Yep, that center bolt is almost exactly what I did as well. And yeah, my stock false bottom took a few beatings (especially before the bolt was added), but I have able to bend it back into good enough shape (so far).I’ve been experimenting with BIAB in my Brewzilla and after crushing my false bottom I added a screw to act as support. Works great! I was able to use a rubber mallet to flatten the crushed false bottom.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Robobrew/Brewzilla Discussion

- Thread starter rjhoff

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jan 28, 2013

- Messages

- 3,926

- Reaction score

- 3,026

I’ve been experimenting with BIAB in my Brewzilla and after crushing my false bottom I added a screw to act as support. Works great! I was able to use a rubber mallet to flatten the crushed false bottom.

What size screw is that?

M6, 40MM length, 304SSWhat size screw is that?

Update on my support bolt for the false bottom.M6, 40MM length, 304SS

First brew the support did the job but my brew yesterday it bent the false bottom a little. It's still doing a good job at keeping the bag away from the elements which is all I'm concerned about. For now I'll just keep bending it back as long as it doesn't get too bad.

trarmer007

Member

- Joined

- Sep 20, 2021

- Messages

- 13

- Reaction score

- 7

Checking back in. I am 1.5 years and about a dozen brews into a 65L, 3.1.1, 220v. My biggest frustration was auto-shut downs at boiling due to scorch grain-**** on the bottom. My second was the piss poor efficiency (65%). Fixing either was a catch-22. By grinding grain further to get better effic., I created more 'dust' to stick to the bottom and scorch. So I went back to mashing in my cooler - no more scorched mess on the bottom and efficiency is in the high 80's. The 65l is a hot liquor tank, then I fly sparge into pots. When I'm out of HLT water, wort is ready to pour in from pots. I hit boil in 10-15 minutes. Honestly, I am happy even though the malt pipe does not function enough. There's 1.7 gallons of dead tun space which limits the amount of sparge/rinse water which can be used. I've no idea how to improve the grain dust/scorching issue. Anyway - a cross German-CAP pilsner will be ready in a few months and the fruit-cream ale in a few weeks. The Belgian Strong on tap just may last until then...Cheers

cactusgarrett

Well-Known Member

My biggest frustration was auto-shut downs at boiling due to scorch grain-**** on the bottom. My second was the piss poor efficiency (65%).

I used to get 70-75% with a cooler/burner, but just assumed the efficiency hit going over to the exact unit you have (65L, 220V). I was getting 65% for the longest time, and a slight tightening of the mill gap brought it to 70% reliably. I'm good with that; to me it's more important to be reliable than a high percentage. With 65%, you just needs an extra pound of base grain to make up for it. I haven't had any issues with scorching, even with the 100% maris otter or hefe grists I've done recently. Are you recircing during the mash? This helps with wort clarity at boil start.

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

trarmer007

Member

- Joined

- Sep 20, 2021

- Messages

- 13

- Reaction score

- 7

I run the recirc pump from moment I start heating water to about 10 minutes into the boil (sanitize for pump into ferm.) I always circ'd over the grain bed. For whatever reason I had a heck of time with scorching. I brew at sea level - so boil is 212 and not a penny less. I keep 2, sometimes 3, burners hot during the boil. I got the jacket and it helped some. Even with the cooler as mashtun there is a snake line of slightly cooked **** tracking the heating coil lines. post-boil. Maybe my unit got a less than stellar steel coating at the bottom. Being only 18 months or so post keg, propane and cooler - I still think brew day is breeze with the unit. The pump alone saves me probably an hour of racking. The rapid mash out to - boil is another hour of my life. The cooler mash step is not much different than the mash pipe too.I used to get 70-75% with a cooler/burner, but just assumed the efficiency hit going over to the exact unit you have (65L, 220V). I was getting 65% for the longest time, and a slight tightening of the mill gap brought it to 70% reliably. I'm good with that; to me it's more important to be reliable than a high percentage. With 65%, you just needs an extra pound of base grain to make up for it. I haven't had any issues with scorching, even with the 100% maris otter or hefe grists I've done recently. Are you recircing during the mash? This helps with wort clarity at boil start.

