Try all distilled water and build back from there with additions. if you do that and it works well, you can maybe start cutting it with tap water to see how it performs.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Opinions needed for my IPA recipe Citra/Amarillo

- Thread starter mastroiani

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

mastroiani

Active Member

- Joined

- Jul 2, 2016

- Messages

- 25

- Reaction score

- 3

I've found the composition for a bottled water i can buy here, i dont know much about water profiles so tell me what you think about the numbers

I've tested the PH with a strip and it shows that is around 6.2

Dry residue - 137 ppm

Alkalinity… 111 ppm

Ca - 35 ppm

Mg - 9,5 ppm

Na - 6,8 ppm

K - 0,7 ppm

Cl - 6,99 ppm

NO3 - 2,5 ppm

SO4 - 2,5 ppm

let me know what you think

I've tested the PH with a strip and it shows that is around 6.2

Dry residue - 137 ppm

Alkalinity… 111 ppm

Ca - 35 ppm

Mg - 9,5 ppm

Na - 6,8 ppm

K - 0,7 ppm

Cl - 6,99 ppm

NO3 - 2,5 ppm

SO4 - 2,5 ppm

let me know what you think

mastroiani

Active Member

- Joined

- Jul 2, 2016

- Messages

- 25

- Reaction score

- 3

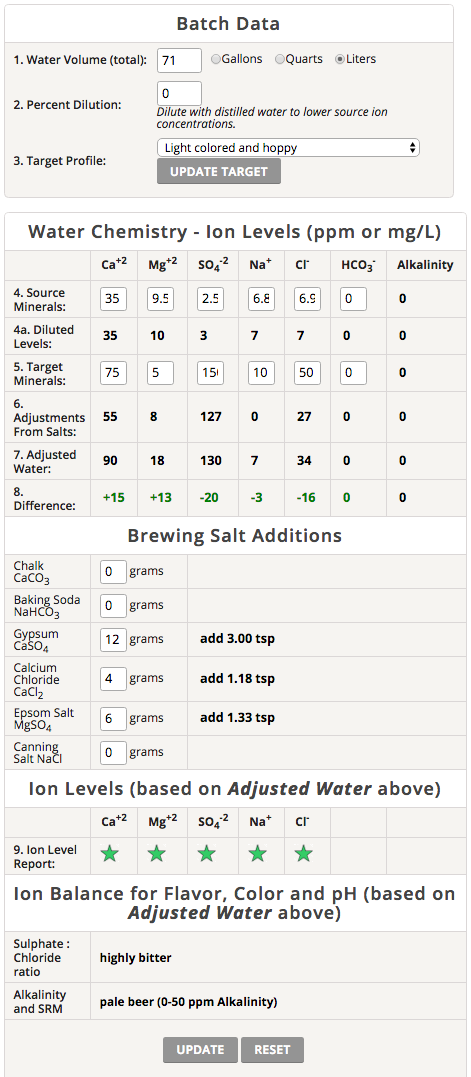

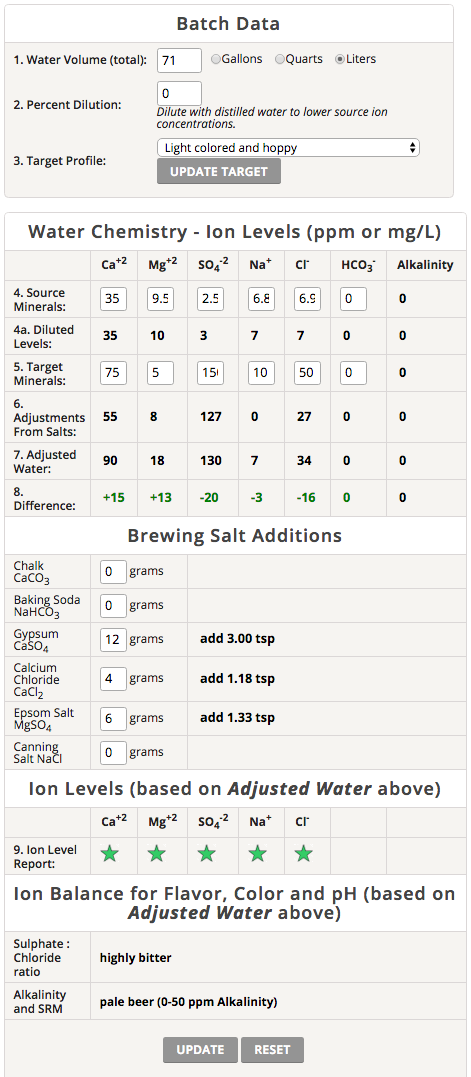

Im not sure if this is ok, but i entered the water profile in an online water profile calculator and the result with that water is that i have to add 0.4 oz of Gypsum, 0.14 oz of Calcium Chloride and 0.2 oz of MgSO4 (Epsom Salt)

Is this right?

Thanks!

Is this right?

Thanks!

crusader1612

Well-Known Member

Im not sure if this is ok, but i entered the water profile in an online water profile calculator and the result with that water is that i have to add 0.4 oz of Gypsum, 0.14 oz of Calcium Chloride and 0.2 oz of MgSO4 (Epsom Salt)

Is this right?

Thanks!

Have you got a link to that?

mastroiani

Active Member

- Joined

- Jul 2, 2016

- Messages

- 25

- Reaction score

- 3

Yes of course, the link is http://www.brewersfriend.com/water-chemistry/

mastroiani

Active Member

- Joined

- Jul 2, 2016

- Messages

- 25

- Reaction score

- 3

Folks, just the last question...

When do i have to add each salt?

Gypsum, Calcium Chloride and MgSO4 all in the mash?

Thanks!

When do i have to add each salt?

Gypsum, Calcium Chloride and MgSO4 all in the mash?

Thanks!

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

JordanKnudson

Well-Known Member

Folks, just the last question...

When do i have to add each salt?

Gypsum, Calcium Chloride and MgSO4 all in the mash?

Thanks!

