1.5 gallon on average. 60min boil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spike Complete System

- Thread starter NCBeerMedic

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Spike had me take some measurements on the coil and they've decided to send me a replacement. I'll measure the ends to compare with the old one before installing it. Hopefully this fixes my issue.

flyerwire

Well-Known Member

Hi all, phew, spent some time reading this thread and about to pull the trigger on a spike system (20G?) but have a few questions from this thread. thanks to all who have contributed here

1) Chiller, would anyone recommend a different chiller? A $400 chiller seems a bit crazy.

2) I have about 70" of space which is keeping me at the 20G system. I was hoping to do 1/2bbl but don't think i can squeeze all three 30G in that space?

3) Pumps. Was thinking of not getting the chuggers and replacing with riptides. Have to talk to Spike to see what the costs of not having them in the package is. I brew in an enclosed space with people usually around and the riptides are so much quieter. Have the chuggers been working fine?

Any other changes anyone would make after using it for a while?

1) Chiller, would anyone recommend a different chiller? A $400 chiller seems a bit crazy.

2) I have about 70" of space which is keeping me at the 20G system. I was hoping to do 1/2bbl but don't think i can squeeze all three 30G in that space?

3) Pumps. Was thinking of not getting the chuggers and replacing with riptides. Have to talk to Spike to see what the costs of not having them in the package is. I brew in an enclosed space with people usually around and the riptides are so much quieter. Have the chuggers been working fine?

Any other changes anyone would make after using it for a while?

Hi all, phew, spent some time reading this thread and about to pull the trigger on a spike system (20G?) but have a few questions from this thread. thanks to all who have contributed here

1) Chiller, would anyone recommend a different chiller? A $400 chiller seems a bit crazy.

2) I have about 70" of space which is keeping me at the 20G system. I was hoping to do 1/2bbl but don't think i can squeeze all three 30G in that space?

3) Pumps. Was thinking of not getting the chuggers and replacing with riptides. Have to talk to Spike to see what the costs of not having them in the package is. I brew in an enclosed space with people usually around and the riptides are so much quieter. Have the chuggers been working fine?

Any other changes anyone would make after using it for a while?

Hello flyerwire, here are my findings for my setup.

1 - In regards to the chiller I went with the same type chiller from More Beer and found out I saved about $80 bucks by doing so.

2 - You might could do all 30 gallon kettles in 70" but it would be tight. Thr kettles are 19.7" in diameter not counting handles and handle to handle is 24.5" (drawing attached)

3 - I also opted to go go with RipTide pumps as well and as I recall it wound up saving me some cash by doing so and I set those up the same way and ordered all of the hardware and valves from them and Brewhardware combined.

Hope this helps

Attachments

flyerwire

Well-Known Member

Hello flyerwire, here are my findings for my setup.

1 - In regards to the chiller I went with the same type chiller from More Beer and found out I saved about $80 bucks by doing so.

2 - You might could do all 30 gallon kettles in 70" but it would be tight. Thr kettles are 19.7" in diameter not counting handles and handle to handle is 24.5" (drawing attached)

3 - I also opted to go go with RipTide pumps as well and as I recall it wound up saving me some cash by doing so and I set those up the same way and ordered all of the hardware and valves from them and Brewhardware combined.

Hope this helps

definitely. With handles that would go edge to edge. I’ll stick with filling 2 sixtels from a batch + loss instead of going 1/2bbl and save some counter room.

i have an old CFC I’ll grab some fittings for and see how that works before I buy another. This is already getting into my high budget range! (But now I’ll just buy a glycol chiller!)

I have 1 riptide, I’ll grab another and a TC to NPT and can have it plug and play. Now to just bother Ryan yet again before I order

definitely. With handles that would go edge to edge. I’ll stick with filling 2 sixtels from a batch + loss instead of going 1/2bbl and save some counter room.

i have an old CFC I’ll grab some fittings for and see how that works before I buy another. This is already getting into my high budget range! (But now I’ll just buy a glycol chiller!)

I have 1 riptide, I’ll grab another and a TC to NPT and can have it plug and play. Now to just bother Ryan yet again before I order

Ryan was who helped me so much when I got mine, very helpful.

one thing to keep in mind if you want any special ports get them added now. When they were doing mine I had them add a port on the side of the brew kettle so I could use a steam slayer.

Cheers and happy brewing

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

Brewfreedom

Well-Known Member

- Joined

- Jul 29, 2018

- Messages

- 155

- Reaction score

- 63

Went w stout stainless chiller. Was much cheaper. Love it. Went w diff/cheaper pumps. You can always just get the kettles. They are big so 70 inches will be real close.

Hi all, phew, spent some time reading this thread and about to pull the trigger on a spike system (20G?) but have a few questions from this thread. thanks to all who have contributed here

1) Chiller, would anyone recommend a different chiller? A $400 chiller seems a bit crazy.