Teufelhunde

Well-Known Member

- Joined

- Jan 4, 2020

- Messages

- 520

- Reaction score

- 479

I've been brewing on a 35l 3.1.1 for about a year now, and have always wondered what the temperature in the malt pipe was in relation to the set temperature on the controller. I have previously checked the calibration on my controller using plain water in the unit and two other thermometers I have and found it to be accurate.

I recently came across a meat thermometer with waterproof probes, and, as it was inexpensive, bought it. I enlarged one of the holes in my top screen to allow for the probe to be slid through it. In this mornings mash (temp set to 147 degrees), the temp in what should be close to the center of the grain bed started out at 144 at the beginning of the mash. It slowly climbed to 149 at about 40 minutes in, then retreated to 148 where it remained until done. This gives me a little confidence that the unit is maintaining my set temperature pretty well as I figure a 5 degree variance around the set temp is not bad.

I have also been dialing in my new Maltzilla mill, this was my third brew doing my own milling rather that buying milled grain from Morebeer. Last time, I had the crush too fine and my mash stuck big time. This time, I opened the gap a little and was able to maintain recirc for the whole mash, albeit VERY slow. When I drained it prior to boil, I saw the issue (attached photo). Two thirds of my top screen was covered with an eight inch of dough, not allowing flow. Next time, I'll open the gap another "click", and hopefully, it will allow for better flow through the top screen. I am wondering, however, how improved flow through the top screen will alter the temperature, if at all.

YMMV

Lon

I recently came across a meat thermometer with waterproof probes, and, as it was inexpensive, bought it. I enlarged one of the holes in my top screen to allow for the probe to be slid through it. In this mornings mash (temp set to 147 degrees), the temp in what should be close to the center of the grain bed started out at 144 at the beginning of the mash. It slowly climbed to 149 at about 40 minutes in, then retreated to 148 where it remained until done. This gives me a little confidence that the unit is maintaining my set temperature pretty well as I figure a 5 degree variance around the set temp is not bad.

I have also been dialing in my new Maltzilla mill, this was my third brew doing my own milling rather that buying milled grain from Morebeer. Last time, I had the crush too fine and my mash stuck big time. This time, I opened the gap a little and was able to maintain recirc for the whole mash, albeit VERY slow. When I drained it prior to boil, I saw the issue (attached photo). Two thirds of my top screen was covered with an eight inch of dough, not allowing flow. Next time, I'll open the gap another "click", and hopefully, it will allow for better flow through the top screen. I am wondering, however, how improved flow through the top screen will alter the temperature, if at all.

YMMV

Lon

Attachments

I had issues with temperature uniformity and stuck sparges too when I first got my Brewzilla. Once you get the flow up it stays pretty consistent, maybe closer to 2-3F realistically. There's a lot of talk about milling grain more and more fine but with these units it doesn't really equate to improved efficiency, just headaches.I've been brewing on a 35l 3.1.1 for about a year now, and have always wondered what the temperature in the malt pipe was in relation to the set temperature on the controller. I have previously checked the calibration on my controller using plain water in the unit and two other thermometers I have and found it to be accurate.

I recently came across a meat thermometer with waterproof probes, and, as it was inexpensive, bought it. I enlarged one of the holes in my top screen to allow for the probe to be slid through it. In this mornings mash (temp set to 147 degrees), the temp in what should be close to the center of the grain bed started out at 144 at the beginning of the mash. It slowly climbed to 149 at about 40 minutes in, then retreated to 148 where it remained until done. This gives me a little confidence that the unit is maintaining my set temperature pretty well as I figure a 5 degree variance around the set temp is not bad.