If your goal with the salts is to adjust mash pH, then yes, add them to the mash. Some folks will tell you to add them directly to the mash (to make sure it all actually get into the mash), others will tell you to add them to your strike water (to ensure even dispersal). Either way you do it, you want to make sure your salts are going in at the beginning of the mash.

Kettle additions are for mineral flavor profile. Obviously, at that point, your mash is already done.

One thing...I don't typically use Epsom Salt [MgSO4] in my beers unless it is for a very specific purpose. According to Gordon Strong, it promotes a sour flavor when used above a fairly low threshold (every beer I've used it in has been lousy, but I can't say definitively that it was just the salt). You can definitely get by with just gypsum or calcium chloride, or a combination of the two.

mastroiani

Active Member

- Joined

- Jul 2, 2016

- Messages

- 25

- Reaction score

- 3

I was planning to add citric acid to lower the PH, and gypsum and calcium chloride for flavour. I was only thinking of using the epsom salt just because the water profile i got from that calculator.

JordanKnudson

Well-Known Member

I was planning to add citric acid to lower the PH, and gypsum and calcium chloride for flavour. I was only thinking of using the epsom salt just because the water profile i got from that calculator.

Ah, I see. Then add your salts to the kettle.

I would start with just gypsum and calcium chloride and see what they do for you. I don't like to add salts "just because." Try to have a reason for anything that you are putting in your beer, and remember that overdoing the salt additions can leave your beer tasting like alka-seltzer.

To that end, I would think about the balance of gypsum and calcium chloride that you want and what you're trying to get out of them. Gypsum tends to bring out hop bitterness and lend itself to a crisp beer; calcium chloride accentuates the perception of soft malt. If you aren't sure which way to go, try adding both in a 1:1 ratio and limiting the total to no more than 1 teaspoon per 5 gallons.

EDIT: added the qualification "per 5 gallons," because I just remembered that I think you are making a larger batch size.

mastroiani

Active Member

- Joined

- Jul 2, 2016

- Messages

- 25

- Reaction score

- 3

Ah, I see. Then add your salts to the kettle.

I would start with just gypsum and calcium chloride and see what they do for you. I don't like to add salts "just because." Try to have a reason for anything that you are putting in your beer, and remember that overdoing the salt additions can leave your beer tasting like alka-seltzer.

