I haven't even seen one person post that got the new Z....my guess is the regular supporters are still a ways out. Besides, I think Picobrew is having a heck of a time with fulfilling requests for any of their products. Case in point: Picostill Delivery

Since I got my new Brew-Boss I am less anxious about delivery dates and feedback. Except, I am curious about the MTBF on the new Z series and if anyone will post about a part gone bad that Picobrew let them replace (pet peeve). I foresee that the new wort distribution system could be problematic, but only time will tell. Also, given my experience, I am curious about the upgraded HEX system.

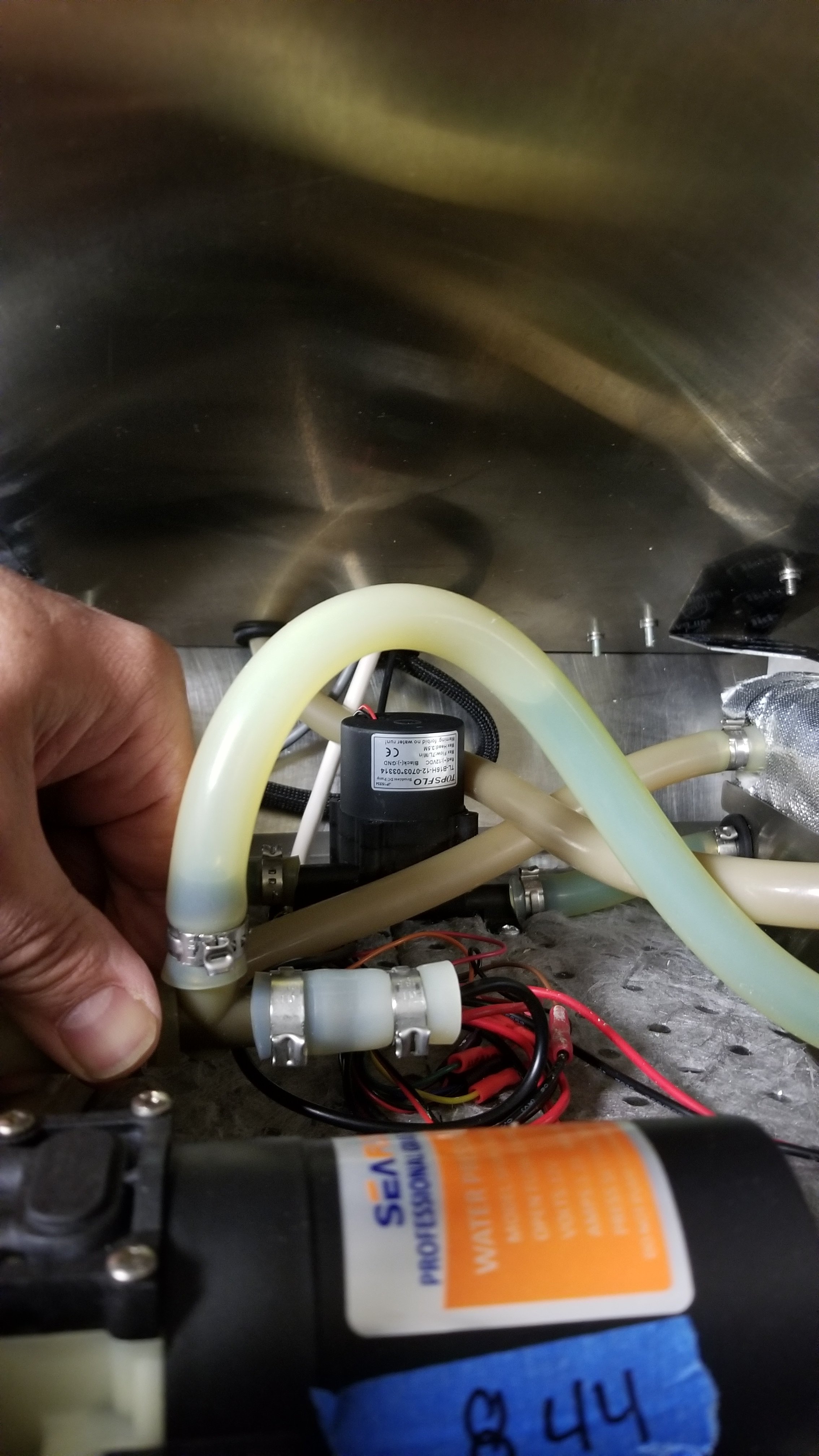

I have about 150 brews (last count) on my Zymatic and so far I have had to rebuild the stepper arm, top off the glycol (3 times), replace the RIMS heating element, repair the grain bin screens and fix a drain pump diaphragm clog...all without the help of picobrew I might add (snarky remark).

I am wondering why Picobrew hasn't made a lot of fanfare about the release of the new Z and any feedback they have received? They made a big deal about that first delivery and now nothing? Is it not going as planned? Are folks not excited? Did the new software upgrades pan out like they wanted? IDK, just enquiring.

Since I got my new Brew-Boss I am less anxious about delivery dates and feedback. Except, I am curious about the MTBF on the new Z series and if anyone will post about a part gone bad that Picobrew let them replace (pet peeve). I foresee that the new wort distribution system could be problematic, but only time will tell. Also, given my experience, I am curious about the upgraded HEX system.

I have about 150 brews (last count) on my Zymatic and so far I have had to rebuild the stepper arm, top off the glycol (3 times), replace the RIMS heating element, repair the grain bin screens and fix a drain pump diaphragm clog...all without the help of picobrew I might add (snarky remark).

I am wondering why Picobrew hasn't made a lot of fanfare about the release of the new Z and any feedback they have received? They made a big deal about that first delivery and now nothing? Is it not going as planned? Are folks not excited? Did the new software upgrades pan out like they wanted? IDK, just enquiring.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)