Glad to hear that as I would have wagered there was something amiss from that picture you posted!Never mind. All is well. View attachment 583187

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New England IPA "Northeast" style IPA

- Thread starter Braufessor

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ca_baracus

Well-Known Member

- Joined

- Jun 15, 2017

- Messages

- 109

- Reaction score

- 25

Glad to hear that as I would have wagered there was something amiss from that picture you posted!

Oh yeah? What was your initial thought?

Well I had initially thought some wild yeast contamination. To me the photo resembled many of the sour beer fermentation pictures that have been posted. Yours didn't look quite this bad.Oh yeah? What was your initial thought?

popquizkid

Well-Known Member

- Joined

- Oct 29, 2013

- Messages

- 216

- Reaction score

- 89

Lastest NEIPA. My 1st try a few days ago disappointed me. 1 week bottled now and no diacetyl nor oxygenation. Not a substantial amount of flavor but ill take it. Left is a Pinthouse Pizza DIPA. Right is mine.

View attachment 582967

Like the Rhinegeist glass!

milldoggy

Well-Known Member

Here is my most recent

5# Marris Otter

14.5# Golden Promise

.5# Acid Malt

2# Carapils

3# Wheat

2# Flaked Wheat

1# Lactose

2 oz Columbus - FWH

1 oz Columbus - 5 min

2 oz El Dorado - 5 min

2 oz Comet - 5 min

2 oz Columbus - @180 whirlpool 30 min

2 oz El Dorado - @180 whirlpool 30 min

2 oz Comet - @180 whirlpool 30 min

2 oz Columbus - @160 whirlpool 30 min

2 oz El Dorado - @160 whirlpool 30 min

2 oz Comet - @160 whirlpool 30 min

One keg

1 oz Simcoe lulpin powder

2 oz Simcoe

OG was 1.058

FG was 1.010

Yeast was Conan, but added a package of 2 year old dry BE-256(which had the old name of abbaya on it)

Kegging now, taste amazing,

5# Marris Otter

14.5# Golden Promise

.5# Acid Malt

2# Carapils

3# Wheat

2# Flaked Wheat

1# Lactose

2 oz Columbus - FWH

1 oz Columbus - 5 min

2 oz El Dorado - 5 min

2 oz Comet - 5 min

2 oz Columbus - @180 whirlpool 30 min

2 oz El Dorado - @180 whirlpool 30 min

2 oz Comet - @180 whirlpool 30 min

2 oz Columbus - @160 whirlpool 30 min

2 oz El Dorado - @160 whirlpool 30 min

2 oz Comet - @160 whirlpool 30 min

One keg

1 oz Simcoe lulpin powder

2 oz Simcoe

OG was 1.058

FG was 1.010

Yeast was Conan, but added a package of 2 year old dry BE-256(which had the old name of abbaya on it)

Kegging now, taste amazing,

Last edited:

Sorry for the absence. It has been hectic with life around my house.Primary to

Secondary to

Bottling Bucket to

Bottle.......

I would try to cut that down if you feel you can.

I would either go primary to bottle

or

Primary to bottling bucket to bottle

Less transferring the better for a beer like this.

I got the beer bottled. I ended up going:

Primary to

Bottling bucket to

Bottle.

I used 'Grolsch' style bottles with the bails. That went quite well.

When I transferred to the bottling bucket, the amount of hops in the bottom of the primary fermenting bucket was crazy. I can imagine there is some sort of work around to this but I am not aware of it yet. I estimate about 5 liters loss total, which I find quite high, but I have no frame of reference so that could be normal.

I bought some drops to carbonate, that was super easy. I may use these more often!

I purged the bottles with some co2 gas I found in a nifty can made for wine drinkers, that was also pretty cool. The filling went smoothly too.

The hop aroma was out of this world! The room really became saturated with the hops from the beer. It should be carbonated up soon and I will be able to try it out. I have an idea what I am going for in terms of flavor so hopefully this puts me in the right direction.

I will be sure to report back with a tasting and glass photo. I am not planning on brewing again until late September, when the temperatures drop back down again. It has been crazy hot in Switzerland, one of the hottest summers in the last 11 years. My normally stable cellar temperature even raised up 3 degrees.

The next time I am going to try using cryo hops to cut down on waste and look into using something to see if I can further reduce waste. I ended up with about 15 usable liters, which translated to roughly 46 33cl bottles of beer. the plan is to split it three ways with my partners.

I also have some money earmarked for gear purchases too. new boil kettles and a conical fermenter.

A big, big thanks to everyone who helped me through this! Onward and upward!