I have also been dialing in my new Maltzilla mill, this was my third brew doing my own milling rather that buying milled grain from Morebeer. Last time, I had the crush too fine and my mash stuck big time. This time, I opened the gap a little and was able to maintain recirc for the whole mash, albeit VERY slow. When I drained it prior to boil, I saw the issue (attached photo). Two thirds of my top screen was covered with an eight inch of dough, not allowing flow. Next time, I'll open the gap another "click", and hopefully, it will allow for better flow through the top screen. I am wondering, however, how improved flow through the top screen will alter the temperature, if at all.

YMMV

Lon

Grain conditioning is another step I've been sticking with as I've found it reduces fine particles in my crush.

Teufelhunde

Well-Known Member

- Joined

- Jan 4, 2020

- Messages

- 520

- Reaction score

- 479

Yep. Don't really measure them though, just throw a couple of handfuls in every time after I stop pouring grain in to stir it up a bit. This batch had probably a quarter to a third of a pound....Are you using any rice hulls?

Teufelhunde

Well-Known Member

- Joined

- Jan 4, 2020

- Messages

- 520

- Reaction score

- 479

Yep, this brew was at 74%. I would gladly go down to 70% or even 65% as long as it was consistent and I could get a good flow for recirculation. I'll just keep opening up the gap one click at a time until I get there.....I had issues with temperature uniformity and stuck sparges too when I first got my Brewzilla. Once you get the flow up it stays pretty consistent, maybe closer to 2-3F realistically. There's a lot of talk about milling grain more and more fine but with these units it doesn't really equate to improved efficiency, just headaches.

Grain conditioning is another step I've been sticking with as I've found it reduces fine particles in my crush.

- Joined

- Jun 9, 2022

- Messages

- 35

- Reaction score

- 24

I was able to recover over a gallon of dead mash space by removing the bottom plate and the support ring, and installing legs on the mash pipe brackets. The mash pipe sits about 1-1/4 inches from the bottom now. I use a block and tackle to slowly raise the pipe while sparging. I try to keep the bottom of the pipe submerged to control HSA. I put the bottom plate in for the last 5 minutes of the boil. I find there's less scorching and a more even boil without it.

DuncB

Well-Known Member

Never thought that I'd come across another Maltzilla user. I've been using mine a few years now and don't have problems with stuck mashes or sparges. Stuck sparge on an imperial stout where I milled the rye to the perfect size that filled every hole in the bottom of the malt pipe.I've been brewing on a 35l 3.1.1 for about a year now, and have always wondered what the temperature in the malt pipe was in relation to the set temperature on the controller. I have previously checked the calibration on my controller using plain water in the unit and two other thermometers I have and found it to be accurate.

I recently came across a meat thermometer with waterproof probes, and, as it was inexpensive, bought it. I enlarged one of the holes in my top screen to allow for the probe to be slid through it. In this mornings mash (temp set to 147 degrees), the temp in what should be close to the center of the grain bed started out at 144 at the beginning of the mash. It slowly climbed to 149 at about 40 minutes in, then retreated to 148 where it remained until done. This gives me a little confidence that the unit is maintaining my set temperature pretty well as I figure a 5 degree variance around the set temp is not bad.

I have also been dialing in my new Maltzilla mill, this was my third brew doing my own milling rather that buying milled grain from Morebeer. Last time, I had the crush too fine and my mash stuck big time. This time, I opened the gap a little and was able to maintain recirc for the whole mash, albeit VERY slow. When I drained it prior to boil, I saw the issue (attached photo). Two thirds of my top screen was covered with an eight inch of dough, not allowing flow. Next time, I'll open the gap another "click", and hopefully, it will allow for better flow through the top screen. I am wondering, however, how improved flow through the top screen will alter the temperature, if at all.

YMMV

Lon

I do condition the grain with 2% by weight of water sprayed onto the grain and mixed during this process, leave for about 20 minutes to an hour before milling. Can't remember the gap I have set but it's pretty tight. I'd say that I struggle to keep liquid above the grain once the mash gets going. Efficiency of mash now 90%, brewhouse varies depending on hop load and other factors.

