wyzazz

Well-Known Member

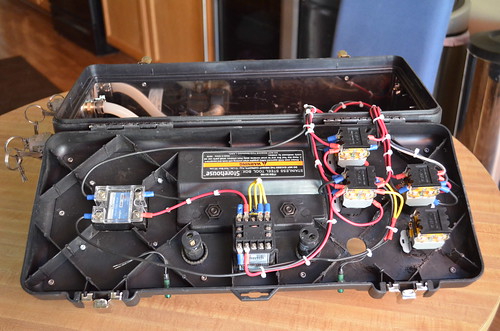

Well, here she is! I didn't integrate a GFCI since all the outlets I use are GFCI protected & all the parts I used were from my parts bin in the garage. The receptacle and switch are from an old EMC UPS, the plumbing parts I had lying around in my plumbing box. I picked up the toolbox with a 20% off coupon and used an old extension cord instead of the small power strip. I put washers on either side of the camlocks for some stability, no issues yet with the ball valve getting torqued too much.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)