Last edited:

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

Hopping4Hops

Active Member

- Joined

- Feb 22, 2018

- Messages

- 32

- Reaction score

- 5

Sorry for the absence. It has been hectic with life around my house.

...

A big, big thanks to everyone who helped me through this! Onward and upward!

Cold crashing will compact the trub so you leave less beer behind. What I do to package every single drop is after bottling what I can, I drop what's left in the bucket in a 300 micron bag and squeeze the juice out of it. Then I package it to a 2L soda bottle which I squeeze while screwing the cap to eliminate all the air. I find the beer I get from that to be the best of the batch. Probably because squeezing on the hops releases every last aromatic oil that didn't get to the beer and although O2 is introduced with the process, the yeast is fast to eat it up while conditioning and there is no extra in the headspace keeping the beer protected. I usually open this about a month later, after I have drunk all the bottles and still it has the most saturated aroma.

Last edited:

stickyfinger

Well-Known Member

Sorry for the absence. It has been hectic with life around my house.

I got the beer bottled. I ended up going:

Primary to

Bottling bucket to

Bottle.

I used 'Grolsch' style bottles with the bails. That went quite well.

When I transferred to the bottling bucket, the amount of hops in the bottom of the primary fermenting bucket was crazy. I can imagine there is some sort of work around to this but I am not aware of it yet. I estimate about 5 liters loss total, which I find quite high, but I have no frame of reference so that could be normal.

I bought some drops to carbonate, that was super easy. I may use these more often!

I purged the bottles with some co2 gas I found in a nifty can made for wine drinkers, that was also pretty cool. The filling went smoothly too.

The hop aroma was out of this world! The room really became saturated with the hops form the beer. It should be carbonated up soon and I will be able to try it out. I have an idea what I am going for in terms of flavor so hopefully this puts me in the right direction.

I will be sure to report back with a tasting and glass photo. I am not planning on brewing again until late September, when the temperatures drop back down again. It has been crazy hot in Switzerland, one of the hottest summers in the last 11 years. My normally stable cellar temperature even raised up 3 degrees.

The next time I am going to try using cryo hops to cut down on waste and look into using something to see if I can further reduce waste. I ended up with about 15 usable liters, which translated to roughly 46 33cl bottles of beer. the plan is to split it three ways with my partners.

I also have some money earmarked for gear purchases too. new boil kettles and a conical fermenter.

A big, big thanks to everyone who helped me through this! Onward and upward!

just make a little extra wort so you get more packaged

Cold crashing will compact the trub so you leave less beer behind.

THIS ^^^

Since I started cold crashing my IPAs, the trub is very compact at the bottom of the fermentor. And by tipping my primary (Better Bottle) I can get all but a few ounces into my keg or bottling bucket. Even the action of tipping washes very little trub up from the bottom and up into the siphon. Also, I have at times clamped a paint strainer bag onto the end of my siphon tube in the bottom of the bucket to catch what does slip past. But honestly, it's pretty minimal after a cold crash.

ca_baracus

Well-Known Member

- Joined

- Jun 15, 2017

- Messages

- 109

- Reaction score

- 25

What's your process for cold crashing (temp, time, airlock, etc.)? I haven't read much into it, but from what I have seen, people are concerned about suck back. I haven't been able to get a full 5 gal in my corny keg with my last two NEIPA's because of all the trub.THIS ^^^

Since I started cold crashing my IPAs, the trub is very compact at the bottom of the fermentor. And by tipping my primary (Better Bottle) I can get all but a few ounces into my keg or bottling bucket. Even the action of tipping washes very little trub up from the bottom and up into the siphon. Also, I have at times clamped a paint strainer bag onto the end of my siphon tube in the bottom of the bucket to catch what does slip past. But honestly, it's pretty minimal after a cold crash.

Thanks all for the replies. I would also like to know your process for old crashing. The way I understand it, you cool the beer to near freezing temperatures using some sort of cooling device.

Thanks all for the replies. I would also like to know your process for old crashing. The way I understand it, you cool the beer to near freezing temperatures using some sort of cooling device.

What's your process for cold crashing (temp, time, airlock, etc.)? I haven't read much into it, but from what I have seen, people are concerned about suck back. I haven't been able to get a full 5 gal in my corny keg with my last two NEIPA's because of all the trub.

I just recently bought a two tap kegerator (converted mini fridge) and since it was empty my 7 gal Better Bottle easily fit inside. Now that I have a corny in there, I need to check to see if both will fit at the same time. Previously I just rearranged my beer fridge in the garage and removed one half width shelf so the carboy would fit.