I haven't used that bottom screen in my brewzilla or the guten 70 for ages and just put the trubtrapper in. Haven't had problems with the scorched bottom either.

When I'm home I'll let you know the gap I'm using.

I did get trouble with a gummed up bearing on the freewheeling roller, Kegland said that I should be vacuuming or air blasting it out!

Teufelhunde

Well-Known Member

- Joined

- Jan 4, 2020

- Messages

- 520

- Reaction score

- 479

Never thought that I'd come across another Maltzilla user. I've been using mine a few years now and don't have problems with stuck mashes or sparges. Stuck sparge on an imperial stout where I milled the rye to the perfect size that filled every hole in the bottom of the malt pipe.

I do condition the grain with 2% by weight of water sprayed onto the grain and mixed during this process, leave for about 20 minutes to an hour before milling. Can't remember the gap I have set but it's pretty tight. I'd say that I struggle to keep liquid above the grain once the mash gets going. Efficiency of mash now 90%, brewhouse varies depending on hop load and other factors.

I haven't used that bottom screen in my brewzilla or the guten 70 for ages and just put the trubtrapper in. Haven't had problems with the scorched bottom either.

When I'm home I'll let you know the gap I'm using.

I did get trouble with a gummed up bearing on the freewheeling roller, Kegland said that I should be vacuuming or air blasting it out!

I'd appreciate knowing your gap setting. I have been air blasting mine everytime when I'm done with it, mostly because I mill on the back porch and don't want to bring all that dust in the house when I bring everything in....

DuncB

Well-Known Member

Another 24 hours before I'm home. Will update.I'd appreciate knowing your gap setting. I have been air blasting mine everytime when I'm done with it, mostly because I mill on the back porch and don't want to bring all that dust in the house when I bring everything in....

I'll update you with some pictures here or ? start a Maltzilla thread.

cactusgarrett

Well-Known Member

Two key points that everyone should note. I found milling finer has only netted me +5%, up to 70%. However, I needed to religiously condition the grain prior to milling, which I'm 100% fine with. That and rice hulls for every batch, regardless of grist composition.There's a lot of talk about milling grain more and more fine but with these units it doesn't really equate to improved efficiency, just headaches.

Grain conditioning is another step I've been sticking with as I've found it reduces fine particles in my crush.

Teufelhunde

Well-Known Member

- Joined

- Jan 4, 2020

- Messages

- 520

- Reaction score

- 479

Not sure if there are enough Maltzilla users to warrant it's own thread.....although it is a bit off topic here.....Another 24 hours before I'm home. Will update.

I'll update you with some pictures here or ? start a Maltzilla thread.

- Joined

- Jun 9, 2022

- Messages

- 35

- Reaction score

- 24

Correct. I only use the malt pipe false bottom for the mash. I slide the kettle false bottom in only for the last 5 minutes of the boil to catch trub during cooling. I was having problems with scorching and surging boils before I did that. I found that the kettle false bottom has a tendency to trap steam which causes surges.@maltboy1 - So you don't use the separate bottom screen during the mash and instead just use the screen on the bottom of the malt pipe only?

private4587

Active Member

- Joined

- Sep 23, 2016

- Messages

- 35

- Reaction score

- 0

could you explain please how you worked out your water volumes for the various steps@Bottoms_Up - If you sparge, you will get decent efficiency. But I also try to stay under 12-13 lbs of malt in the 35L. If there is more than that, I split it up and do a reiterated mash.

could you explain please how you worked out your water volumes for the various steps

I'm not sure I understand your question correctly, but I think the answer is "I wing it." (Or more accurately "eyeball it."). I don't do volume calculations. I usually aim for 7 gallon batches but am flexible about final volume (and gravity). I usually mash initially roughly in 6-7 gallons, sparge with 2 more gallons. If my volume is too low after sparge, I sparge a bit more. Mash again (with less grains the second time), and sparge to desired total volume. Add the extender before the boil.

