bluedog_Brewing

Well-Known Member

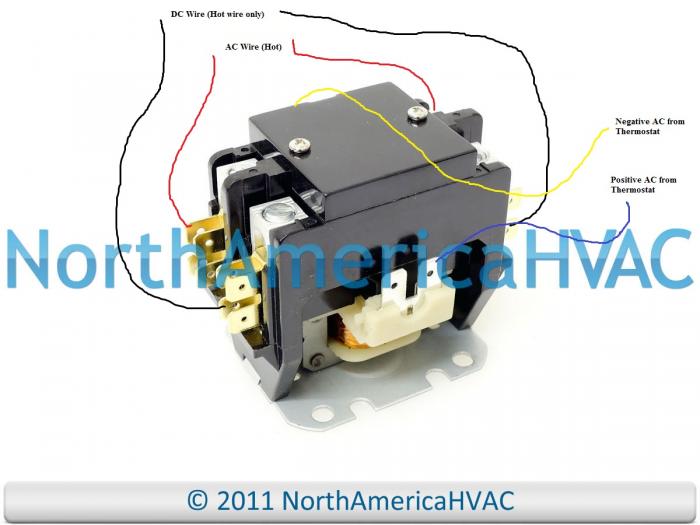

I am using (2) 120VAC STC-1000s. I spliced into the line the feeds the fridge side interior light (before the door switch so that it is always on) and us that to power both thermostats, the (2) 120V fans and the (2) relays.

I cut the black wire from the circuit board to the compressor and the yellow wire from the circuit board to the condensor fan. I routed these to the 2-pole relay and then back to the device side of the wires I cut. So now the relay just reconnects the original wires whenever the thermostat needs to cool the freezer side. I cut the yellow wire (speed control signal I think) to the condensor instead of the red (+13V power supply) because I wanted to leave the evaporator fan running all the time to keep the temps in the freezer side even. If you do not want to run the evap fan all the time, cut the red wire instead of the yellow.

The fridge side thermostat is powered off the same wires as the freezer side (120V line that feeds the interior light switch) and I just used a short jumper wire to supply power to the cooling relay outputs which run the fans. I used (2) 120mm, 120VAC fans. One is at the bottom of the divider and pushed air from the fridge into the freezer. The second is at the top of the divider and pushes air from the freezer into the fridge.

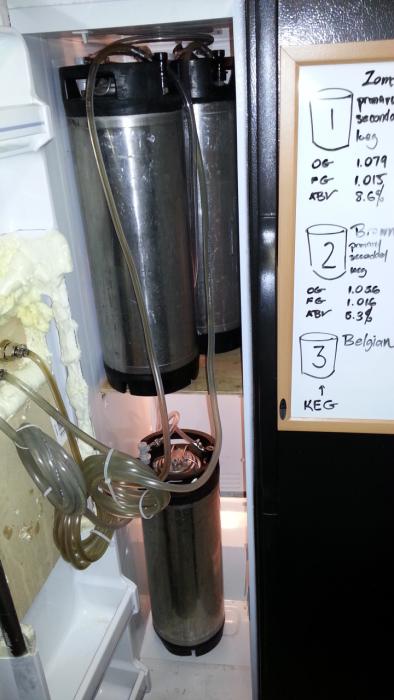

I have been very pleased with my setup so far. It was my first kegerator and I have been very happy to stop bottling!

Good luck and let me know if you have any other questions.

I cut the black wire from the circuit board to the compressor and the yellow wire from the circuit board to the condensor fan. I routed these to the 2-pole relay and then back to the device side of the wires I cut. So now the relay just reconnects the original wires whenever the thermostat needs to cool the freezer side. I cut the yellow wire (speed control signal I think) to the condensor instead of the red (+13V power supply) because I wanted to leave the evaporator fan running all the time to keep the temps in the freezer side even. If you do not want to run the evap fan all the time, cut the red wire instead of the yellow.

The fridge side thermostat is powered off the same wires as the freezer side (120V line that feeds the interior light switch) and I just used a short jumper wire to supply power to the cooling relay outputs which run the fans. I used (2) 120mm, 120VAC fans. One is at the bottom of the divider and pushed air from the fridge into the freezer. The second is at the top of the divider and pushes air from the freezer into the fridge.

I have been very pleased with my setup so far. It was my first kegerator and I have been very happy to stop bottling!

Good luck and let me know if you have any other questions.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)