Regarding suck-back: I use vodka rather than Starsan in my airlock, so I don't worry if a little gets sucked in. Even Starsan supposedly wouldn't hurt anything. Another option would be to remove the airlock and just cover the hole with sanitized foil. I dunno - I feel better if any air that's sucked in has to pass through the vodka first.

As far as time: I do 24 hours. That's long enough to drop the beer temp into the upper 40s, which is good enough for me. I've read that crashing longer and to a lower temp doesn't really have any advantages. Yeah, when I get a jacketed SS fermentor with glycol cooling, I'll probably crash to the upper 30s, but who knows when that will happen...

I wouldn't recommend sucking vodka or Star san into your beer... especially in this style.

Blow up a balloon with CO2 and attach it to your airlock or try one of these nifty new gadgets from brewhardware

https://www.brewhardware.com/product_p/ccguardianv2.htm

Or just crash it in the keg

Blow up a balloon with CO2 and attach it to your airlock or try one of these nifty new gadgets from brewhardware

https://www.brewhardware.com/product_p/ccguardianv2.htm

Or just crash it in the keg

I cold crash only to get the hops to drop to the bottom. Usually by the time its get to 50f they have dropped. Beginning the process I use one of those flimsy plastic bags that are available in the produce sections of grocery stores, I use unused ones. A rubber band is used to secure a 3" length of 3/8 hose to it, then I blow it up with CO2. I hold my finger over the end then pull my 1/2" blowoff tube out of the starsan container and fit it over the tube on the bag. This is all done prior to dropping the temperature. The bag/balloon rarely completely deflates and no O2 gets in during crashing.I wouldn't recommend sucking vodka or Star san into your beer... especially in this style.

Blow up a balloon with CO2 and attach it to your airlock or try one of these nifty new gadgets from brewhardware

https://www.brewhardware.com/product_p/ccguardianv2.htm

Or just crash it in the keg

Regarding suck-back: I use vodka rather than Starsan in my airlock, so I don't worry if a little gets sucked in. Even Starsan supposedly wouldn't hurt anything. Another option would be to remove the airlock and just cover the hole with sanitized foil. I dunno - I feel better if any air that's sucked in has to pass through the vodka first.

The concern with suck-back isn't the 1/2 oz of sanitizer, its the quarts of O2.

Blow up a balloon with CO2 and attach it to your airlock or try one of these nifty new gadgets from brewhardware

https://www.brewhardware.com/product_p/ccguardianv2.htm

Whoa, that's pretty cool. I had made something similar but this is much higher quality.

A change from 70F to 50F is only a .15% change in volume. That doesn't equate to quarts of air. Regardless, I added a port to hook up to CO2 during the cold crash process.

Pinthouse Pizza Electric Jellyfish clone V1 going.

Pinthouse Pizza Electric Jellyfish clone V1 going.

A change from 70F to 50F is only a .15% change in volume. That doesn't equate to quarts of air. Regardless, I added a port to hook up to CO2 during the cold crash process.

