MrEllis

Brewing Clueless

- Joined

- Jul 1, 2019

- Messages

- 24

- Reaction score

- 4

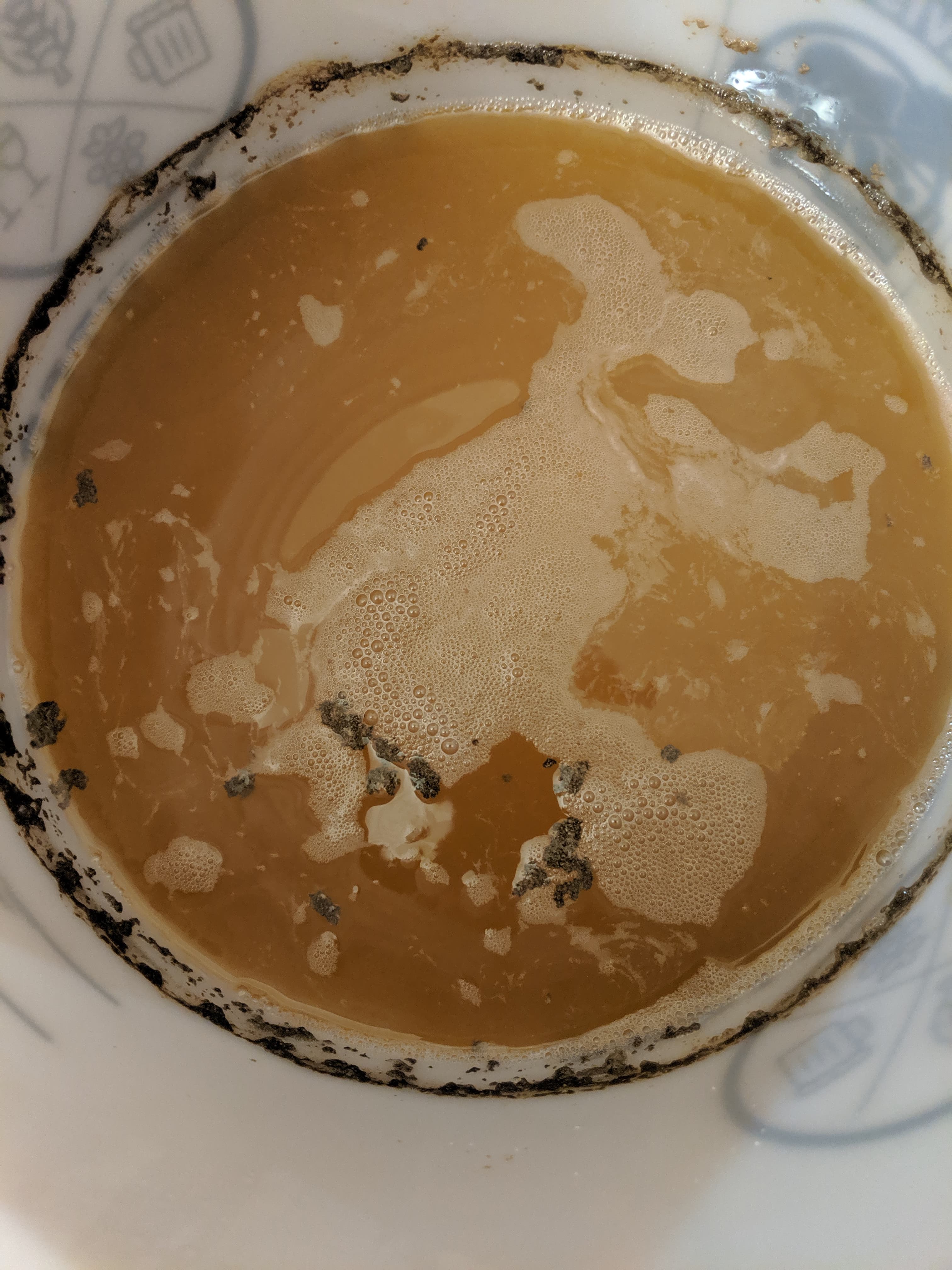

Okay, I have time and gear now. Doing a 3 gallon batch with five gallons of spring water on hand.

152-ish degrees for 60 minutes:

4 Pounds German Wheat Malt

2 Pounds German Pilsner

170-ish for 5 mins.

.75 Hallertau Mittelfruh for full 60 boil.

Sanitize gear with 1/4 oz Starsan to 2.5 gallons of water (I got spray bottles for it too).

Cool to 68ish and pitch.

About a week at 68 degrees (I don't have brew fridge yet next purchase) pray it's not a nanner bomb.

I plan to rack into a five gallon bucket with some dextrose and then immediately into 33 oz flip tops and allow it to carb for a few days at room temp.

What am I messing up?

152-ish degrees for 60 minutes:

4 Pounds German Wheat Malt

2 Pounds German Pilsner

170-ish for 5 mins.

.75 Hallertau Mittelfruh for full 60 boil.

Sanitize gear with 1/4 oz Starsan to 2.5 gallons of water (I got spray bottles for it too).

Cool to 68ish and pitch.

About a week at 68 degrees (I don't have brew fridge yet next purchase) pray it's not a nanner bomb.

I plan to rack into a five gallon bucket with some dextrose and then immediately into 33 oz flip tops and allow it to carb for a few days at room temp.

What am I messing up?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)