Prost!

Well-Known Member

- Joined

- Feb 11, 2006

- Messages

- 142

- Reaction score

- 1

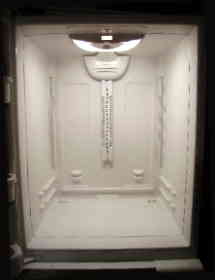

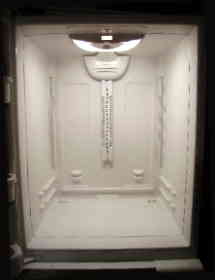

I just bought a 21.9 cubic foot Maytag fridge with freezer on the bottom (pictured below). I should be able to fit six, 5-gallon cornies, and 5+ cases of 12 oz bottles. I want to drill a single hole to run Co2 line through the back. How do I avoid wires and/or cooling elements in the back of the fridge? I'm planning on using a stud finder to detect and metal, but other than that I have no idea what I'm doing. I don't want to screw this one up. The fridge is in excellent condition and only a few years old (2003), I paid $75 for it on ebay! I'd appreciate any advice here.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)