I switched out all my carboys for the big bubblers. I do like them – a lot…..But I am frustrated with a few things as well.

1) The lid just sucks. I am not getting bubbling on my airlock either. I did finally get it on my last batch but I had to push the stopper down REALLY hard into that middle plastic hole for it to start. I’ve also noticed that turning of the lid really tight does not ensure a tight seal. For some reason I’m able to turn it even a little more after a few days. It’s like it becomes unlocked somehow.

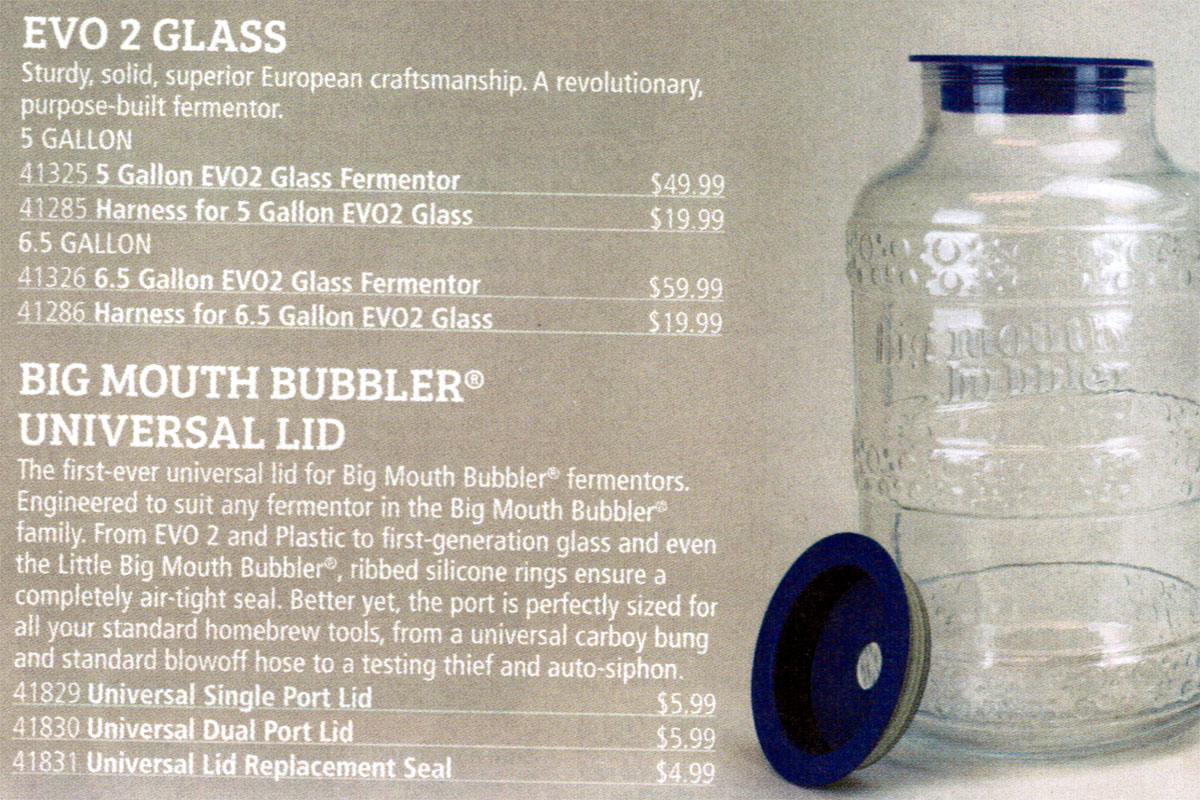

2) The glass is thin – although I did buy the harness and the harness actually protects it adequately. I could see how if you skimped on the harness that the glass would really scare me.

3) The lid again – needs a spot for thermowell

4) The manufacturer needs to make replacement lids and distribute them.

I’m so frustrated with the lid that I am thinking of trying to design one myself. Everything else about the bubbler is fantastic.

1) The lid just sucks. I am not getting bubbling on my airlock either. I did finally get it on my last batch but I had to push the stopper down REALLY hard into that middle plastic hole for it to start. I’ve also noticed that turning of the lid really tight does not ensure a tight seal. For some reason I’m able to turn it even a little more after a few days. It’s like it becomes unlocked somehow.

2) The glass is thin – although I did buy the harness and the harness actually protects it adequately. I could see how if you skimped on the harness that the glass would really scare me.

3) The lid again – needs a spot for thermowell

4) The manufacturer needs to make replacement lids and distribute them.

I’m so frustrated with the lid that I am thinking of trying to design one myself. Everything else about the bubbler is fantastic.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)