I am flexible with volume because I usually do a pseudo partigyle and also take 1-2 gallons of wort at some point to use in a separate extra beer/recipe.

Here is an article that discusses the reiterated mash in more detail, but it doesn't give a specific way to calculate volume either. https://grainfather.com/reiterated-mashing/

Last edited:

CUSTOM-441

Robobrew v3.1 35L

Checking back in!

Brewed a double batch of my annual rye ale yesterday using 100% maple sap as my brew water. Sap was 1.010 on it's own. Flaked & malted rye were ~21% of the grain bill. As an experiment I skipped the beta glucan rest this time and went straight to a single infusion mash. I used nearly 5oz of rice hulls and bumped my water/grist ratio. Absolutely no issues with mash or sparge on both batches. I have not changed my process in about a year and I vary between 70-75% efficiency.

Brewed a double batch of my annual rye ale yesterday using 100% maple sap as my brew water. Sap was 1.010 on it's own. Flaked & malted rye were ~21% of the grain bill. As an experiment I skipped the beta glucan rest this time and went straight to a single infusion mash. I used nearly 5oz of rice hulls and bumped my water/grist ratio. Absolutely no issues with mash or sparge on both batches. I have not changed my process in about a year and I vary between 70-75% efficiency.

How does that line up with the drain? I assume just off center?I’ve been experimenting with BIAB in my Brewzilla and after crushing my false bottom I added a screw to act as support. Works great! I was able to use a rubber mallet to flatten the crushed false bottom.

DuncB

Well-Known Member

This is the before 4 thread so the drain is on the side of the kettle and no crying about bad temperature control, stuck mashes etc.How does that line up with the drain? I assume just off center?

For the Gen 3, the drain is off to the side so the screw in the center clears it no problem.How does that line up with the drain? I assume just off center?

Yeah, sounds like a lot of Gen 4 issues are coming up. I can't tell if there are more issues than the Gen 3, or just more people discovering more of the same types of problems.This is the before 4 thread so the drain is on the side of the kettle and no crying about bad temperature control, stuck mashes etc.

I'm glad to see KegLand has commented directly in that thread (as it has for awhile on the Australian homebrew site). But I wonder if they now regret doing so. Posters on this site seem a bit less laid back than the Australian forum with their comments.

ShaneB

Well-Known Member

Hey I'm new to homebrewing,

I have a 220v (split phase us power) digimash coming in the mail and I'm interested in retrofitting my own Arduino or ESP32 like microcontroller to do PID temperature control. I'm hoping I can get better temperature precision and it's just fun to tinker with things. Craftbeerpi looks like it can do this stuff.

I found a few resources online:

Digiboil hacks

retrofit kit Store – SmartPID

Has anyone done this with a digiboil/digimash? The split phase (2 hot, 1 ground) complicates things in my head. I'm pretty sure I can use a normal 110-220v ac/dc powersupply to get 5v and hook up hot1 and hot2 to hot and neutral on the ac/dc powersupply. I'm a bit confused on the SSR setup, would I just hook up 1 hot to the SSR and treat the other one as neutral? Then each half phase the SSR is alternating between switching hot and neutral?

Maybe a contactor is more appropriate? What about using 2 SSR, 1 for each half phase, that would also help distribute heat.

I have a 220v (split phase us power) digimash coming in the mail and I'm interested in retrofitting my own Arduino or ESP32 like microcontroller to do PID temperature control. I'm hoping I can get better temperature precision and it's just fun to tinker with things. Craftbeerpi looks like it can do this stuff.