To that end, I would think about the balance of gypsum and calcium chloride that you want and what you're trying to get out of them. Gypsum tends to bring out hop bitterness and lend itself to a crisp beer; calcium chloride accentuates the perception of soft malt. If you aren't sure which way to go, try adding both in a 1:1 ratio and limiting the total to no more than 1 teaspoon per 5 gallons.

EDIT: added the qualification "per 5 gallons," because I just remembered that I think you are making a larger batch size.

I was thinking of 2.5 tbsp of gypsum and 1 calcium chloride, in order to accentuate the hop bitternes but with a subtle perception of maltyness

I dont know much about the water chemistry, everything i planned to do was because of reading threads in this forum and the water chem calculator.

I'll let you know how this turn out thanks to all!

I was thinking of 2.5 tbsp of gypsum and 1 calcium chloride, in order to accentuate the hop bitternes but with a subtle perception of maltyness

I dont know much about the water chemistry, everything i planned to do was because of reading threads in this forum and the water chem calculator.

I'll let you know how this turn out thanks to all!

Can't recommend the Water book enough. It can be had used from amazon fairly cheap. I think there is a Kindle edition as well, if shipping is an issue. Note, citric acid can impart flavor, though I use it in my ipas exclusively because I think the flavor does contribute to a citrusy ale. Just go slow with it. Add half or less to your strike then test your pH after mash in and conversion starts. Then add as needed. Or mash in, wait, test, add, test, wait, test, add as needed. Especially considering you are not 100% sure on your water. I learned that the hard way. See 4.9 pH on a mash. And about a teaspoon and a half dropped it there in a 12g batch. A little goes a long way. Keep those enzymes happy

mastroiani

Active Member

- Joined

- Jul 2, 2016

- Messages

- 25

- Reaction score

- 3

Great advice, i will download Water book.

My idea was to mash in, test the ph and then add the citric acid. Should i disolve it in water or just add directly to the mash?

Thanks!

My idea was to mash in, test the ph and then add the citric acid. Should i disolve it in water or just add directly to the mash?

Thanks!

mastroiani

Active Member

- Joined

- Jul 2, 2016

- Messages

- 25

- Reaction score

- 3

Im brewing this beer on wednesday, so i was reading some articles and some threads here and i get some questions that could make my beer a little better, according on what i've read.

This is my recipe in Beersmith 2.0

Efficency - 70%

Est. OG - 1.060

IBUs - 55

Color - 8.9

Est. ABV - 6.5%

30.4 lbs. 2 Row - 97.5%

0.22 lb. Crystal - 0.7%

0.5 lb Carapils - 1.8%

0.45 oz Gypsum (boil addition)

0.2 oz Calcium Chloride (boil addition)

0.1 Epson salt (boil addition)

1.5 Tablets Whirfloc

1.4 oz. Columbus (14% AA) 60 min.

2.1 oz. Cascade (5.5% AA) 10 min.

2.1 oz.Amarillo (7.7% AA) 7 min.

2.1 Citra (13.6% AA) 5 min.

2.5 oz. Citra (13.6% AA) Whirlpool

2 oz. Amarillo (7.7% AA) Whirlpool

4 oz. Citra (13.6% AA) Dryhopping 5 days

2.5 oz. Amarillo (7.7% AA) Dryhopping 5 days

3 packets US-05

Mash at 147/150 for 60 minutes, sparge to boil volume

-----------------------------------------------------------------------------

And the 2 questions i have are:

1- I've never done FWH, but ive read that it gives a smoother and rounder bitternes, so do you think its a good idea to add instead of 1.4 oz Columbus @ 60 min, add 0.7 oz @ FWH and 0.7 @ 60 min?

2- I've also read that long periods of dryhopping can give astringency to the beer, i've always done 7 days for dryhopping, do you think its better 5 days? Would i lose some aroma with less days?

And really thank you all, im really trying to learn everything i can, and all your answers were very helpful!

This is my recipe in Beersmith 2.0

Efficency - 70%

Est. OG - 1.060

IBUs - 55

Color - 8.9

Est. ABV - 6.5%

30.4 lbs. 2 Row - 97.5%

0.22 lb. Crystal - 0.7%

0.5 lb Carapils - 1.8%

0.45 oz Gypsum (boil addition)

0.2 oz Calcium Chloride (boil addition)

0.1 Epson salt (boil addition)

1.5 Tablets Whirfloc

1.4 oz. Columbus (14% AA) 60 min.