2) I have about 70" of space which is keeping me at the 20G system. I was hoping to do 1/2bbl but don't think i can squeeze all three 30G in that space?

3) Pumps. Was thinking of not getting the chuggers and replacing with riptides. Have to talk to Spike to see what the costs of not having them in the package is. I brew in an enclosed space with people usually around and the riptides are so much quieter. Have the chuggers been working fine?

Any other changes anyone would make after using it for a while?

1) I've been using a Therminator for chilling to my conical with great success. Didn't pay $400 though.

2) I also have a 20 gallon Spike set up, which is on a 60" table (see pic). This is a bit tight, but works well, especially as it butts up against a 24" deep side table in case I need to borrow a little more space. Also, my kettle handles are on the sides, which take up more room than you might think. The new Spike design, using front/back handles, frees up more space although they maybe not as easy to move around since one handle is in the back. I don't have the dimensions of the 1/2 barrel system, but with 70 inches (and if they have front/back handles) I think it might work fine. But measure twice...

3) I use a pair of RipTides, and they have been pretty good. They have given me occasional fits with priming, but I always get them working ... eventually. Biggest issue was an impeller failure mid-brew right at the end of my mash (at 149F), which caused some panic as I needed to mash out then fly sparge. Hard to do with one pump! I ended up shifting to a makeshift batch sparge which got me there, but was not ideal. These impellers have a history, and Blich had to redesign them a few years ago. I have the newer design, but it nevertheless failed without warning. Although a few weeks out of warranty, Blich stepped up and replaced it. Nice and appreciated, but I could have had a lost/bad brew. Lesson: buy insurance by purchasing a spare impeller and other "wear" parts that might go bad so you can repair on the fly. $40 worth of spares is a reasonable investment to help get you out of a jam when needed (considering your overall investment and time/effort/cost of a brew session).

flyerwire

Well-Known Member

View attachment 676490

1) I've been using a Therminator for chilling to my conical with great success. Didn't pay $400 though.

2) I also have a 20 gallon Spike set up, which is on a 60" table (see pic). This is a bit tight, but works well, especially as it butts up against a 24" deep side table in case I need to borrow a little more space. Also, my kettle handles are on the sides, which take up more room than you might think. The new Spike design, using front/back handles, frees up more space although they maybe not as easy to move around since one handle is in the back. I don't have the dimensions of the 1/2 barrel system, but with 70 inches (and if they have front/back handles) I think it might work fine. But measure twice...

3) I use a pair of RipTides, and they have been pretty good. They have given me occasional fits with priming, but I always get them working ... eventually. Biggest issue was an impeller failure mid-brew right at the end of my mash (at 149F), which caused some panic as I needed to mash out then fly sparge. Hard to do with one pump! I ended up shifting to a makeshift batch sparge which got me there, but was not ideal. These impellers have a history, and Blich had to redesign them a few years ago. I have the newer design, but it nevertheless failed without warning. Although a few weeks out of warranty, Blich stepped up and replaced it. Nice and appreciated, but I could have had a lost/bad brew. Lesson: buy insurance by purchasing a spare impeller and other "wear" parts that might go bad so you can repair on the fly. $40 worth of spares is a reasonable investment to help get you out of a jam when needed (considering your overall investment and time/effort/cost of a brew session).

Thanks, yeah I have an old CFC i can keep using, just have to adjust some fittings. I'll repurpose that money into a glycol chiller (either purchase or make my own).

Thanks for the note on them changing the handles to front back, without handles they are roughly 20" wide, which would be at 60" and give no spacing. Even though they will technically fit without the handles on the side I'm just going to stick with the 20G, would rather have some space on the table for random stuff then have every inch full (you always need room for random crap everywhere!). Plus with the CF15's that gives me the ability to put 13G minimum into the fermenter to fill 2 sixtels with extra loss for yeast reclamation and trub drops.

I was close to starting construction on a taproom and was denied zoning by the local township about 2 weeks before this covid-19 shutdown started in the northeast (I was very pissed for 2 weeks but now have a gigantic sigh of relief and will find a new place when things clear up) so will repurpose this into a pilot system at that point so the TC system is very convenient. That was the main driver behind 1/2bbl, but can do the same on a 20G

Yep, agree with the value of real estate, as you can never have too much flat space. I also have a 48-inch SS folding table (heavy and stable) that I set up on the left side on brew days, and I use the heck out of it. I've prolly become less efficient, but at least it's more comfy than when I was working in the M.E. and did everything in a (tiny) kitchen!

BTW, I can easily fill a 13-gallon batch in my CF-10. Granted, not a lot of head space, but that has not been a problem so far. Maybe if I tried a heavy brew with a huge krausen it might give the blow off cane a workout, we will find out one day! If you already have a CF-15, then that's great. I think it has the same footprint.