I found a few resources online:

Digiboil hacks

retrofit kit Store – SmartPID

Has anyone done this with a digiboil/digimash? The split phase (2 hot, 1 ground) complicates things in my head. I'm pretty sure I can use a normal 110-220v ac/dc powersupply to get 5v and hook up hot1 and hot2 to hot and neutral on the ac/dc powersupply. I'm a bit confused on the SSR setup, would I just hook up 1 hot to the SSR and treat the other one as neutral? Then each half phase the SSR is alternating between switching hot and neutral?

Maybe a contactor is more appropriate? What about using 2 SSR, 1 for each half phase, that would also help distribute heat.

Last edited:

DuncB

Well-Known Member

Hey I'm new to homebrewing,

I have a 220v (split phase us power) digimash coming in the mail and I'm interested in retrofitting my own Arduino or ESP32 like microcontroller to do PID temperature control. I'm hoping I can get better temperature precision and it's just fun to tinker with things. Craftbeerpi looks like it can do this stuff.

I found a few resources online:

Digiboil hacks

retrofit kit Store – SmartPID

Has anyone done this with a digiboil/digimash? The split phase (2 hot, 1 ground) complicates things in my head. I'm pretty sure I can use a normal 110-220v ac/dc powersupply to get 5v and hook up hot1 and hot2 to hot and neutral on the ac/dc powersupply. I'm a bit confused on the SSR setup, would I just hook up 1 hot to the SSR and treat the other one as neutral? Then each half phase the SSR is alternating between switching hot and neutral?

Maybe a contactor is more appropriate? What about using 2 SSR, 1 for each half phase, that would also help distribute heat.

I've fitted a smartpid to my guten, have helped another user fit the smartpid to their digiboil and added pump. Have a look at smartpid.com

I used my 3.1.1 to brew today, still refining my process. I did notice that at a simmer it only read 206, and at a boil 208. I'm only about 130' above sea level, not enough to make a difference. Which makes me think my unit needs calibration. But when draining after cleaning, the water coming out tested almost exactly at the reading. Suggestions?

