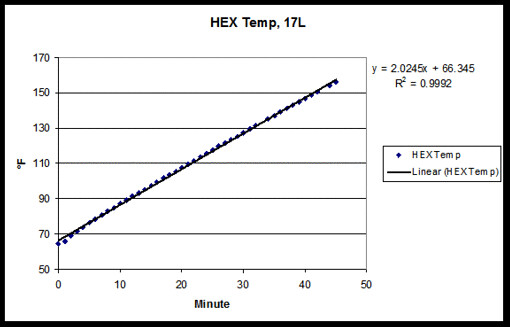

After having some time to try out the new HEX a few times, I thought I'd post some data. Here is how the HEX heats itself up with 17L (enough to cover the top of the coil) of water. Lesson learned, add hot tap water to jump start the process. With room temp at 64F, no stirring and no insulation I get 2F/min.

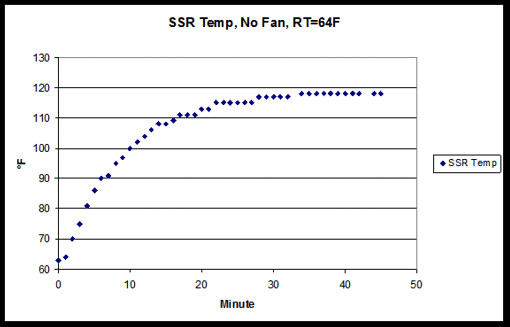

Right now I don't have the SSR heat sinc outside of the control box or have a fan on it so I wanted to know how hot the sinc would get. (and to not burn it up either) I put a probe underneath the SSR on the first fin of the sinc to monitor the temp rise. Under full, constant load of a 1500 watt element, temp flattened out at 119F.

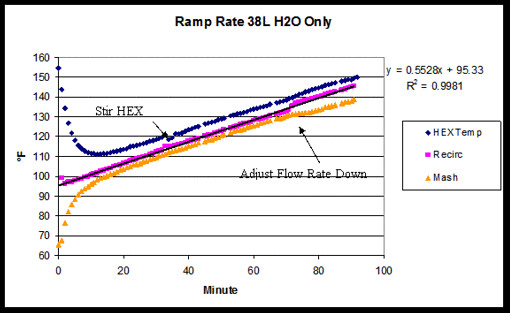

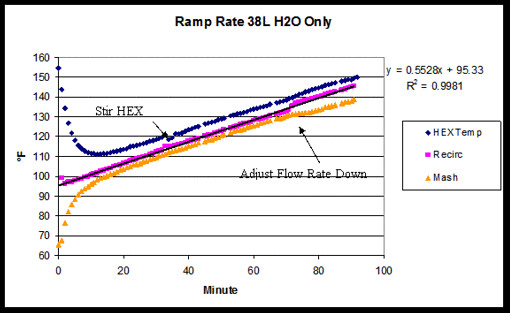

To somewhat simulate mash conditions, I put 38L of water in the MLT and tried to heat it up. The water in the HEX was at 155F and the MLT was at 64F, flow rate was 9.3L/min (faster than a mash and due to no grains, more mixing). As you can see there was a quick bump in mash temp and a quick drop in HEX temp. Lesson learned, heating strike water to temp this way will take a long time. You can also see that the HEX temp dropped and the Recirc temp jumped up when the chamber water was stirred. There was also more heat transfer when the ball valve was set to about 1/2 flow. Sorry I didn't actually measure the flow rate.

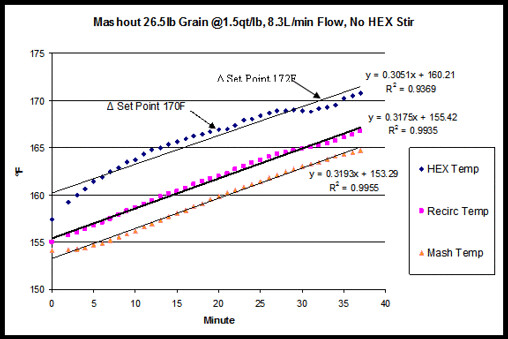

The latest test was on an actual mash-out with 26.5lb of grain at a 1.5qt/lb ratio. You can see the delay in application of heat, the mash temp is measured at the exit. Residence time is 4.1 minutes at a flow rate of 8.3L/min. A few things to note, I had the PID set point at 168F initially but as the HEX approached the SP, it started to back off heating. I adjusted it to 170F and then 172F. Lesson learned, keep the HEX SP about 8F hotter on ramps and Start to heat up before you start the mash-out/ramp. This will save about 10-15 minutes.

All in all, I think things worked out very well for maintaining mash temps with little to no effort. The ramp rate was about 0.32F/min without stirring. For the next brew, I'll start with the HEX at a higher temp and try to implement some chamber water mixing to see if the recirc temp and HEX temp can be closer.