BTW, I can easily fill a 13-gallon batch in my CF-10. Granted, not a lot of head space, but that has not been a problem so far. Maybe if I tried a heavy brew with a huge krausen it might give the blow off cane a workout, we will find out one day! If you already have a CF-15, then that's great. I think it has the same footprint.

flyerwire

Well-Known Member

Yep, agree with the value of real estate, as you can never have too much flat space. I also have a 48-inch SS folding table (heavy and stable) that I set up on the left side on brew days, and I use the heck out of it. I've prolly become less efficient, but at least it's more comfy than when I was working in the M.E. and did everything in a (tiny) kitchen!

BTW, I can easily fill a 13-gallon batch in my CF-10. Granted, not a lot of head space, but that has not been a problem so far. Maybe if I tried a heavy brew with a huge krausen it might give the blow off cane a workout, we will find out one day! If you already have a CF-15, then that's great. I think it has the same footprint.

thanks, i got the 15's just for flexibility and they take up the same space. Grabbed 2 which should be enough if I can properly schedule after the first few batches.

Now i need to search back through the thread to start building a profile for the setup. Haven't really done in depth work with brewfather besides recipe management, but I love it... i'll see what the equipment side is like.

thanks, i got the 15's just for flexibility and they take up the same space. Grabbed 2 which should be enough if I can properly schedule after the first few batches.

Now i need to search back through the thread to start building a profile for the setup. Haven't really done in depth work with brewfather besides recipe management, but I love it... i'll see what the equipment side is like.

