jfkriege

Well-Known Member

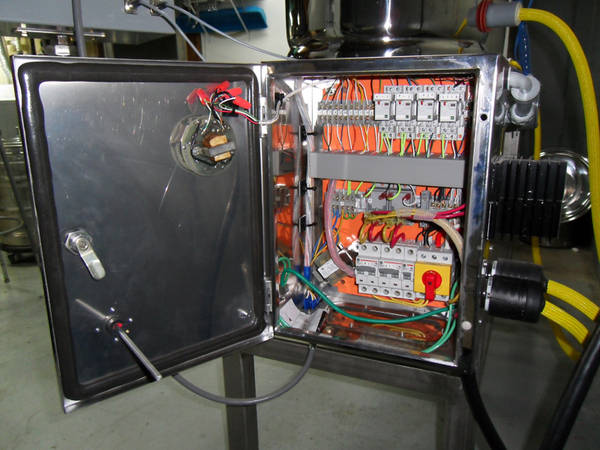

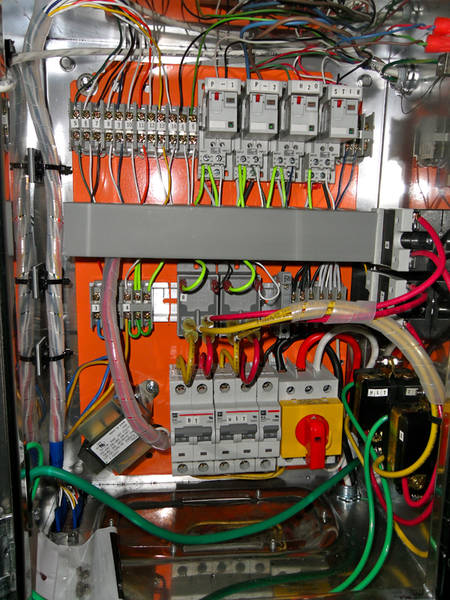

Two systems from a common control box. A 2.5 gallon system on the left and a 5/10 gallon system on the right. Pumps and some fittings are also shared. BK high to act as BK and RIMS when recirculation mashing.

I am currently cleaning them up and redoing the control box. I will post pics when I am done.

I am currently cleaning them up and redoing the control box. I will post pics when I am done.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)