Sublime8365

Well-Known Member

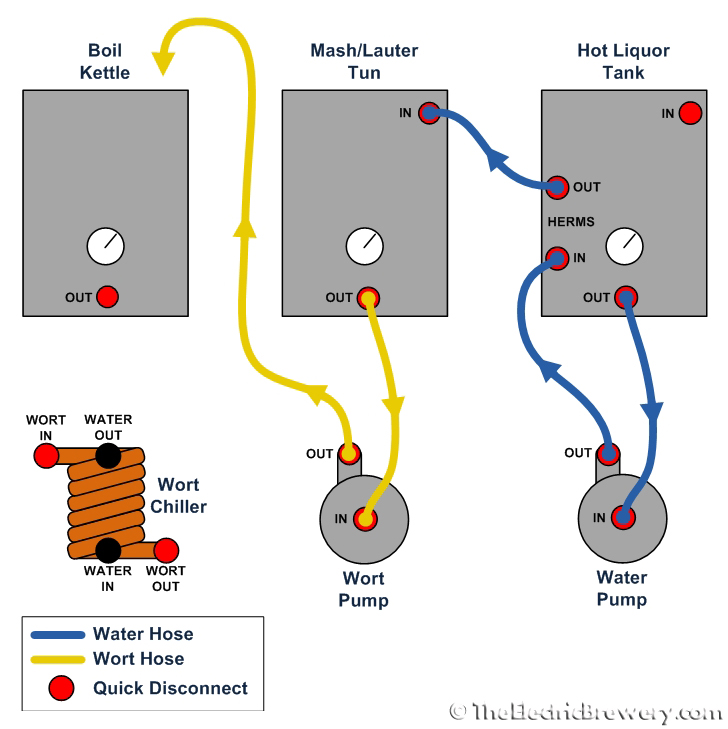

So for my HERMS system I just recently switch to an RTD setup similar to this:

https://www.homebrewtalk.com/f51/how-pt100-rtd-1-2-npt-thermowell-225215/

Problem is that I don't typically use any temperature sensing for the boil but when I unplug the RTD, I get the orAL error because there's an open circuit. Is there any way to get past the orAL error and just use the manual setting to control the BK element? It's kind of annoying to have to keep the RTD plugged into the HLT during the boil just so the orAL error won't show up.

https://www.homebrewtalk.com/f51/how-pt100-rtd-1-2-npt-thermowell-225215/

Problem is that I don't typically use any temperature sensing for the boil but when I unplug the RTD, I get the orAL error because there's an open circuit. Is there any way to get past the orAL error and just use the manual setting to control the BK element? It's kind of annoying to have to keep the RTD plugged into the HLT during the boil just so the orAL error won't show up.