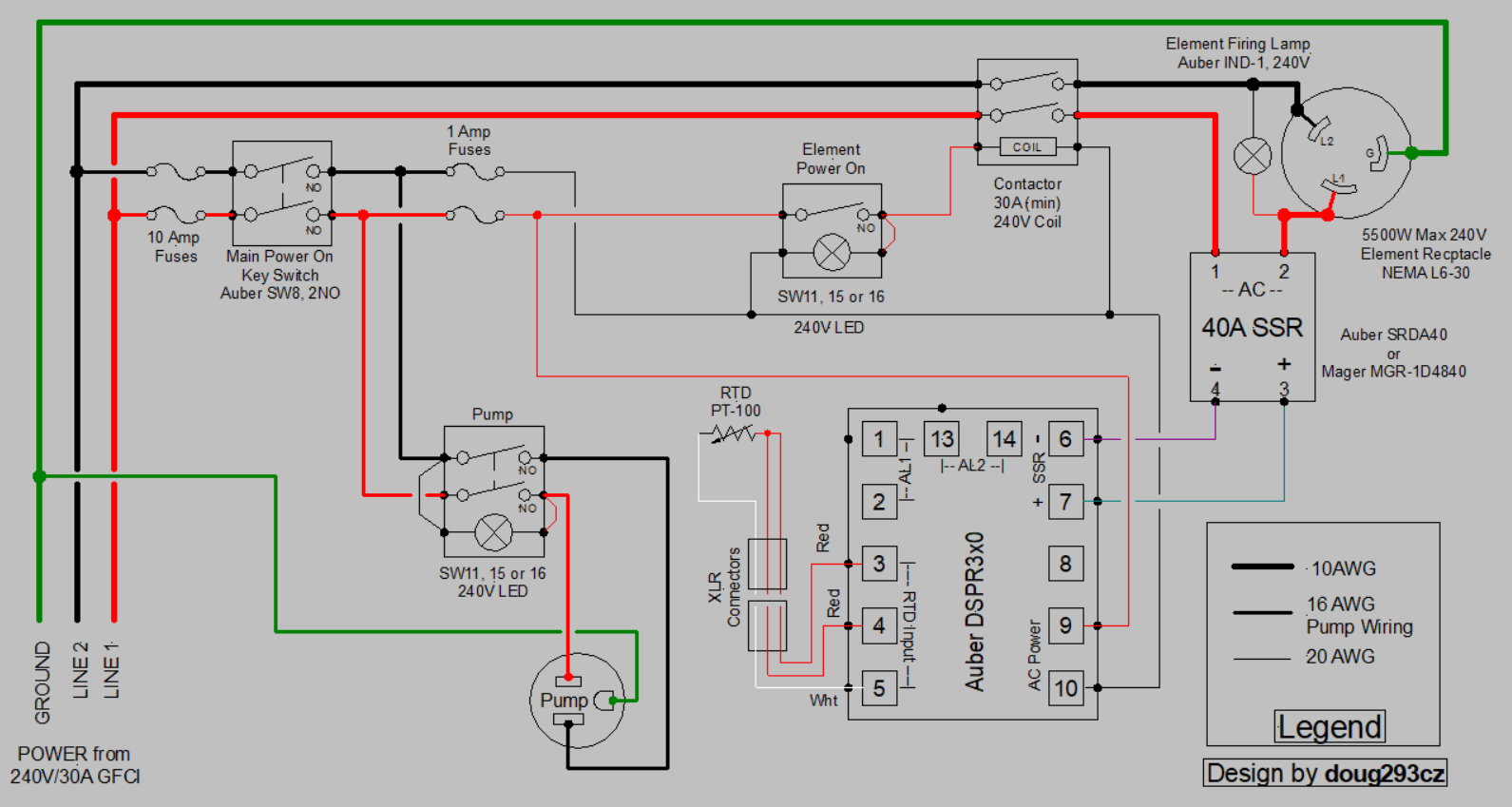

If the DC power supply is rated for something like 85 - 250VAC input, just connect the two hots to the power supply. If one of the inputs is labeled "Neutral" connect a hot to it. Do not mix up ground and neutral as doing so will cause your GFCI to trip.The split phase (2 hot, 1 ground) complicates things in my head. I'm pretty sure I can use a normal 110-220v ac/dc powersupply to get 5v and hook up hot1 and hot2 to hot and neutral on the ac/dc powersupply. I'm a bit confused on the SSR setup, would I just hook up 1 hot to the SSR and treat the other one as neutral? Then each half phase the SSR is alternating between switching hot and neutral?

Maybe a contactor is more appropriate? What about using 2 SSR, 1 for each half phase, that would also help distribute heat.

With an SSR, you only want one hot going thru an SSR, as using two SSRs will double the power "wasted" in the SSRs (25 - 35W in each one.) An SSR is not a perfect, or galvanically isolating switch (doesn't remove voltage). Think of an SSR as a current modulator with high current and very low current conduction states. Here's an equivalent circuit model for an SSR that will help you understand what an SSR looks like electrically:

Here's a simple design that shows how an SSR and contactor can be used:

The contactor provides galvanic isolation of the element from the input power. This can be advantageous, as the most common failure mode for SSRs is latched in the "ON" state. Without the galvanic isolator, you would have to unplug a live 240V circuit from the wall while it is pulling ~23A, which will give you some startling arcing when you do it.

You would substitute your microcontroller for the DSPR.

Brew on

RePete

Well-Known Member

Hi John.I used my 3.1.1 to brew today, still refining my process. I did notice that at a simmer it only read 206, and at a boil 208. I'm only about 130' above sea level, not enough to make a difference. Which makes me think my unit needs calibration. But when draining after cleaning, the water coming out tested almost exactly at the reading. Suggestions?

I did calibrate my unit by a couple degrees. It has been a few years, so I forget exactly. But on my Brewzilla, I normally set the temp to 219 and let it rip. One of the early complaints of these 110v units was that the boil wasn’t strong, but I just set it a bit high and generally get a strong boil.

