HopsAreGood

Well-Known Member

Mix one pack of verdant and one pack of New England. Pitch them at the same time. You can obviously adjust the amount of each based on your OG, but for beers north of 1.070 1 of each has worked great. I have two different beers in kegs right now where I did this and I love the results. I also have a third beer with the same combo finishing up fermentation right now. All three of them achieved ~ 80% apparent attenuation and the fermentations have been nearly identical in terms of time and behavior.Thoughts on Dry yeast alternatives for these types of styles?

I've just completed a hop hands with the new Mangrove jacks M66 Hophead.

1. Mangrove Jacks M66 hophead - good yeast, but not juicy, dropped clear, more APA/XPA than NEPA

2. Lallemand Verdant IPA - finished to sweet for me, but i had 5% carapils in the grist.

3. Lallemand New England - interesting, still not sold on the yeast in general, gives off big apple flavours, which im not a fan of.

4. S04 - I hate this yeast, so i didn't do so well with it.

5. Voss - Kveik is a good option, but gives a medium/high bright orange bitter pith note, which some don't like. needs to be carefully paired with hops.

6. Lallemand Belle Saison - Great option, did a 1.051 - 1.005 beer, with all mosaic, and its brilliant, funky, fruity, spicy and hoppy.

Keen to hear thoughts on some of the others below:

- Lallemand Nottingham

- Lallemand London

- any others.

Beer 1: 1.070 - 1.014 (80%)

Beer 2: 1.076 - 1.015 (80%)

Beer 3: 1.080 - currently at 1.018 but expecting it to finish around 1.016 for 80%.