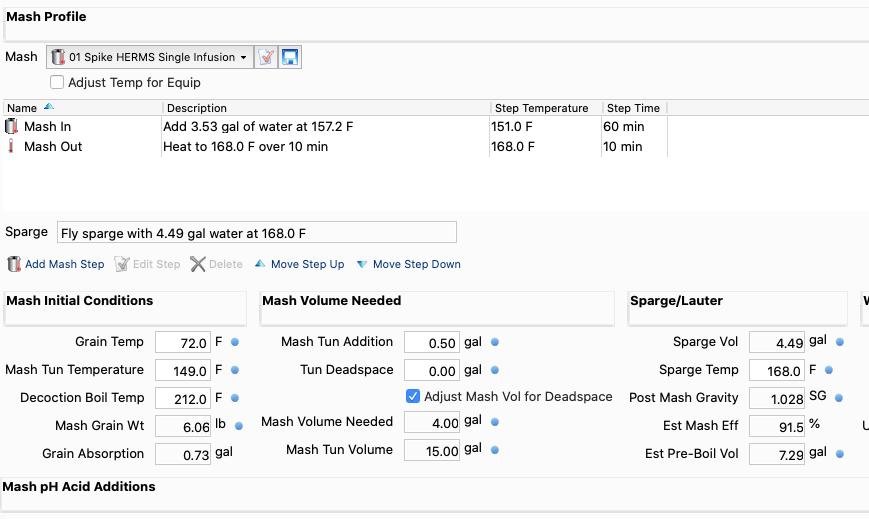

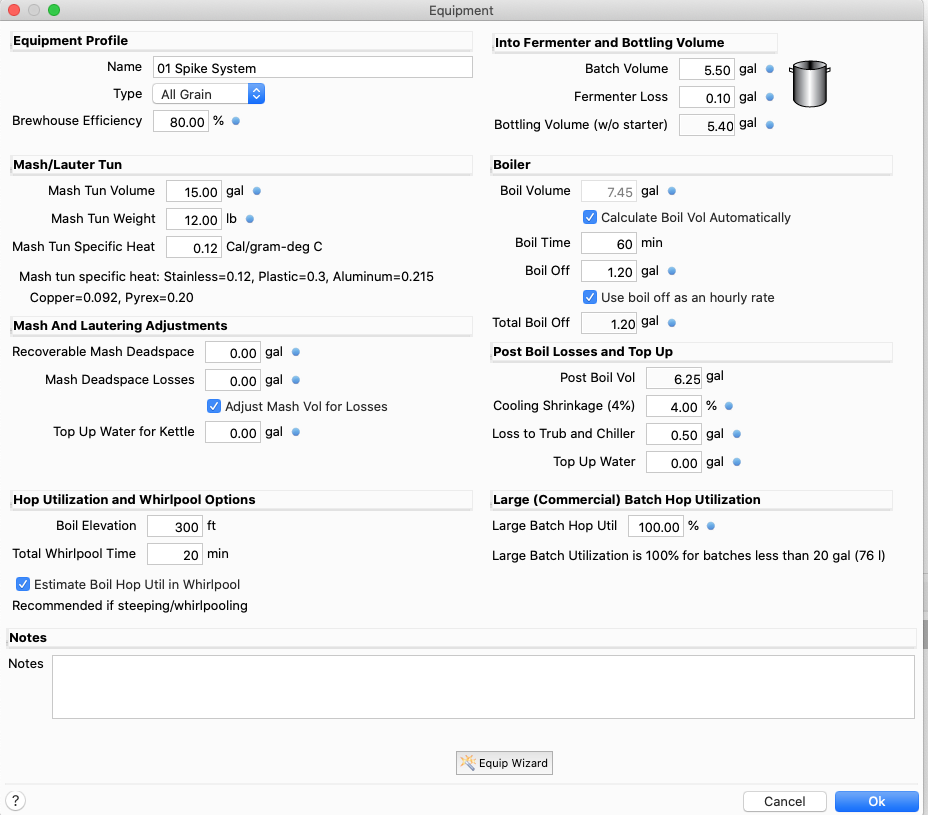

Hope these help. I recommend setting your efficiency at 75% to start, I've gradually raised mine as I have gotten to know the system. Get yourself a set of good feeler gauges and measure your crush at 0.045" - it made all the difference for me. I was crushing much too fine at first 0.030, and then much to coarse (0.060) trying to dial in efficiency. 0.045 is really the sweet spot and you can run your mash recirc at a reasonable speed and still get 90%% mash efficiency.

Another useful datapoint to check is your first-runnings gravity, which is entirely a function of your mash thickness and conversion efficiency. Brukaiser published a table here. Don't forget to account for the volume of water in your lines when calculating mash thickness - it's a little more than 1/2 gallon for me and makes a difference.

flyerwire

Well-Known Member

Hope these help. I recommend setting your efficiency at 75% to start, I've gradually raised mine as I have gotten to know the system. Get yourself a set of good feeler gauges and measure your crush at 0.045" - it made all the difference for me. I was crushing much too fine at first 0.030, and then much to coarse (0.060) trying to dial in efficiency. 0.045 is really the sweet spot and you can run your mash recirc at a reasonable speed and still get 90%% mash efficiency.

Another useful datapoint to check is your first-runnings gravity, which is entirely a function of your mash thickness and conversion efficiency. Brukaiser published a table here. Don't forget to account for the volume of water in your lines when calculating mash thickness - it's a little more than 1/2 gallon for me and makes a difference.

View attachment 676816 View attachment 676813 View attachment 676814

awesome, thank you! and noted on the water in lines, which i'm sure i would have forgotten about the first time

i think I have mine set somewhere between .045 and .050, will have to double check it.

Hope these help. I recommend setting your efficiency at 75% to start, I've gradually raised mine as I have gotten to know the system. Get yourself a set of good feeler gauges and measure your crush at 0.045" - it made all the difference for me. I was crushing much too fine at first 0.030, and then much to coarse (0.060) trying to dial in efficiency. 0.045 is really the sweet spot and you can run your mash recirc at a reasonable speed and still get 90%% mash efficiency.

Another useful datapoint to check is your first-runnings gravity, which is entirely a function of your mash thickness and conversion efficiency. Brukaiser published a table here. Don't forget to account for the volume of water in your lines when calculating mash thickness - it's a little more than 1/2 gallon for me and makes a difference.

View attachment 676816 View attachment 676813 View attachment 676814

Mad King, I have a question for you since you sort of bought it up. When you are finished with the mash what is your procedure for transfering your wort to the BK? Meaning, are you doing a nash out? Do you drain the the mashtun and transfer to the BK before you add any water to the mashtun OR do you add water to the mashtun and start the transfer almost the same?

I have been adding water to the mashtun to keep about an inch of water over the grain then I'd start the transfer. Before that I'd do a mash out.

please share

flyerwire

Well-Known Member

Mad King, I have a question for you since you sort of bought it up. When you are finished with the mash what is your procedure for transfering your wort to the BK? Meaning, are you doing a nash out? Do you drain the the mashtun and transfer to the BK before you add any water to the mashtun OR do you add water to the mashtun and start the transfer almost the same?

I have been adding water to the mashtun to keep about an inch of water over the grain then I'd start the transfer. Before that I'd do a mash out.

please share

I'm not Mad King, but you wouldn't want to compact your grain bed by draining the water out of your mash tun. At most you would want to start pulling to your BK slowly and then try to match that rate with your sparge in order to keep a good inch of water over your grain bed.

I don't have my Spike system yet, but generally i would do what you are doing. Mash / Mash Out / start pump slowly to transfer from MT to BK, then start pump from HLT to MT for sparging.

I'm not Mad King, but you wouldn't want to compact your grain bed by draining the water out of your mash tun. At most you would want to start pulling to your BK slowly and then try to match that rate with your sparge in order to keep a good inch of water over your grain bed.

I don't have my Spike system yet, but generally i would do what you are doing. Mash / Mash Out / start pump slowly to transfer from MT to BK, then start pump from HLT to MT for sparging.

That is what I have been doing but thought I'd ask. I saw a brewer do what I spoke about on a pilot system about a year ago and have always wondered. But as I said I sort of follow close to what you said.

Mad King, I have a question for you since you sort of bought it up. When you are finished with the mash what is your procedure for transfering your wort to the BK? Meaning, are you doing a nash out? Do you drain the the mashtun and transfer to the BK before you add any water to the mashtun OR do you add water to the mashtun and start the transfer almost the same?

