Yep, writing on the wall for years and all of their crap finally caught up to them... This quote from the article is the best news I've heard in years "And yesterday, the founder team (Bill Mitchell, his brother Jim Mitchell and Avi Geiger) was let go, along with the customer service team. " Not everyone at PB was horrible, but two guys in particular had a hand in its failure.

It's no big deal though, my Zymatic has been running issue free since I started my own maintenance and cleaning regimen along with a few needed mods. It does mean that I'll need to accelerate my RPi development...

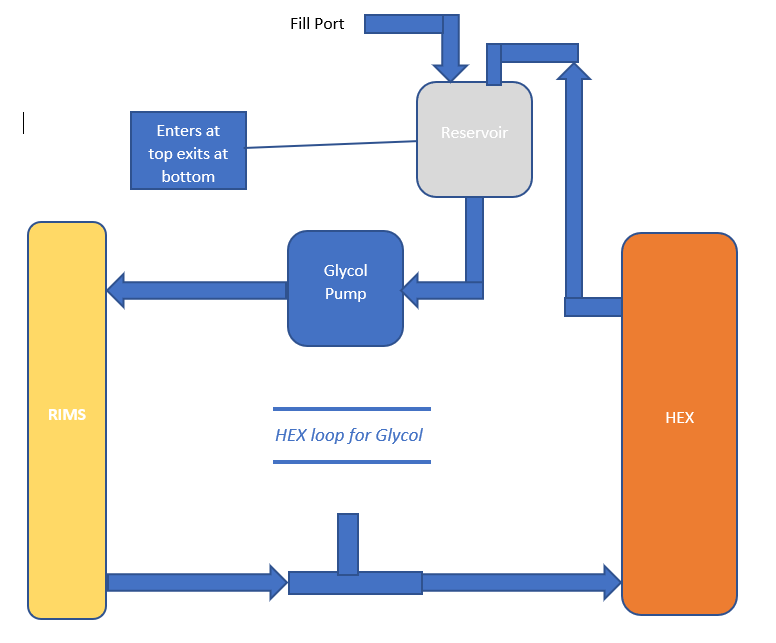

As I've mentioned before, I'll gladly donate to the RPi development cause. I'm actually topping off the glycol in the hex loop today, thanks to your very detailed instructions. Really appreciate it.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)