Do you have any more details on how this is built? What's it made out of?

Yes, I have more details. It is pretty basic, really. Made it so that if anything failed I could easily replace it. I am sure others would be able to improve drastically.

it is made form some pieces of 1/4" thick aluminum (available from onlinemetals.com)- a 5"x5"x5" tube and a 3"x4"x8" tube, and a few plates as covers and internal elements.

PID is an Auber-instruments PID, as well as a second auber instruments pid that could reasonably be skipped.

Pump is a Rule il200p pump, and the element is just a standard camco 1500 watt water heater (ultra low density) element. I use an Auber rtd temperature probe and the electrical cord for the pump is run through a Brewer's Hardware 1/4" bored through compression fitting with 3 silicone o-rings instead of the metal parts. Below is the diagram of construction. Honestly, the hardest part, I thought, was getting al of the drill holes to line up, but I am VERY inexperienced with any kind of manufacturing or metal work.

Here is the basic layout of what is going on inside. Since making this, I externalized the fan, as I found it was very difficult to replace without taking the whole thing apart. If it is externalized, all I have to do is take the top off and the fan off:

Here is the electrical plan. Yes, this is a VERY primitive version of an electrical plan. I am not P-J and am by no means an electricial. The nice thing about the whole thing being all metal is that it is entirely grounded all the way from the water to the outlet, and it MUST be on a GFCI plug or else I would worry a lot more. I had thought about putting in a leak sensor in the lower tube, but after running it for many many hours at a time, I have never found even the slightest leak.

Is that enough detail for you Aubiecat?

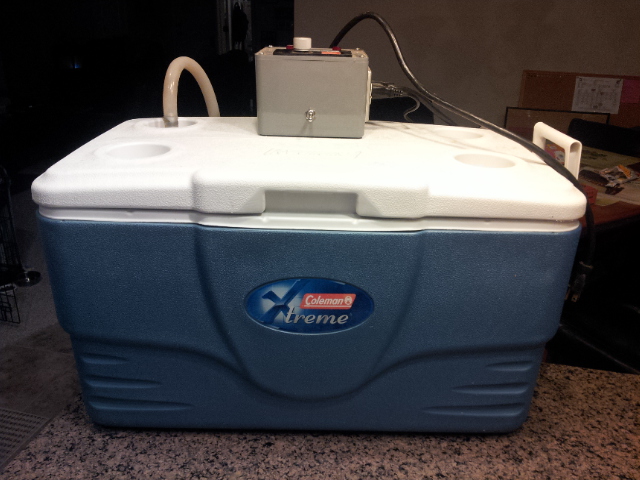

I had originally build a sous vide machine like the one in Seattlefoodgeek.com, but ultimately was not completely satisfied. This version uses many of the same components, but is just a bit more robust and sturdy. It does cost a bit more, mainly in the price of metal and the pump, which is 40 bucks instead of 12. This certainly didn't go over 200 dollars to build, but it takes a LOT of sweat equity. I had to learn from scratch how to work with metals.

If you notice, you could attach a filter screen (would have to make it a larger surface area than just 3x4" do it wouldn't get clogged) to the bottom and dip it in a large mash tun and you have a portable RIMS system for any container you might have.

Klaus

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)