I have been adding water to the mashtun to keep about an inch of water over the grain then I'd start the transfer. Before that I'd do a mash out.

please share

I normally start my sparge with 168F water just a couple minutes after I start runoff. I try not to let the liquid level drop below the grain bed for a couple reasons, first it compacts the grain bed as others have mentioned, second it has been mentioned as a significant source of oxidation (oxidizing compounds in the grain and then washing them into your beer with the sparge water) - so as a matter of "good practice" I try to keep at least 1" of water over the top of the grain bed.

a slow runoff and sparge does increase efficiency. I don't have a flow meter, but I usually will try to introduce sparge water slowly enough that it does not cause significant mixing of clear water and wort (i.e. there's a layering effect of clear water sitting on top of denser wort), and try to match my runoff to that.

All of that said, if I'm doing a big beer then I'll switch to batch sparging because I need the efficiency boost - you loose wort clarity into the kettle, but I'll take that over 55% efficiency on a barleywine any day.

I normally start my sparge with 168F water just a couple minutes after I start runoff. I try not to let the liquid level drop below the grain bed for a couple reasons, first it compacts the grain bed as others have mentioned, second it has been mentioned as a significant source of oxidation (oxidizing compounds in the grain and then washing them into your beer with the sparge water) - so as a matter of "good practice" I try to keep at least 1" of water over the top of the grain bed.

a slow runoff and sparge does increase efficiency. I don't have a flow meter, but I usually will try to introduce sparge water slowly enough that it does not cause significant mixing of clear water and wort (i.e. there's a layering effect of clear water sitting on top of denser wort), and try to match my runoff to that.

All of that said, if I'm doing a big beer then I'll switch to batch sparging because I need the efficiency boost - you loose wort clarity into the kettle, but I'll take that over 55% efficiency on a barleywine any day.

That is basically my procedure as well but thought I'd ask since you had some more brews under your belt.

You have intrigued me with the .045" crush, I have been doing .038" and I am going to give the new setting a try and see what happens. Thanks for sharing and I'll share my results when I try it as well.

Cheers!

- Joined

- Dec 5, 2014

- Messages

- 255

- Reaction score

- 53

This right here, I finally brewed 3 batches on my new Spike system. First batch had a few issues, mainly due to equipment profile in BS.I had this issue, and raised it with Spike who said that I probably didn't have the connections pushed in all the way. I am 100% sure that I did, and after thinking about it, I am pretty sure I know the root cause of the problem. The standard configuration is to have valves on either end of the HERMS. If you ever have the HERMS filled with liquid and both valves closed, and then heat your HLT, then the trapped water will expand. With the fluid being essentially incompressible, it has nowhere to go but to begin pushing out the HERMS from its fittings. Liquid expands about 3.5-4% from 70-200F, and so there is no doubt this can happen. I described this to Spike, but they said they had never seen this before. But trust me, it is real, and it happened to me again (because I am a dufus and accidently let it happen again!).

To solve this potential problem (i.e. idiot-proof the system), I removed the valve from the top HERMS connection. I also removed the top valve from the MT port (since you typically will have a hose connecting the two), otherwise you can still be exposed to this "trapped liquid" situation. In most situations, you really don't need to ever isolate the HERMS on each end and don't need these valves.

Hope this helps you in case that was your issue.

Brewed Saturday, my second batch. Had a great mash, hit my numbers spot on, even a little higher. Well after I sparged and and had my BK filled I noticed I was short on volume. Sure enough I look in my HLT to make sure I pulled the correct volume. I must have lost about 1.5 gallons through the herms coil. Thought I must have pulled it out by mistake. Today I brewed and made sure it was fully inserted. While cleaning up I noticed water shooting out the fitting again. Must have happened while heating up my PBW. I did notice some pressure when I opened the valve on the coil. Didn't think about that.

Anyway thanks for figuring it out, I was about to switch out the PTC fittings.

Last edited:

Thanks. This was the issue for sure, at least for me. Many batches later, I've had zero problems with this.This right here, I finally brewed 3 batches on my new Spike system. First batch had a few issues, mainly due to equipment profile in BS.

Brewed Saturday, my second batch. Had a great mash, hit my numbers spot on, even a little higher. Well after I sparged and and had my BK filled I noticed I was short on volume. Sure enough I look in my HLT to make sure I pulled the correct volume. I must have lost about 1.5 gallons through the herms coil. Thought I must have pulled it out by mistake. Today I brewed and made sure it was fully inserted. While cleaning up I noticed water shooting out the fitting again. Must have happened while heating up my PBW. I did notice some pressure when I opened the valve on the coil. Didn't think about that.

Anyway thanks for figuring it out, I was about to switch out the PTC fittings.

Brian allerton

Member

- Joined

- Apr 23, 2020

- Messages

- 18

- Reaction score

- 5

Can someone show me there beersmith equipment profile for the spike 30 gal system?

