Brewer_opie

Member

- Joined

- Aug 16, 2008

- Messages

- 14

- Reaction score

- 0

I'd use 18 gauge. The 14 gulags was hard to tie in. I'm almost done with my rig (at least the temp control side... Will run keg lines soon), and will post pictures.

Any idea if there are cooling coils in the middle section? Imagine how many kegs you could fit in there if the middle was open. Or like a 2bbl conical.

I get a 22 degree spread right now. But I have no damper. I just put in a louver system... I'm hoping that keep the fridge side warmer. I'll add a heating element soon, but want to keep the heating to a minimum. I hate the idea of fighting the cold to get heat.

That relay will work fine. It's way oversized but I am using almost exactly the same thing.

Relays aren't hard to work with, just think of it as a switch that is turned on and off with electricity.

Lastly, I cut removed the OEM damper and enlarged the hole with a dremel cut-off wheel to fit one of the the 120mm fan. I made a similar cutout in the bottom of the divider where there was a manually adjustable damper and installed a second fan there. You could probably get by with one fan but I found that using two fans really helps me drop the temps quickly when I want to crash cool a batch.

You should definitely get the dryer duct dampers that I used (posted a pic of them previously). I originally set it up without them and there was too much cold air leaking into the fridge side to maintain fermentation temps.

I am using (2) 120VAC STC-1000s. I spliced into the line the feeds the fridge side interior light (before the door switch so that it is always on) and us that to power both thermostats, the (2) 120V fans and the (2) relays.

Randy,

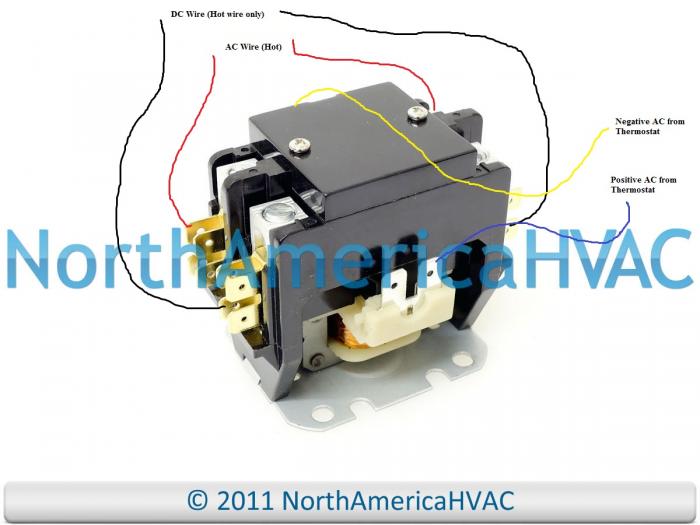

You only need one of the relays in the link you provided. That relay has two separate pairs of contacts, one can be used for the DC wire (condensor) and the other pair is used for the AC wire (compressor). I adding some wiring info to the ebay vendor photo you linked.

You do not need to switch the negative DC or neutral AC wires, so one of the 2 pole relays can switch two separate hot wires.

I hope that makes sense.

Sean

Randy,

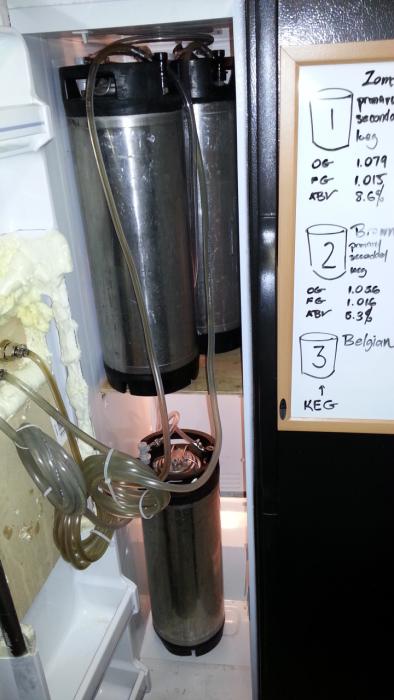

I found that my kegerator side would warm up fairly quicker so I tinkered with the setting till I was satisfied. I am using the following:

Freezer Side:

F1: 0.5, F2: 3.0, F3: 10, F4: 0

Fridge Side:

F1: 5.0, F2: 0.5, F3: 1, F4: 0

I set the freezer side cooler than I want the kegs and use a larger differential to reduce the frequency that the compressor cycles. I have been having good results with it so far.

Both these builds are really nice, an inspiration to say the least. I'm hunting for a SxS to do this to, much better solution than the complex chest freezer build I had been considering. I notice both these units are GE computerized models, these things have a mind of their own to run the automatic defrost cycle, has that been any problem?

Hello,

I have read several others taking on similar projects and had a few questions before I start. I am new to brewing and decided to jump in the deep end with this project. I am very excited to get going and begin brewing.

I recently came across an older Hot Point side by side as well that I am attempting to convert into a kegerator/ fermentation chamber. The model number is CSX22GR BG. I have contacted GE and they e-mailed a copy of the wiring diagram. I consider myself somewhat handy but am a novice as far as electrical work. I have read several threads on people taking on projects like this using the Love TSS2 Dual Temperature Control switch. Is this something that would be recommended with this unit as well? It seems that all of the cooling takes place on the freezer side and a fan moves the cool air to the fridge side. I am a novice so I may be wrong. I am basically trying to regulate the temperature on the freezer side to serving temp as this is where my corny kegs will be stored and regulate the fridge side temperature for fermenting ales. I do not think that I can do this with the factory switches/ thermostat. As you can tell I am a little lost and not sure where to begin.

I also read about a lot about the Digital STC-1000 All-Purpose Temperature Controller (cheaper but not sure if it is better). Also would it be necessary to install a different fan or can the factory fan be utilized to push air from the freezer side to the fridge side? I have seen several people install a 120 VAC PC fan

Any guidance will be greatly appreciated.

Sorry for such a long post with all of the questions. I have seen how helpful some of the veterans can be.

Thanks

No worries about the questions. Besides I only see two questions.

1. I don't have any experience with the Love 2-stage controller, but I think it basically combines the relay output from two STC-1000 controllers into one device. Since it costs more than double the price of the STC-1000, I just used two of those.

2. I am not sure how your fridge works, but most side by sides I have seen don't have a fan to move air, they use the evaporator fan located in the freezer and ducts that open and close to regulate the temperature of the fridge.

Take a look early in this thread and I provided more details on how I setup my fridge, along with some pictures. There are also several other side by side conversion threads out there.

Good luck with the build!