2.1 oz. Cascade (5.5% AA) 10 min.

2.1 oz.Amarillo (7.7% AA) 7 min.

2.1 Citra (13.6% AA) 5 min.

2.5 oz. Citra (13.6% AA) Whirlpool

2 oz. Amarillo (7.7% AA) Whirlpool

4 oz. Citra (13.6% AA) Dryhopping 5 days

2.5 oz. Amarillo (7.7% AA) Dryhopping 5 days

3 packets US-05

Mash at 147/150 for 60 minutes, sparge to boil volume

-----------------------------------------------------------------------------

And the 2 questions i have are:

1- I've never done FWH, but ive read that it gives a smoother and rounder bitternes, so do you think its a good idea to add instead of 1.4 oz Columbus @ 60 min, add 0.7 oz @ FWH and 0.7 @ 60 min?

2- I've also read that long periods of dryhopping can give astringency to the beer, i've always done 7 days for dryhopping, do you think its better 5 days? Would i lose some aroma with less days?

And really thank you all, im really trying to learn everything i can, and all your answers were very helpful!

The app deleted my post but I'll redo I guess...

1)I've never found fwh to be eye opening different. Hops boiled for an hour are hops boiled for an hour. I think it's just dogma. I forget the whole story but I think it was something about FWH starting at a German brewery that thought that it achieved better bitterness but then they changed their mind and went back to boil additions. You'll make good beer either way.

2) 2-3 days is my usual dry hop time, with another 2-3 cold crashing. All in primary. Length depends on life and schedules. I have gotten grassy notes (tastes like frrsh grass clippings smell) from a long centennial dry hop, 8 days iirc).

I think you achieve most if not all of the benefits of DH in a couple days, if not just a few minutes. Hop Randalls do wonders, and the beer only touches the hops for a few seconds.

My .02

1)I've never found fwh to be eye opening different. Hops boiled for an hour are hops boiled for an hour. I think it's just dogma. I forget the whole story but I think it was something about FWH starting at a German brewery that thought that it achieved better bitterness but then they changed their mind and went back to boil additions. You'll make good beer either way.

2) 2-3 days is my usual dry hop time, with another 2-3 cold crashing. All in primary. Length depends on life and schedules. I have gotten grassy notes (tastes like frrsh grass clippings smell) from a long centennial dry hop, 8 days iirc).

I think you achieve most if not all of the benefits of DH in a couple days, if not just a few minutes. Hop Randalls do wonders, and the beer only touches the hops for a few seconds.

My .02

But why such odd measurements?

Super concentrated on 55ibu and 6.5%?

Also, when you whirlpool, wait until you drop the temp some (I target 165-170F) before adding those hops to avoid over bittering. You will pick up some ibus from WP, but not as many if you drop the temp some first. Remeber, 5 minute additions are only 5 minute additions if you start chilling 5 minutes later

There are a few different opinions about time and Temps out there but I like to stay in that range because 165 is the magic number when it comes to bacteria. I brew outside and my lid (pizza pan with a cabinet handle) isn't tight fitting. If some flies or something find their way in, at least the temp of the wort will keep it safe.

Super concentrated on 55ibu and 6.5%?

Also, when you whirlpool, wait until you drop the temp some (I target 165-170F) before adding those hops to avoid over bittering. You will pick up some ibus from WP, but not as many if you drop the temp some first. Remeber, 5 minute additions are only 5 minute additions if you start chilling 5 minutes later

There are a few different opinions about time and Temps out there but I like to stay in that range because 165 is the magic number when it comes to bacteria. I brew outside and my lid (pizza pan with a cabinet handle) isn't tight fitting. If some flies or something find their way in, at least the temp of the wort will keep it safe.

mastroiani

Active Member

- Joined

- Jul 2, 2016

- Messages

- 25

- Reaction score

- 3

Thanks @Jwin!

Sorry for the odd numbers, thats because i have it all in grams, liters, etc and had to change it to ounces, pounds, etc.