Summers

Well-Known Member

Question for the system owners that have the triclamp version, is the herms coil welded with triclamp and attached via triclamp on the inside or does the herms coil come with a different connection like that they offer for the NPT version?

Late reply I know but... The HERMS coil on the triclamp version uses "push to connect" fittings just like the NPT version. The differnce being: on the NPT version the push to connect fittings screw into the welded ports on the kettle. On the triclamp version they use a triclamp push to connect fitting. The coil itself mounts the same either way.

@TheMadKing Did you wind up going with the RipTide pumps or did you just keep your chugger pumps?

If you did go with the RipTides, how many revolutions out from close do you have them set when doing your mash recirculation?

2nd question, are you still using a 2qt per pound for doing your mash?

Thanks and cheers!

If you did go with the RipTides, how many revolutions out from close do you have them set when doing your mash recirculation?

2nd question, are you still using a 2qt per pound for doing your mash?

Thanks and cheers!

@TheMadKing Did you wind up going with the RipTide pumps or did you just keep your chugger pumps?

If you did go with the RipTides, how many revolutions out from close do you have them set when doing your mash recirculation?

2nd question, are you still using a 2qt per pound for doing your mash?

Thanks and cheers!

Yep I love my riptides.

I can't give you a good answer because the valve setting will be different for every batch depending on the size of your grain bill and grains you're using. You may need it open much more for a large grain bill with wheat in it than for a small all-barley grain bill to keep the same flow rate. AND I routinely have to adjust it mid-mash because the flow drops as the grain bed compacts a bit.

I plan on buying a flow meter eventually but right now I just eyeball the flow rate coming out of my return

I do prefer 2quarts/lb and seem to get the best efficiency at that ratio. I have tried between 1.25 and 3, and 2 seems to offer the best trade off of good recirculation with leaving a reasonable sparge volume.

Yep I love my riptides.

I can't give you a good answer because the valve setting will be different for every batch depending on the size of your grain bill and grains you're using. You may need it open much more for a large grain bill with wheat in it than for a small all-barley grain bill to keep the same flow rate. AND I routinely have to adjust it mid-mash because the flow drops as the grain bed compacts a bit.

I plan on buying a flow meter eventually but right now I just eyeball the flow rate coming out of my return

I do prefer 2quarts/lb and seem to get the best efficiency at that ratio. I have tried between 1.25 and 3, and 2 seems to offer the best trade off of good recirculation with leaving a reasonable sparge volume.

This might explain some of my flow problem / efficiency issues I have been using 1.33 qts per pound and it is hard to get good flow without having to turn the pump up. So guessing I am getting some channeling doing this since i have to turn the pump valve out 1 to 1.25 turns out to get it going. I am barely cracking by ball valve on the return recirc port on the MT though.

This might explain some of my flow problem / efficiency issues I have been using 1.33 qts per pound and it is hard to get good flow without having to turn the pump up. So guessing I am getting some channeling doing this since i have to turn the pump valve out 1 to 1.25 turns out to get it going. I am barely cracking by ball valve on the return recirc port on the MT though.

You should only be controlling flow with 1 valve at a time, so you're not gaining anything by using both the ball valve and the linear flow valve except possibly some added complexity

Open that ball valve wide open and only control flow with the riptide linear valve, since it has much finer control

You should only be controlling flow with 1 valve at a time, so you're not gaining anything by using both the ball valve and the linear flow valve except possibly some added complexity

Open that ball valve wide open and only control flow with the riptide linear valve, since it has much finer control

Will do, cause with more water it may be easier to control this way.

One more question:

when calculating how much water to add to your mash tun are you adding the water amount in your herms coil, and the water in the dead space under the false bottom to your overall volume?

Will do, cause with more water it may be easier to control this way.

One more question:

when calculating how much water to add to your mash tun are you adding the water amount in your herms coil, and the water in the dead space under the false bottom to your overall volume?

Yep I have a half gallon of recoverable dead space in my equipment profile to account for that.

Yep I have a half gallon of recoverable dead space in my equipment profile to account for that.

Thanks, going to give this a try my next brewday this Saturday.

Thanks, going to give this a try my next brewday this Saturday.

Good luck!

Good luck!

are you still just using a silicone hose on top of the grain bed during recirc?

are you still just using a silicone hose on top of the grain bed during recirc?

No I bought a locline aquarium return that I use now. It hasn't made a huge difference to be honest

No I bought a locline aquarium return that I use now. It hasn't made a huge difference to be honest

Thanks again, after reading what you have been doing and have found out tells me things on how I can improve. I have been using way to little of water during the mash and recirc for sure.

Sorry to swerve over to Riptides in this Spike discussion (for a moment), but since this has been raised I am reminded of a couple of related issued I have been wanting to explore with members:Yep I love my riptides.

I can't give you a good answer because the valve setting will be different for every batch depending on the size of your grain bill and grains you're using. You may need it open much more for a large grain bill with wheat in it than for a small all-barley grain bill to keep the same flow rate. AND I routinely have to adjust it mid-mash because the flow drops as the grain bed compacts a bit.

