BrokenDog

Well-Known Member

Hey guys I'm ordering all my parts to get my single tier together and all I have left is the gas parts, but I want to make sure I'm getting what I need.

I ordered the BG-14 burners and plan on using the orfices that came with it unless someone has another idea.

http://www.bayouclassicdepot.com/bg14_cast_iron_burner.htm

I'm looking at 2 different 30 psi regulators, I'll probably go with the Bayou just b/c that's where I plan to get the valves.

http://www.bayouclassicdepot.com/5hpr30-high-pressure-propane-regulator-kit.htm

http://www.midwestsupplies.com/regulator-kit-for-banjo-burner.html

The 2 needle valves I'm looking at are both from Bayou Classic, they look the same with the same stats but one is $3 cheaper and I can't figure out why if anyone has an idea.

http://www.bayouclassicdepot.com/638-fnpt-mpt-needle-valve-brass-fitting.htm

http://www.bayouclassicdepot.com/nv108p_propane_burner_part.htm

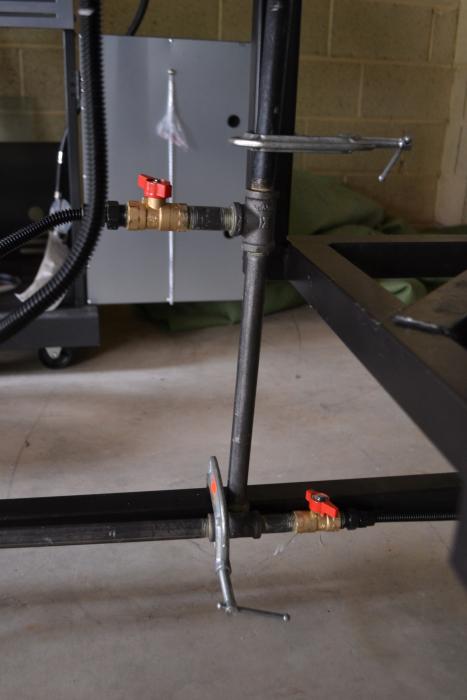

For plumbing I'll probably have some flexable hoses made to run between the burners like a lot of the BrewSteel models have, although black pipe is always an option.

Hopefully I can get some direction from someone who has experienced this issue since hours of searching don't seem to quite give me a solid answer.

I ordered the BG-14 burners and plan on using the orfices that came with it unless someone has another idea.

http://www.bayouclassicdepot.com/bg14_cast_iron_burner.htm

I'm looking at 2 different 30 psi regulators, I'll probably go with the Bayou just b/c that's where I plan to get the valves.

http://www.bayouclassicdepot.com/5hpr30-high-pressure-propane-regulator-kit.htm

http://www.midwestsupplies.com/regulator-kit-for-banjo-burner.html

The 2 needle valves I'm looking at are both from Bayou Classic, they look the same with the same stats but one is $3 cheaper and I can't figure out why if anyone has an idea.

http://www.bayouclassicdepot.com/638-fnpt-mpt-needle-valve-brass-fitting.htm

http://www.bayouclassicdepot.com/nv108p_propane_burner_part.htm

For plumbing I'll probably have some flexable hoses made to run between the burners like a lot of the BrewSteel models have, although black pipe is always an option.

Hopefully I can get some direction from someone who has experienced this issue since hours of searching don't seem to quite give me a solid answer.