cantrell00

Well-Known Member

- Joined

- Jul 6, 2013

- Messages

- 840

- Reaction score

- 116

The key there is the drill press.

This will test how good my soldering skills are with my fermentation vessel triclover setup.

You obviously know very little about drilling SS, especially thick SS. Its one thing to drill a hole in thin vessels, another totally different thing to tackle those caps.To drill holes in stainless you will need to go to the hardware store and find a drillbit. Preferably one that says its for metal.

You have two options putting a large triclover fitting on a keg lid.Low speed is a priority and a bit of lubrication can't hurt. And if you are wondering if you should drill the hole according to the inside diameter or the outside diameter of a fitting, well that one should explain itself. It'll be kinda hard to fit a pipe through a hole that's only as large as the hole in the pipe.

No, you cannot. It will have to be bimetal at the very least. Some come carbide tipped. Thus my question.Yes you can use a standard hole saw.

By punch I assume you mean a punch and die. How practical do you think it would be to buy a punch and die for a 4" Triclover fitting ? Not very.Yes it's faster and easier to use a punch but you still have to drill a hole to use a punch.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Bobby @ brewhardware.com sales a sanke fermenter conversion kit that would eliminate having to do all of this yourself..

Very reasonably priced I might add. $34.00

https://www.brewhardware.com/product_p/sankefermenterkit.htm

I would remove the spud and solder the nipple with two nuts in place. A spud does not permit an interior connection.

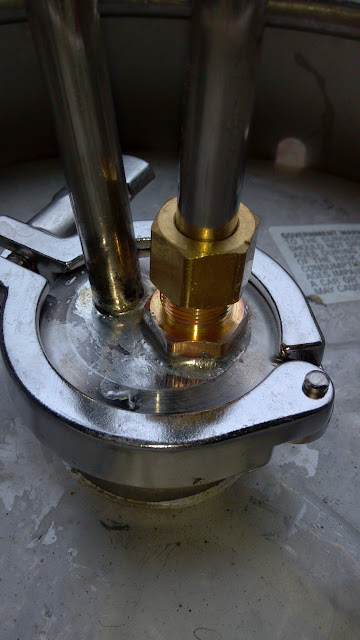

After thinking about it for a few days I had to suck it up and realize you are/were right. I reused the lock nut and the stainless close nipple and soldered in place. Works awesome and now I don't have those annoying shortcomings of the weldless bulkheads - rotating the entire fitting while trying to tighten one side, cutting the gasket and creating a leak at the most inopportune times.

Another ugly but strong and leakfree job! Love this soldering solution.

And a pic of my updated HLT thanks to Bobby's gear.

It is not beautiful but looks very solid. I get some pock marks in my seams that eventually leak slightly. I have seen the same thing in most pictures posted. It must be technique. What did you do to get yours looking so solid?

If you're getting leaks and pock marks you need to sand and clean more thoroughly.

It is not beautiful but looks very solid. I get some pock marks in my seams that eventually leak slightly. I have seen the same thing in most pictures posted. It must be technique. What did you do to get yours looking so solid?

Butt joined a Camlock A and Sanke D coupling nut together.

EDIT - I did this to be able to use a pump to clean and transfer from keg to keg.

I drilled out two sanke couplings for higher flow and use a sump pump to clean / sanitize and a magnetic pump or co2 pressure to rack from keg to keg.

Is there a nipple under that connection? Or is it just solder?

The last one I did did the same thing. I just used a hammer & chisel to tap the split as tight as I could get it to the coupling. Then I used a little plumber's putty to seal around the dimple, and the solder did the rest. The putty got a little smokey as I was soldering, but it stayed in place long enough to let the solder harden. Once it cooled, cleaned up with some BKF, and its like it never happened!

If you are splitting the stainless, I would guess the diameter of what you are drawing into is too small, or your hole is too small to begin with....by the time your done, you'll have it figured out