I plan on buying a flow meter eventually but right now I just eyeball the flow rate coming out of my return

I do prefer 2quarts/lb and seem to get the best efficiency at that ratio. I have tried between 1.25 and 3, and 2 seems to offer the best trade off of good recirculation with leaving a reasonable sparge volume.

1) I generally like the pump, as it is a solid piece of equip, but often struggle with getting it primed and running (esp. the wort pump, for which the fluid has a grain bed to flow through). I go through all the proper steps for positioning the pump (relative the kettles), plumbing/hosing (e.g. minimize length and bends), bleeding air, etc., but always have to baby it (sometimes a lot) to get it going. Do you have similar problems or, if not, do you have some tricks for priming?

2) You mention that the linear flow valve is good for making fine adjustments of rate. My experience is different, especially when fly sparging. At times I can make large turns and get little or no change in rate, then at other times I can only breathe on it and it changes tons. Makes fly sparging a very tedious 90-120 minutes (more than I would expect, even accounting for normal bed compaction, etc., during the sparge). Again, do you have any learnings that might improve this performance? Many thanks!

Sorry to swerve over to Riptides in this Spike discussion (for a moment), but since this has been raised I am reminded of a couple of related issued I have been wanting to explore with members:

1) I generally like the pump, as it is a solid piece of equip, but often struggle with getting it primed and running (esp. the wort pump, for which the fluid has a grain bed to flow through). I go through all the proper steps for positioning the pump (relative the kettles), plumbing/hosing (e.g. minimize length and bends), bleeding air, etc., but always have to baby it (sometimes a lot) to get it going. Do you have similar problems or, if not, do you have some tricks for priming?

2) You mention that the linear flow valve is good for making fine adjustments of rate. My experience is different, especially when fly sparging. At times I can make large turns and get little or no change in rate, then at other times I can only breathe on it and it changes tons. Makes fly sparging a very tedious 90-120 minutes (more than I would expect, even accounting for normal bed compaction, etc., during the sparge). Again, do you have any learnings that might improve this performance? Many thanks!

So on #1, I have installed an additional ball valve on the outlet of my wort Riptide which faces down toward the ground (a little different than Spike has it. When I prime it, I do the following:

- Start with the pump off

- put a bucket under it

- open the ball valve all the way,

- open the linear valve all the way

- and then open the kettle outlet to allow water/wort to flow through the line and pump out into the bucket

- As soon as you have a full line with no air bubbles, close the ball valve (I usually lose about 1-2 cups of liquid into the bucket)

- turn the pump on with the ball valve still closed

- Slowly open the ball valve and your pump (so you don't shock your HERMS coil) and it should be fully primed

You can see the wort pump riptide on the left in this photo (and my messy garage), and how I have it setup. This is an older photo and the pump on the right is my old chugger

TMK, terrific and timely response -- much appreciated! As an old ME, I find this to be a very eloquent solution to the priming problem (and also eliminates that messy potential spewing issue with the Riptide's bleed valve), and I also slap myself for not thinking of something similar. That's one of the things I love about this site.So on #1, I have installed an additional ball valve on the outlet of my wort Riptide which faces down toward the ground (a little different than Spike has it. When I prime it, I do the following:

On #2, I think 1 of 2 things is happening - either you have a bad valve (unlikely since it's a pretty simple mechanical device), or you are not accounting for the dead spot in the valve. They are very sensitive and I often times have to make TINY adjustments to them, but there is a large dead spot when they are fully closed and take between 1-2 full rotations before I get any flow at all. After that point, I only make very small adjustments.

- Start with the pump off

- put a bucket under it

- open the ball valve all the way,

- open the linear valve all the way

- and then open the kettle outlet to allow water/wort to flow through the line and pump out into the bucket

- As soon as you have a full line with no air bubbles, close the ball valve (I usually lose about 1-2 cups of liquid into the bucket)

- turn the pump on with the ball valve still closed

- Slowly open the ball valve and your pump (so you don't shock your HERMS coil) and it should be fully primed

You can see the wort pump riptide on the left in this photo (and my messy garage), and how I have it setup. This is an older photo and the pump on the right is my old chugger

View attachment 682401

If I am seeing this pic correct, you have the ball valve placed in-line on your wort pump's discharge line, but teed-off on the HLT pump. I would think the latter would provide more flexibility and ease in switching over from priming to pumping.

As to #2, I understand about the dead spot near the closed position of the valve, but sometimes I experience a big "lag" even away from this point. Agree that this valve can be just a sensitive beast at times.

If I may make a suggestion, I note that the line coming off the bottom of your HERMS coil is a bit kinked as it drops straight down to the pump. Of course this opens up when fluid is moving, but I have found that by using a QD with a 90 bend largely resolves any problems with potential hose restrictions. I've got them on all my hoses that have to make a sharp turn. Bobby carries them. Cheers

TMK, terrific and timely response -- much appreciated! As an old ME, I find this to be a very eloquent solution to the priming problem (and also eliminates that messy potential spewing issue with the Riptide's bleed valve), and I also slap myself for not thinking of something similar. That's one of the things I love about this site.

