cantrell00

Well-Known Member

- Joined

- Jul 6, 2013

- Messages

- 840

- Reaction score

- 116

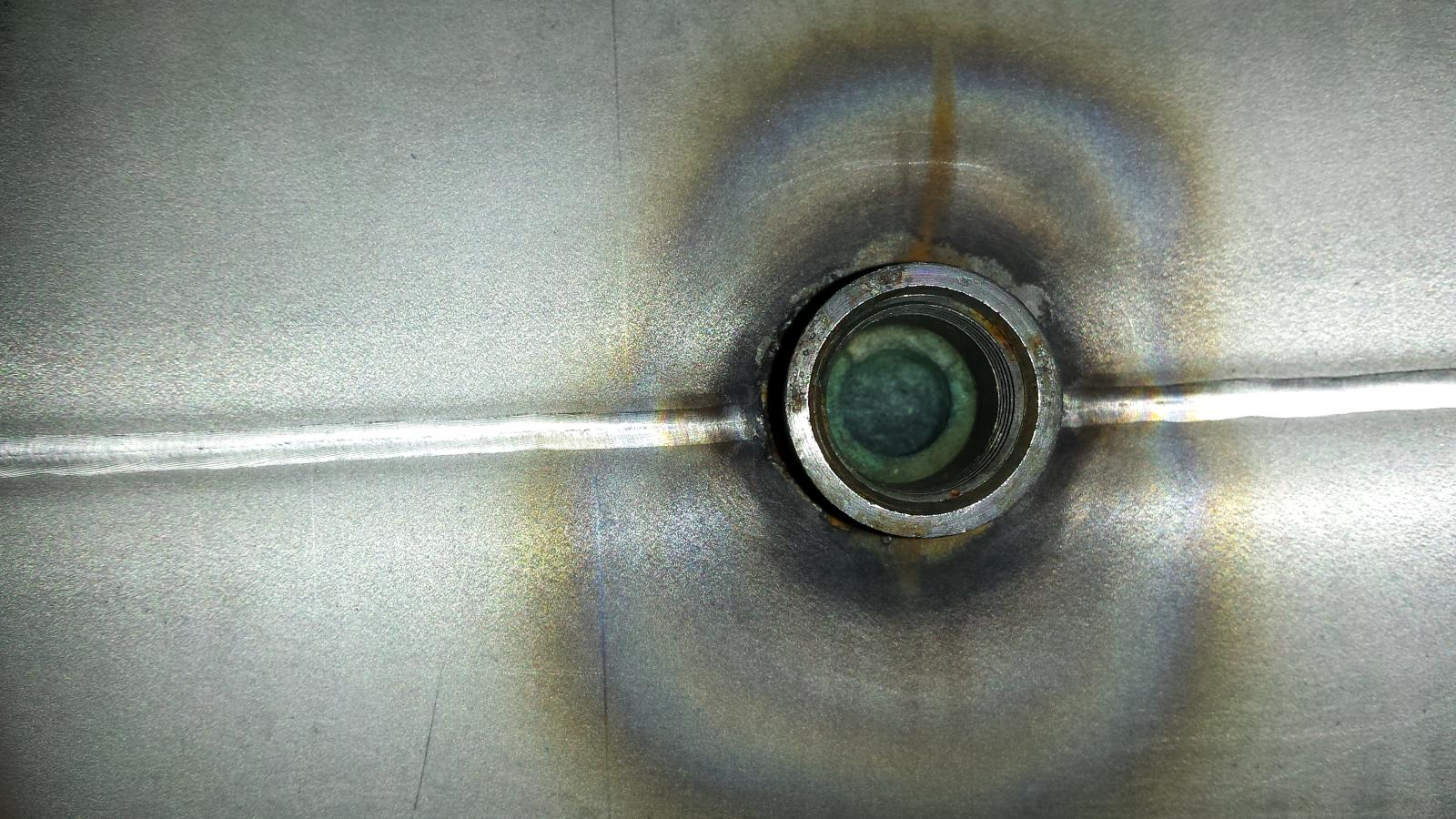

So bought a keggle off craiglist. Fittings have already been installed and welded on the outside. Unfortunately the work inside was not as good in fact although the don't leak I was wondering if I soldered in the inside by heading the fitting could I effect the weld on the front?

Sorry if this is a dumb question.

That solder will melt LONG before you get enough heat on the stainless welds to damage them...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)