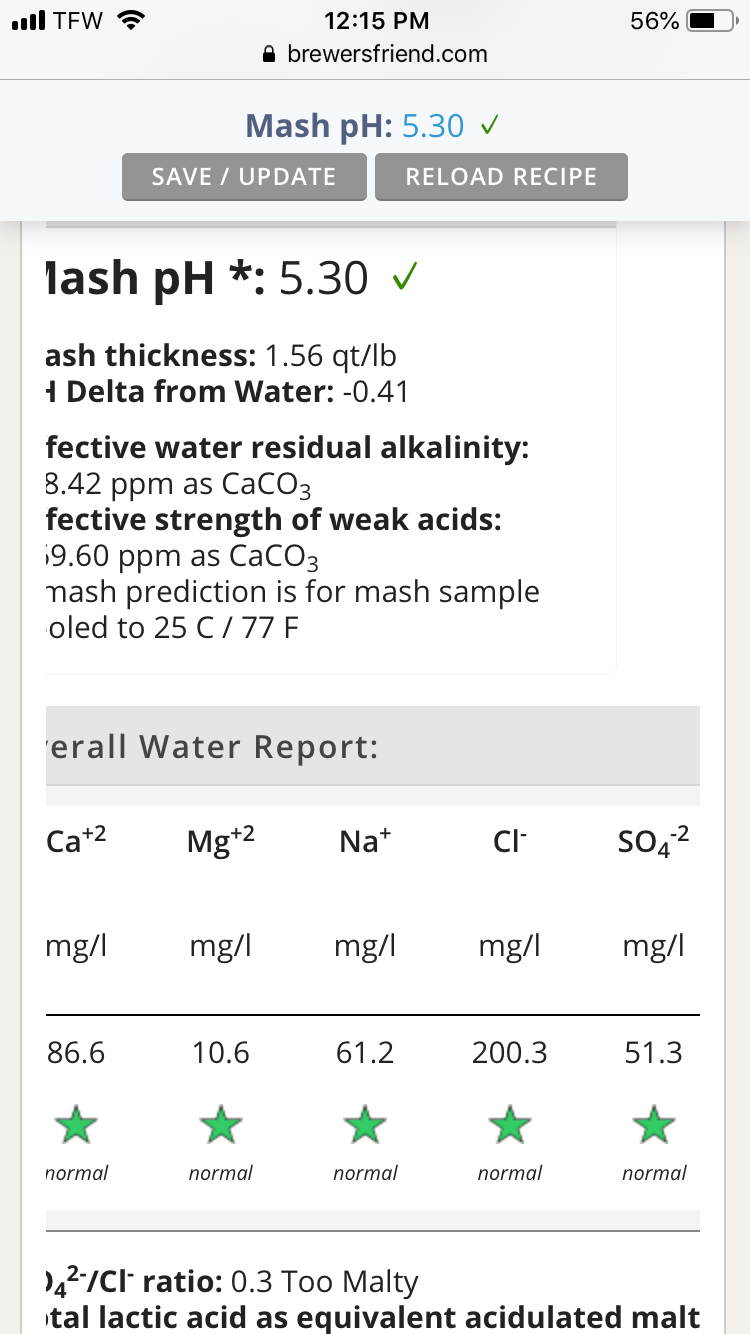

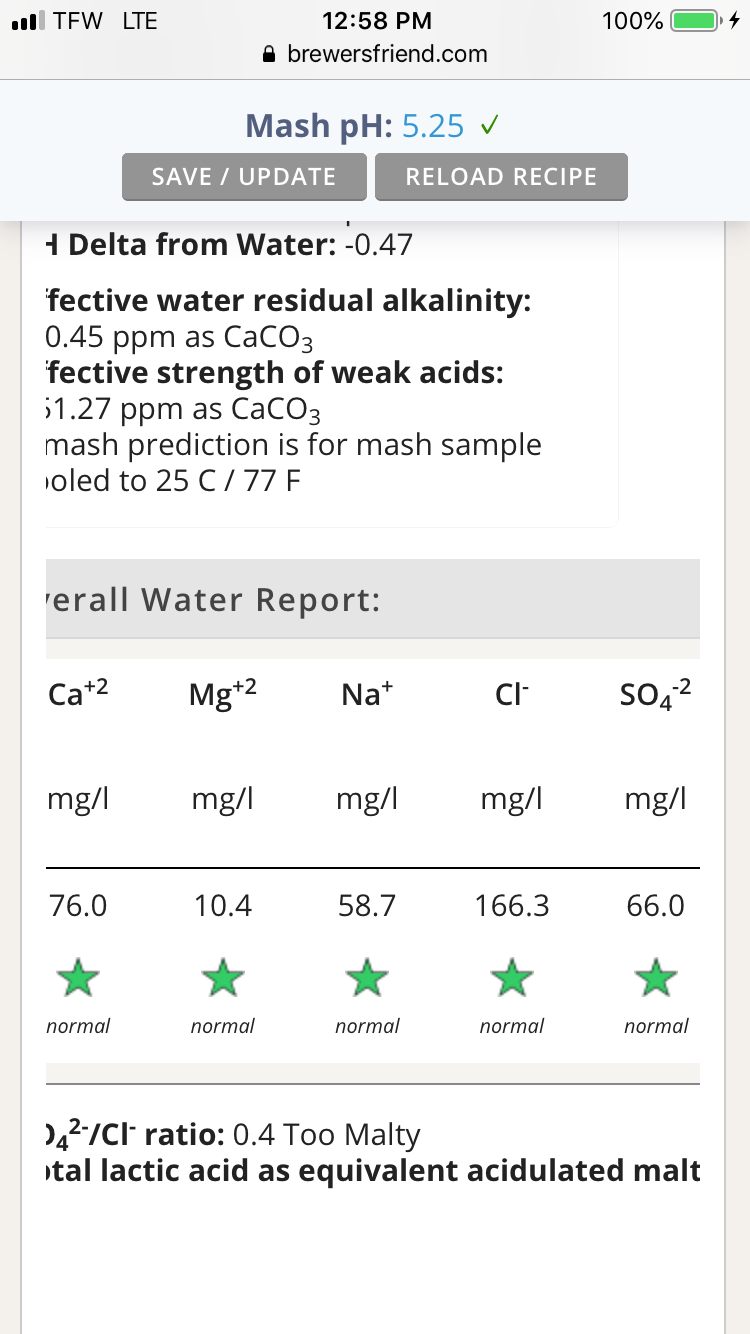

I should add that all three beers were mashed at 152 and each had one pound of dextrose added towards the end of the boil.

All three beers have been close to 90-95% finished at 72 hours post pitch. From 24-60 hours post pitch it is absolutely violent. The massive London 3/Verdant krausen appears on day three, and then typically fully falls bye the end of day five which is great. I’ve had plenty of LA3 krausens that never actually dropped, so maybe the Conan is coming into play here.

The finished beers are very soft but not sweet in any way. I did a few beers with only the verdant yeast, and while they were good they definitely had that vanilla/creamy/yogurt kind of thing going on that I didn’t really love. In combining these two yeast, at least for me, that character is completely gone. It just leaves a very nice, soft, round mouthfeel with some fruity esters.

I’d definitely recommend anyone looking for a new yeast or yeast combination to give it a try.

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)