Ninoid

Well-Known Member

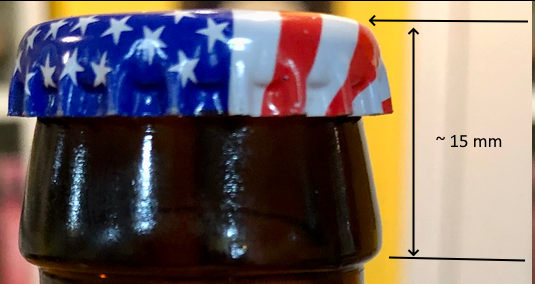

It's possible, but would it also depend on the amount and condition of the yeast? From my split-bottle trials, it was clear to me that using fresh yeast (CBC-1 or EC-1118) resulted in faster carbonation (5 to 7 days) than using whatever strain fermented the wort (10-14 days). Warmer temperature (75F) helped when using fresh yeast, but didn't make much difference when using the existing yeast.

Did you use a whole bag of CBC-1 or EC-1118 yeast for a 5 gallon batch? You probably mixed it into the bottling bucket along with the priming sugar?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)