@JAReeves how does it come out this way?

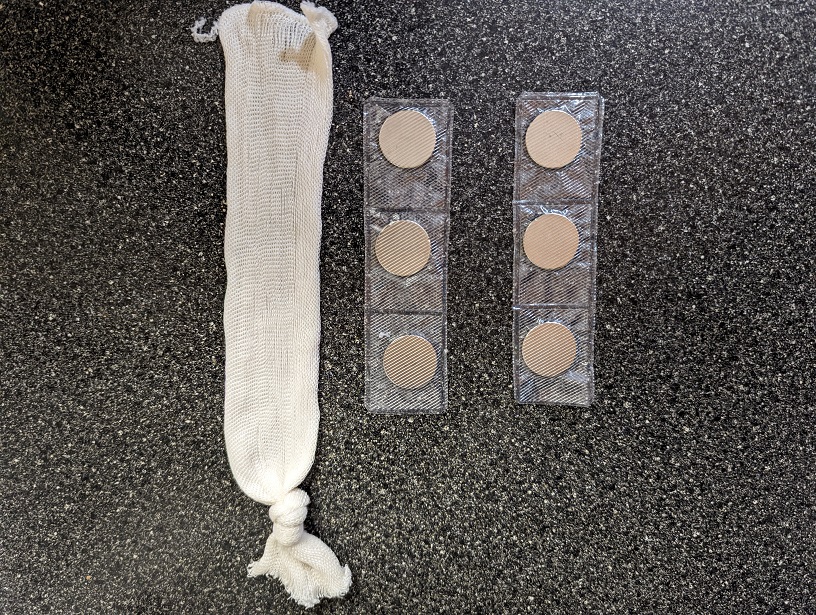

I'm definitely going with the tea bag method on my next batch. I bought really strong magnets and tonight I vacuum sealed them in units small enough to fit into a muslin bag and I tested them on a corny keg. They are super strong and I do not see them having an issue holding up a wet bag of hops.

I'm definitely going with the tea bag method on my next batch. I bought really strong magnets and tonight I vacuum sealed them in units small enough to fit into a muslin bag and I tested them on a corny keg. They are super strong and I do not see them having an issue holding up a wet bag of hops.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)