Not super concentrated on 55 IBU and 6.5%, my last brew was at 7.9% ABV and 80 IBUs, and the ones before that all around 7% and 60-70 IBUs, so for this one i wanted to take it down a little bit, but mostly because previous brews were unbalanced and with astringency, maybe because of the water chem or something like that.

So for this brew i want to make a smooth but bitter, crisp and dry beer. If everything turns out fine, the next one i will probably increase the ABV and the IBUs for sure.

Sorry for the odd numbers, thats because i have it all in grams, liters, etc and had to change it to ounces, pounds, etc.

Not super concentrated on 55 IBU and 6.5%, my last brew was at 7.9% ABV and 80 IBUs, and the ones before that all around 7% and 60-70 IBUs, so for this one i wanted to take it down a little bit, but mostly because previous brews were unbalanced and with astringency, maybe because of the water chem or something like that.

So for this brew i want to make a smooth but bitter, crisp and dry beer. If everything turns out fine, the next one i will probably increase the ABV and the IBUs for sure.

JordanKnudson

Well-Known Member

Thanks @Jwin!

Sorry for the odd numbers, thats because i have it all in grams, liters, etc and had to change it to ounces, pounds, etc.

Not super concentrated on 55 IBU and 6.5%, my last brew was at 7.9% ABV and 80 IBUs, and the ones before that all around 7% and 60-70 IBUs, so for this one i wanted to take it down a little bit, but mostly because previous brews were unbalanced and with astringency, maybe because of the water chem or something like that.

So for this brew i want to make a smooth but bitter, crisp and dry beer. If everything turns out fine, the next one i will probably increase the ABV and the IBUs for sure.

Definitely your mash pH, almost without question. Of course, other things can cause astringency, but a mash pH around 6.0 or higher is known for extracting harsh tannins from the grain husks, which then contribute unpleasant astringency to the beer.

mastroiani

Active Member

- Joined

- Jul 2, 2016

- Messages

- 25

- Reaction score

- 3

I know this was mentioned before, but maybe a bit of sugar to dry it out will help with what you are after.

Ive done it in my firsts batches but never repeated again. What % do you recommend? or just test it until desired ABV?

Does table sugar works?

Table sugar is fine .5-1# per 5g

It will help dry it out a bit.

Just be sure to lower your flame when adding it and stir well

I add it in the last couple minutes, right befoee my IC, to avoid any caramelization.

It will help dry it out a bit.

Just be sure to lower your flame when adding it and stir well

I add it in the last couple minutes, right befoee my IC, to avoid any caramelization.

crusader1612

Well-Known Member

Ive done it in my firsts batches but never repeated again. What % do you recommend? or just test it until desired ABV?

Does table sugar works?

Personally with an OG of 1.060 I wouldn't bother adding sugar.

mash low and with your specialties at about 2% total of the beer, it should be nice and dry already.

If you wanted to make it drier, you could remove the carapils all together, and have about 1% specialty malts.

IMO sugar is unneccessary until you get to 1.075 and above.

mastroiani

Active Member

- Joined

- Jul 2, 2016

- Messages

- 25

- Reaction score

- 3

Thanks to all!

I'll let you know how this turn out in a couple of weeks

I'll let you know how this turn out in a couple of weeks

Thanks to all!

I'll let you know how this turn out in a couple of weeks

How did it turn out?

mastroiani

Active Member

- Joined

- Jul 2, 2016

- Messages

- 25

- Reaction score

- 3

It didnt turn out bad, but it didnt turn out great either... ive realized that some part of the equipment was leaving some off flavour to the beer, im doing a master clean up now to remove every inch of undesired stuff on my equipment.

Also ive realized that i forgot to take down the temp quickly after the boiling, so probably most of the flavor additions went to bitternes...

