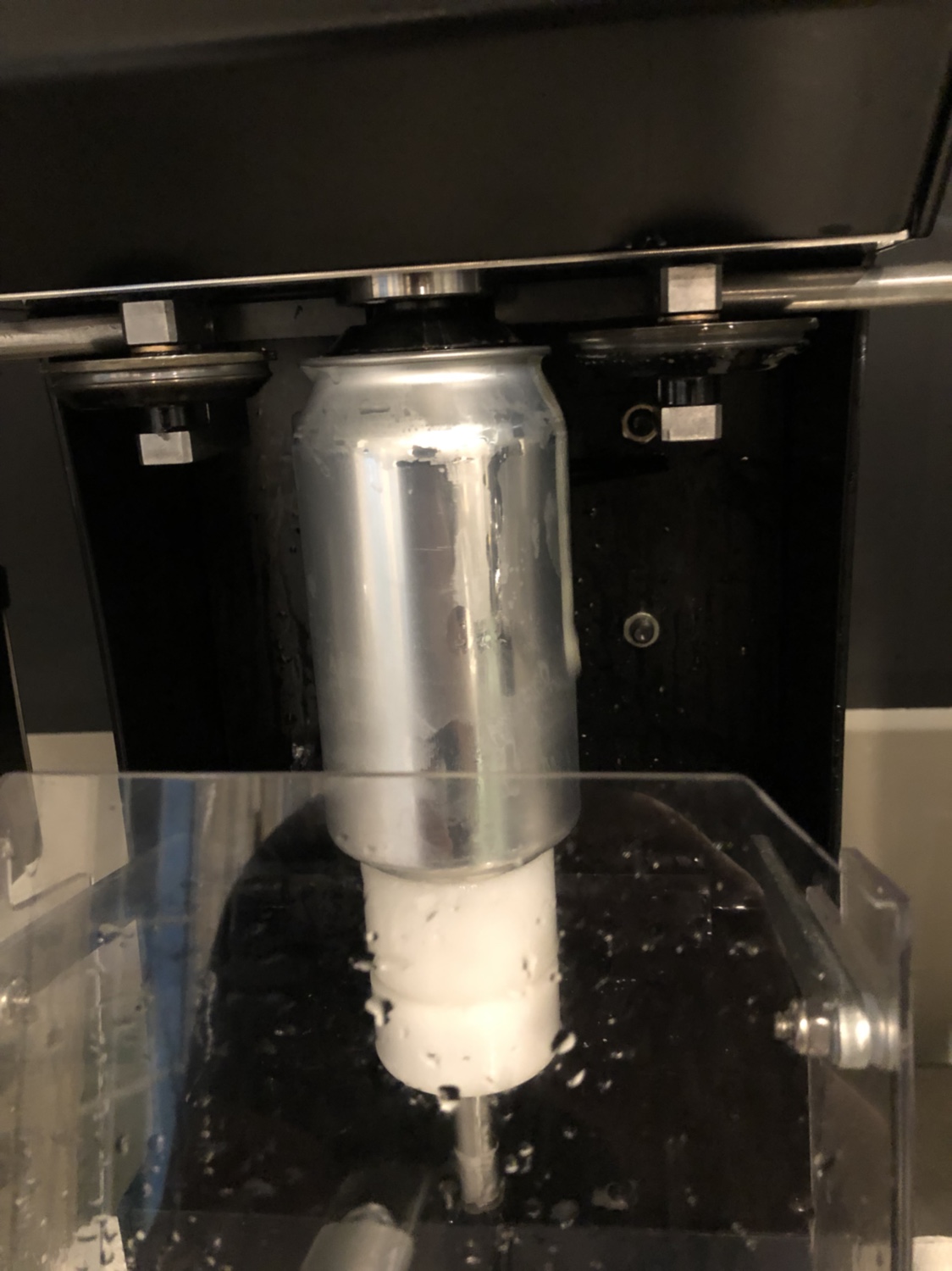

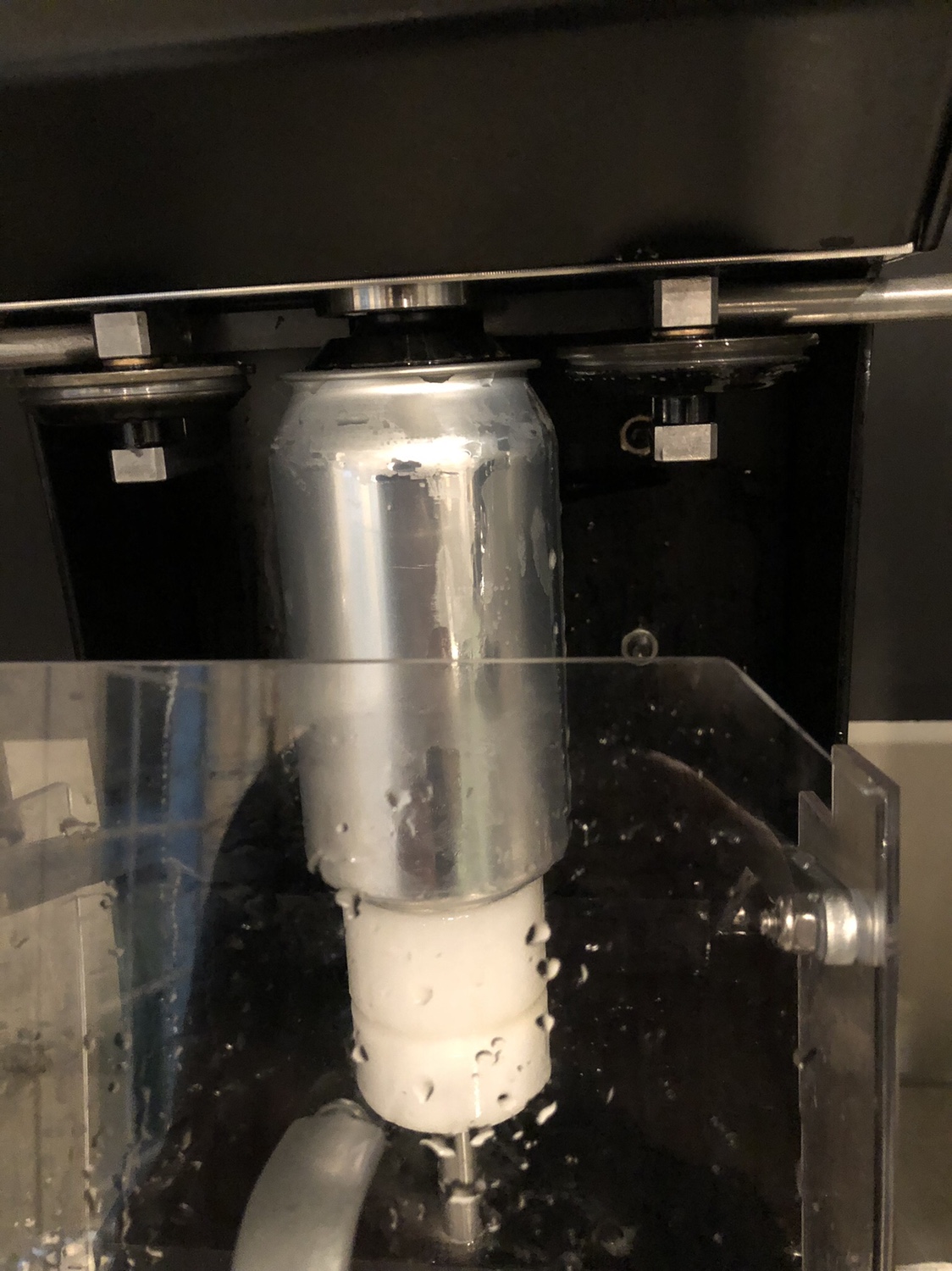

Anyone out there using an Oktober can seamer? I’m having significant oxidation issues with mine. Brewing mostly NEIPA’s right now. I do only closed transfers. I’m on a schedule where I will ferment for 12 days, cold crash for 2 (about 45f is the lowest I get with the More Beer conicals I have), pressure transfer to sanitized, pressurized kegs, carb with carb stone for about 3 or 4 hrs, then closed transfer to serving keg, and set at roughly 13psi for 5 to 7 days to finish carbing, and just batch age a bit. Beer has been coming out nice and bright, good aromatics, tastes great etc. Then I can... About 5 to 7 days later when I open a can, beer is darker, almost grayish tinged, and has an unmistakable off flavor. (This doesn’t happen to every can, but most of them) I’m using a beer gun to fill the cans right off the serving kegs (with psi turned down to 7 or so) purge each can with c02 for a full 10 seconds, fill so I displace a very small amt of beer when placing the cap on top of the can, and seam immediately. The seam itself on the can is totally fine. The only thing I can think of is maybe there is still a drop or 2 of sanitizer still in the can when I fill them, but I can’t imagine that would really do it.

Anyone have any thoughts on this?

Thanks!

Anyone have any thoughts on this?

Thanks!