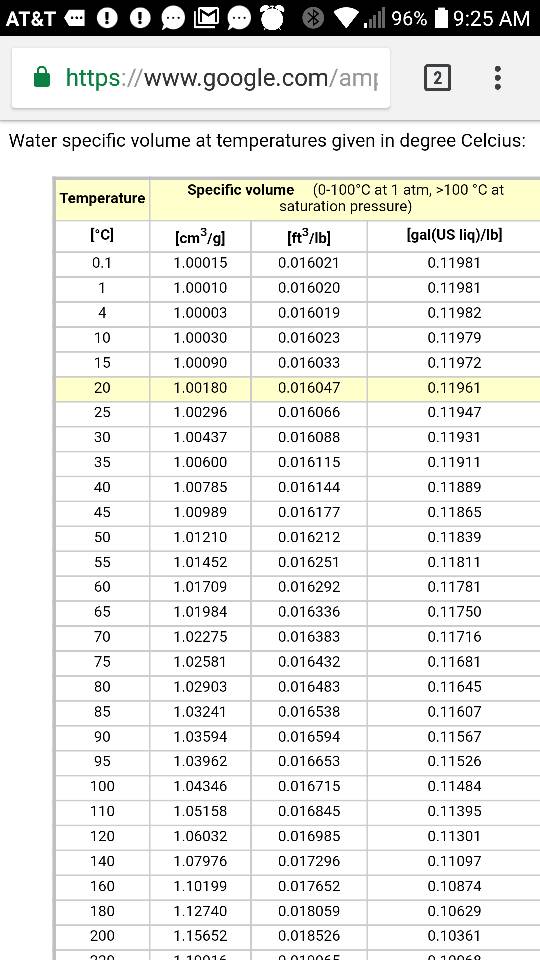

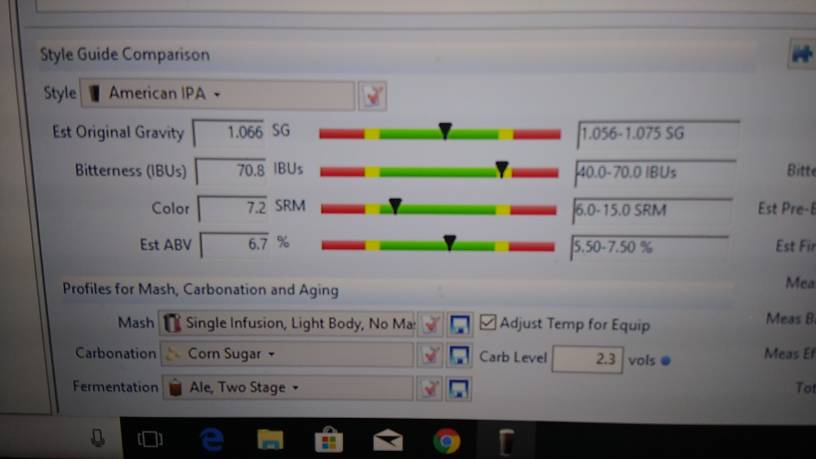

Pinthouse Pizza Electric Jellyfish clone V1 going.View attachment 584776View attachment 584777

But that's only part of the equation.

This post is gold. It was in response to me expressing skepticism about the oxidation from cold crashing being significant.

So if you've got 1-2 gallons of headspace, you're looking at 2-4 quarts of air.https://www.homebrewtalk.com/forum/threads/cold-crashing-and-oxidation.584234/#post-7591941

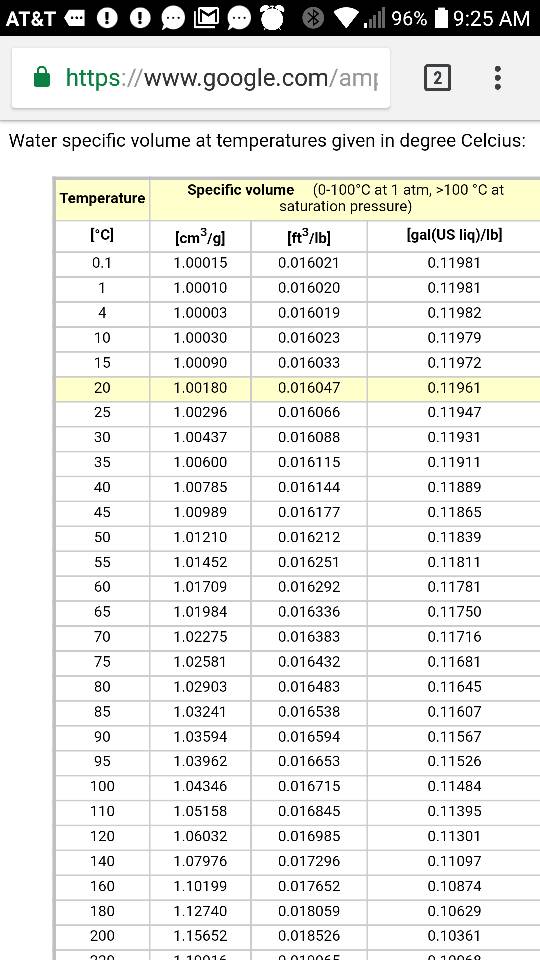

I did some calculations a while back for a 24 liter (6.4 gal) fermenter with 20 liters (5.3 gal) of beer and 4 liters (1.1 gal) of headspace. At the end of fermentation, the headspace is 100% CO2 at an absolute pressure of 14.7 psi. If the fermentation temp was 18˚C (64.4˚F) and you cold crash to 1˚C (33.8˚F), then the CO2 partial pressure drops from 14.7 psi to 13.8 psi. Due to the drop in CO2 pressure, 0.9 psi worth of air will suck back into the headspace, and the headspace will then contain 0.9 / 14.7 = 6% air and 1.2% O2 (about 12,000 ppm O2.)

Now since you cooled the beer, it will absorb more CO2 from the headspace. When equilibrium is reached, the CO2 partial pressure in the headspace will be 8.0 psi, and enough more air needs to suck back to make the air partial pressure 14.7 - 8.0 = 6.7 psi. The percentage of air in the headspace will then be 6.7 / 14.7 = 45.6%, and the O2 percentage will be 9.6% (about 96,000 ppm.)