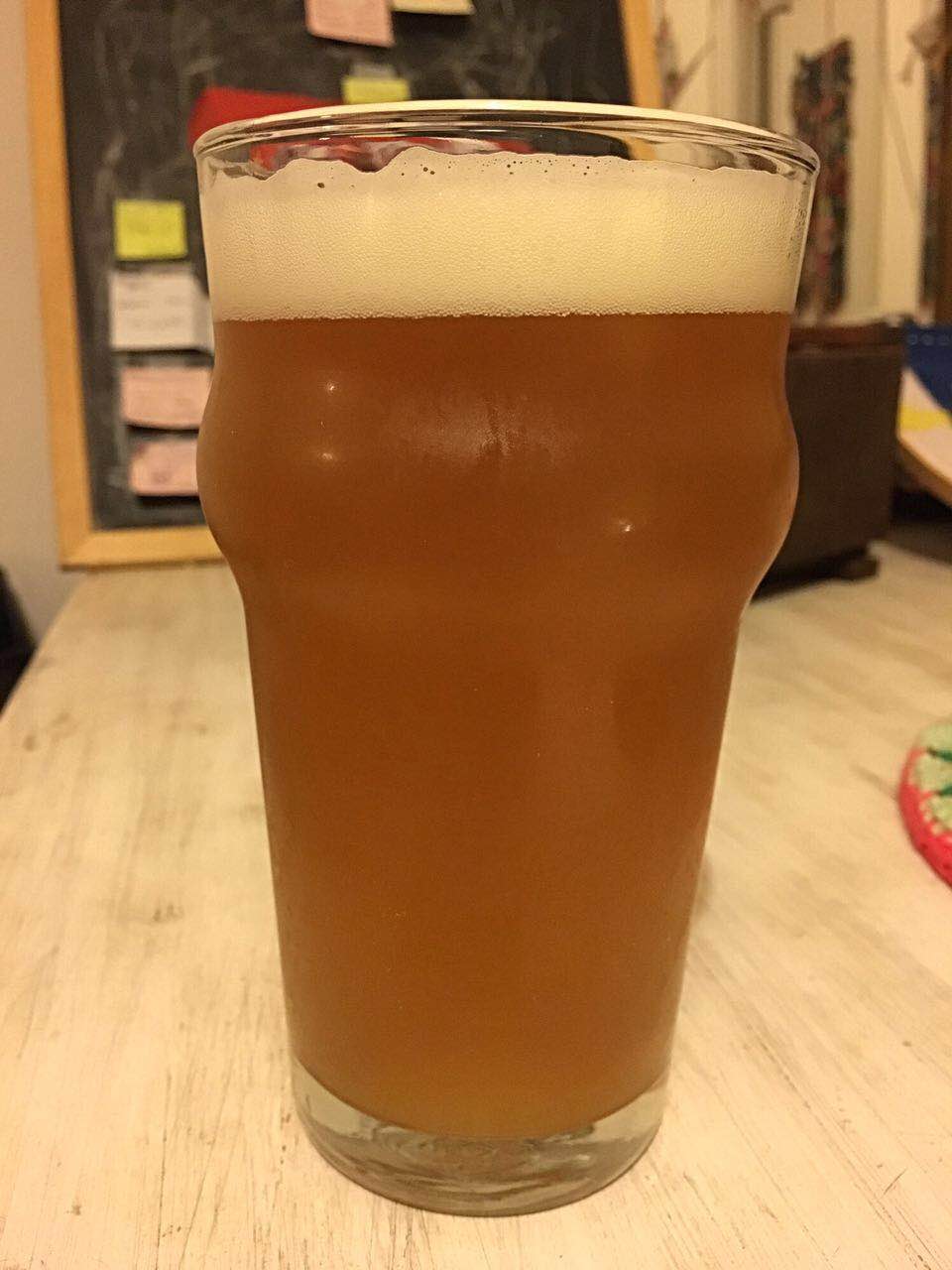

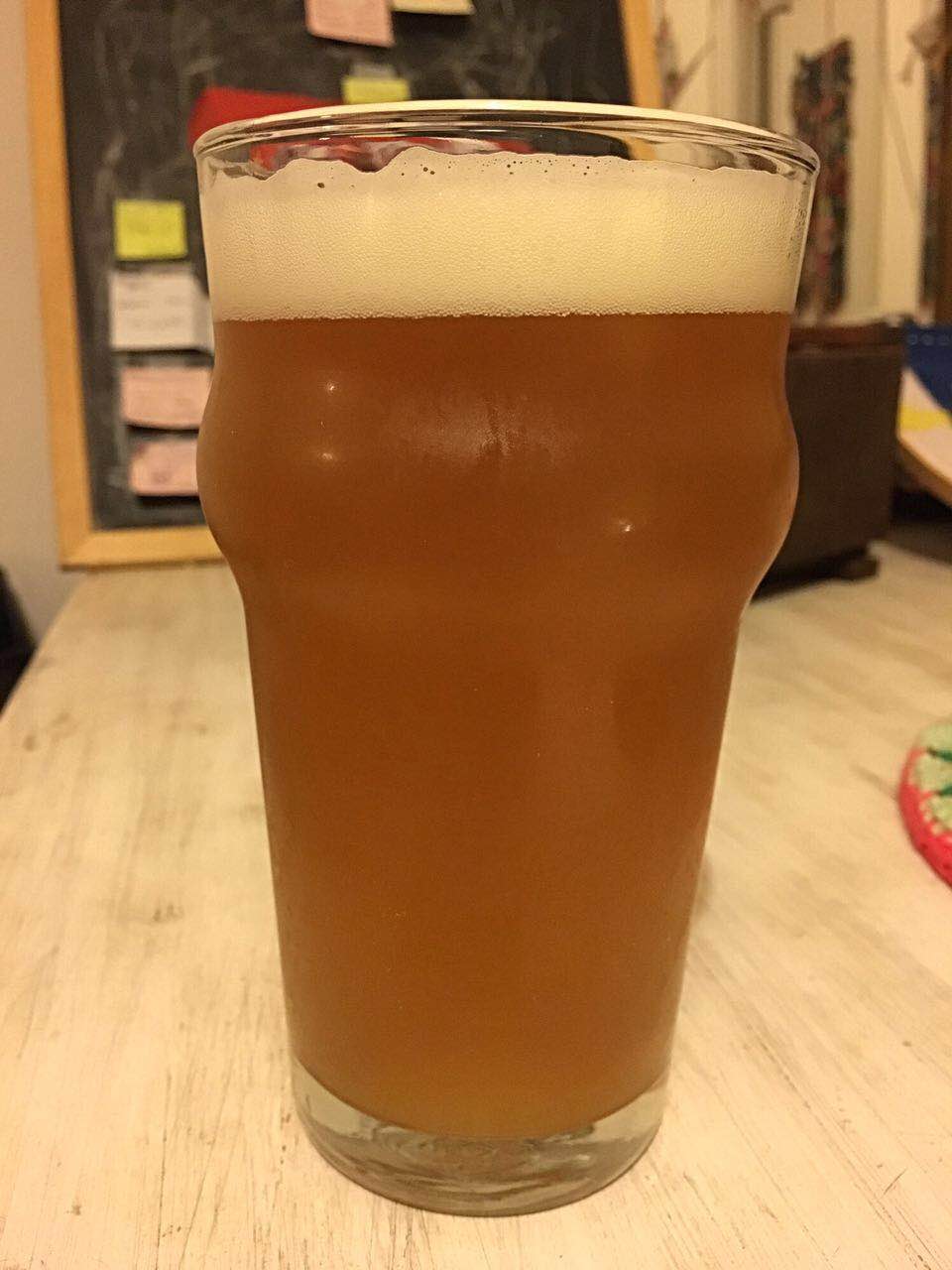

Even though all those problems its still an ok IPA... good foam, good head retention, even though i couldnt filtrate the beer (the filter wasnt working properly) i was happy with the color and no noticeable yeast or hops particles.

i will repeat the recipe but taking into consideration all the issues i have before.

Also ive realized that i forgot to take down the temp quickly after the boiling, so probably most of the flavor additions went to bitternes...

Even though all those problems its still an ok IPA... good foam, good head retention, even though i couldnt filtrate the beer (the filter wasnt working properly) i was happy with the color and no noticeable yeast or hops particles.

i will repeat the recipe but taking into consideration all the issues i have before.

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 2

- Views

- 279

- Replies

- 3

- Views

- 799

Latest posts

-

-

-

-

-

-

-

Spike Conical Heater fails again--second in 3 years--ideas?

- Latest: Indian_villager

-

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)