If I am seeing this pic correct, you have the ball valve placed in-line on your wort pump's discharge line, but teed-off on the HLT pump. I would think the latter would provide more flexibility and ease in switching over from priming to pumping.

As to #2, I understand about the dead spot near the closed position of the valve, but sometimes I experience a big "lag" even away from this point. Agree that this valve can be just a sensitive beast at times.

If I may make a suggestion, I note that the line coming off the bottom of your HERMS coil is a bit kinked as it drops straight down to the pump. Of course this opens up when fluid is moving, but I have found that by using a QD with a 90 bend largely resolves any problems with potential hose restrictions. I've got them on all my hoses that have to make a sharp turn. Bobby carries them. Cheers

View attachment 682406

Glad #1 was helpful! I forgot to add - hook up your hose after you close your ball valve and before you turn the pump on. I'm sure that was obvious but I realized I missed a step in there.

I played with the system with just water for awhile and saw pretty linear control with the valve, so I think what you're seeing must be caused by suction/compression of the grain bed then. I have noticed that my flow-rate will initially bog down due to the gain bed compacting a little, and I'll slowly compensate for that until it seems to level off - then I'll check on it about 30 minutes later and the flow is much higher than I left it, so I suspect that it's either from the proteins in the malt breaking up significantly, or because I'm getting some channelling. I have always stopped the pump, stirred the mash, and restarted circulation after this happens because I don't want to risk the loss of efficiency.

I actuall bought several of those after taking that photo! They have been great at eliminating kinks so thanks!

Thanks again, TMK. I almost always learn things when I look at people's rigs. I note that you have a 4" or 6" spool off the top port of your MT. What do you use this for? Also, I note that you have your valve located "kettle-side" of the instrument tee on the MT, but outside of the tee on the HLT. Do you have some operational reasons for this set up?Glad #1 was helpful! I forgot to add - hook up your hose after you close your ball valve and before you turn the pump on. I'm sure that was obvious but I realized I missed a step in there.

I played with the system with just water for awhile and saw pretty linear control with the valve, so I think what you're seeing must be caused by suction/compression of the grain bed then. I have noticed that my flow-rate will initially bog down due to the gain bed compacting a little, and I'll slowly compensate for that until it seems to level off - then I'll check on it about 30 minutes later and the flow is much higher than I left it, so I suspect that it's either from the proteins in the malt breaking up significantly, or because I'm getting some channelling. I have always stopped the pump, stirred the mash, and restarted circulation after this happens because I don't want to risk the loss of efficiency.

I actuall bought several of those after taking that photo! They have been great at eliminating kinks so thanks!

As I commented on this (or another) Spike discussion, I found I can make my system a little more idiot-proof (which I need as much as possible) to remove the top HERMS valve on the HLT and the valve on the top MT port. The reason for this is that if either of these valve are closed PLUS the lower HERMS valve, and you heat up the HLT, then any liquid which may be inside the HERMS coil will also heat up, and then you are at great risk for pushing out the HERMS coil from one of its friction fittings due to thermal expansion of the HERMS-trapped fluid. (I learned this the hard way in the middle of a brew...). I've found that I don't really need those top two valves for anything significant anyway.

Thanks again, TMK. I almost always learn things when I look at people's rigs. I note that you have a 4" or 6" spool off the top port of your MT. What do you use this for? Also, I note that you have your valve located "kettle-side" of the instrument tee on the MT, but outside of the tee on the HLT. Do you have some operational reasons for this set up?

As I commented on this (or another) Spike discussion, I found I can make my system a little more idiot-proof (which I need as much as possible) to remove the top HERMS valve on the HLT and the valve on the top MT port. The reason for this is that if either of these valve are closed PLUS the lower HERMS valve, and you heat up the HLT, then any liquid which may be inside the HERMS coil will also heat up, and then you are at great risk for pushing out the HERMS coil from one of its friction fittings due to thermal expansion of the HERMS-trapped fluid. (I learned this the hard way in the middle of a brew...). I've found that I don't really need those top two valves for anything significant anyway.

That spool on the top port of my MT is an additional instrument tee so that I'm measuring Mash tun out and mash tun in (rather than HERMS out, which should be the same as HLT bulk temp).

I don't have any reason why the valve is kettle side rather than the other side of the tee, and actually had never noticed that it was different, lol!

I like your idea of removing those valves. I have gotten to the point where opening and closing valves is mostly muscle memory, but I have definitely forgotten to open the MT return a couple times and wondered why I wasn't getting flow

Similar threads

- Replies

- 4

- Views

- 590

- Replies

- 6

- Views

- 2K

- Replies

- 7

- Views

- 673