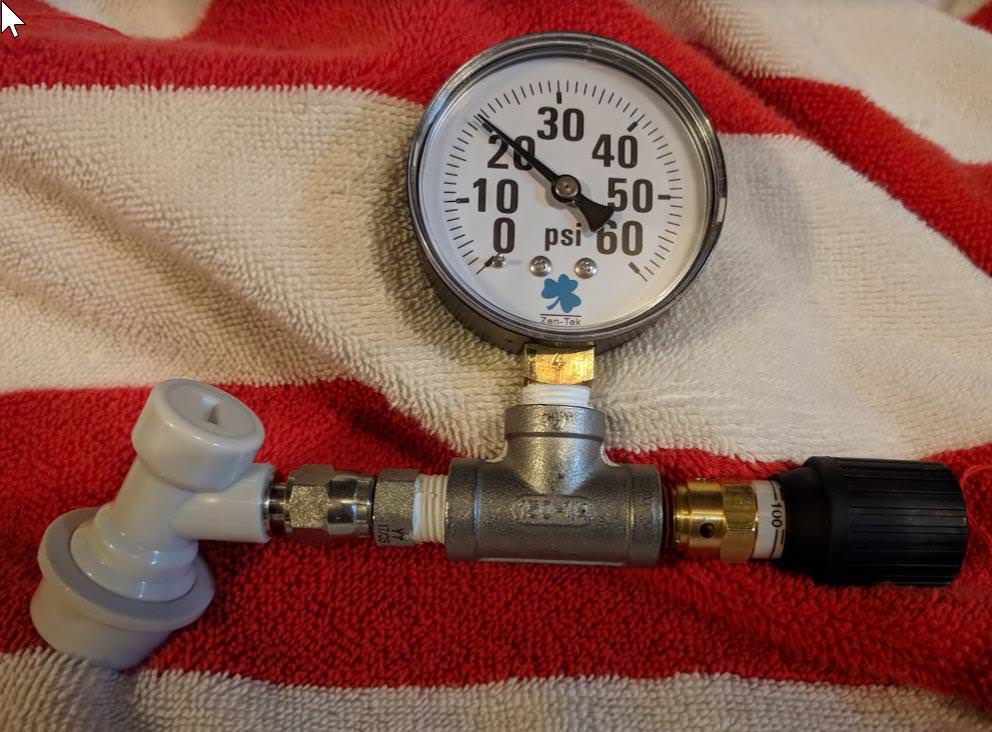

The other day I built a spunding valve as described here:

http://www.homebrewfinds.com/2011/02/build-spunding-valve.html

When I pop the valve off a pressurized keg, the gauge continues to show pressure as you'd expect... but the assembly does lose pressure over time, about 5 PSI per day. So the assembly isn't airtight... but is it close enough?

The gas volume in the detached assembly has got to be very small compared to the headspace in a keg. If I submerge the whole assembly while pressurized, I can't even see bubbles.

Is it good 'nuff or should I try to tighten all the parts more? I'm not sure I can turn anything much further, it's all very tight already.

http://www.homebrewfinds.com/2011/02/build-spunding-valve.html

When I pop the valve off a pressurized keg, the gauge continues to show pressure as you'd expect... but the assembly does lose pressure over time, about 5 PSI per day. So the assembly isn't airtight... but is it close enough?

The gas volume in the detached assembly has got to be very small compared to the headspace in a keg. If I submerge the whole assembly while pressurized, I can't even see bubbles.

Is it good 'nuff or should I try to tighten all the parts more? I'm not sure I can turn anything much further, it's all very tight already.