I just searched for how far above sea level. Answers were from 482 to 741. One site said 629 ft, so I‘lL go with that as a middle ground. There are a lot of hills around here Which probably accounts for the variance.

RePete

Well-Known Member

Good to see people still posting on this thread. I haven’t been brewing near as much recently, or checking in here. Just restocked on some supplies, and may brew today. My last one was a pale ale which turned out well. This one will be the Dortmunder Lager recipe that’s become my standard brew. My taste has really shifted from favoring IPA’s to lagers the past couple of years. This Robobrew/Brewzilla unit is still going strong. Love it.

ShaneB

Well-Known Member

I recently got a 35L digimash, I also have an anvil pump. If I hook up the pump to the digimash is it essentially a robobrew? Can I use the robobrew equipment profile in brewfather?

DuncB

Well-Known Member

It's a 35 litre digimash? With a maltpipe I'd say same profile.

- Joined

- Jan 28, 2013

- Messages

- 3,926

- Reaction score

- 3,026

I recently got a 35L digimash, I also have an anvil pump. If I hook up the pump to the digimash is it essentially a robobrew? Can I use the robobrew equipment profile in brewfather?

I'd say pretty close, remember your numbers may vary slightly based on where you are in the world, elevation, temperature, etc.

I used my 3.1.1 to brew today, still refining my process. I did notice that at a simmer it only read 206, and at a boil 208. I'm only about 130' above sea level, not enough to make a difference. Which makes me think my unit needs calibration. But when draining after cleaning, the water coming out tested almost exactly at the reading. Suggestions?i

I've got a obout 40 brews into my 35L 110 volt Brewzilla, I've tried calibrating it with ice water and at boil, it seems that if I adjusted one end the other was off, i mainly care about the boil, it tops out at 219,my temp for mashing in needs to be about 9 degrees over what my desired temp is, I use a thermometer in my mash to control my temp, I do mostly step mashed rather than a single infusion mash, I have no.issues, still beats propane IMHO,that being said, I run the jacket, and a steam trap with 3" viewing window, once I get past the hot break, the cover and trap go on and I get a vigorous boil with only the 1000 w heater,my boil off rate for a 5 gallon 1 hour boil is 1 gallon, even with the steam trap,, very close to what it was"free willy," I always use rice hulls, 8 ounces if using wheat,I leave the silicone grain cap on and pay attention to.my mash,stiringvevery 15 minutes, cycling the pump off and on as needed.,I tried the plastic sight glass and found them brittle, I've since gone to a glass sight glass and am happy,, doing this(cycling the pump) will eliminate any scorching from a dry boiler.. I use a pulley to pull the malt tube, or hold it higher for larger grain Bill's, my sparge water is adjusted to 5.6 and heated to 170 in a 5 gallon cooler fitted with a 500 w heating element controlled by an inkbird controler, a small pump is used to pump.my sparge water... I use a modified hop spider that is held across the malt pipe rests so I can make late hop additions through the top of the steam trap..I dont measure efficiency, my numbers are good, I ferment well, the beer is good , it's all I care about.

Thanks, that's very helpful!

Bottoms_Up

Well-Known Member

That's the most important key to using the Brewzilla, in my experience. I completely disregard the temperature as reported by the Brewzilla (not at all reliable), and rely entirely on the temperature probe inserted in my mash during the entire mash. I use an Inkbird meat probe thermometer (the long probe is attached to a long metallic lead and inserted into the centre hole of the top filter screen), which makes all the difference, and adjust the target temperature accordingly. I also make sure to set the pump at about 50%, since it allows the wort near the heating element to heat properly before recirculating, rather than passing directly down the drain without much chance of reheating.I use a thermometer in my mash to control my temp

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 2K

- Views

- 203K

- Replies

- 32

- Views

- 13K