So, immediately after cold crashing you will have about 12,000 ppm O2 in the headspace, which is more than enough to oxidize the beer over time. As cold crashing continues, the O2 concentration will rise towards 96,000 ppm. And, as the O2 concentration rises, the rate of absorption of O2 into the beer will increase, allowing for even faster oxidation of the beer.

I don't have data on how fast O2 absorbs into the beer, nor how fast the actual beer oxidation occurs at cold crash temps. The only advice I can offer is to keep your cold crash time to the absolute minimum, and also minimize any agitation of the beer which could cause additional O2 absorption.

Brew on

I just ordered two of these from Bobby, which seem like a simple and cheap solution: https://www.brewhardware.com/product_p/ccguardianv2.htm

LoneTreeFarms

Well-Known Member

A change from 70F to 50F is only a .15% change in volume. That doesn't equate to quarts of air. Regardless, I added a port to hook up to CO2 during the cold crash process.

Pinthouse Pizza Electric Jellyfish clone V1 going.View attachment 584776View attachment 584777

Need this recipe! ^^^

But that's only part of the equation.

What's the other part? In a 5gal batch .15% is equivalent to removing 1oz of liquid. I still dont think that equals quarts of air.

And give me a couple hours LonePint...I'll post it here. Remember version 1..

What's the other part? In a 5gal batch .15% is equivalent to removing 1oz of liquid. I still dont think that equals quarts of air.

Sorry if that wasn't clear. The post below the

is something I copied here that doug293cz posted in another thread. That explains the other part. The shrinking beer is a minor consideration compared to the shrinking co2 in the head space and the increased capacity of the cold beer to absorb co2.

is something I copied here that doug293cz posted in another thread. That explains the other part. The shrinking beer is a minor consideration compared to the shrinking co2 in the head space and the increased capacity of the cold beer to absorb co2.My PM version. For dry hopping 3/4 at day 3 fermentaion and 1/4 keg hops.Need this recipe! ^^^

thirstypanda

Member

But that's only part of the equation.

This post is gold. It was in response to me expressing skepticism about the oxidation from cold crashing being significant.

So if you've got 1-2 gallons of headspace, you're looking at 2-4 quarts of air.

I just ordered two of these from Bobby, which seem like a simple and cheap solution: https://www.brewhardware.com/product_p/ccguardianv2.htm

Interesting... however, since co2 has a molar mass of 44g versus 33g for o2, would the o2 not rise above and the co2 protect the beer?

Back to the recipe, I'm going to wet hop this recipe with a bit of Magnum from my garden for bittering, Cascade + Centennial (local farm has this available real cheap) in whirlpool, and for "dry" hopping. Plus I'm going to add a pound of rye malt I've got kicking around.

Thoughts?

CO2 and O2 will not stratify by weight.... they continue to mix and move as particles. I suppose if you could get them cold enough and still enough..... maybe.... but, that is not what we are dealing with in brewing.

Ultimately folks who focus on oxygen and its effects are correct. Oxygen WILL be a problem for beer. It does not take a lot. There are points of entry for oxygen all over the place and it takes some real planning to eliminate them.... if they can ever actually be totally eliminated at all.

That said...... practically speaking.....

More oxygen is bad and less oxygen is better and will make a difference even if you are not eliminating 'all" oxygen.

Do the things you can do, the things you are comfortable doing and the things you want to do. Any steps you take along the way will help a beer like this as you implement them into the process you have.

I try to implement a number of precautions, but would never claim to conquer every point of entry....... you can definitely make very good beer with some relatively simple and easily executed adjustments to the process.

Ultimately folks who focus on oxygen and its effects are correct. Oxygen WILL be a problem for beer. It does not take a lot. There are points of entry for oxygen all over the place and it takes some real planning to eliminate them.... if they can ever actually be totally eliminated at all.

That said...... practically speaking.....

More oxygen is bad and less oxygen is better and will make a difference even if you are not eliminating 'all" oxygen.

Do the things you can do, the things you are comfortable doing and the things you want to do. Any steps you take along the way will help a beer like this as you implement them into the process you have.

I try to implement a number of precautions, but would never claim to conquer every point of entry....... you can definitely make very good beer with some relatively simple and easily executed adjustments to the process.

MistaCitra

Active Member

- Joined

- Nov 22, 2017

- Messages

- 35

- Reaction score

- 4

If I was your mail man, that would have been taxed.

Crusher is delectable

MistaCitra

Active Member

- Joined

- Nov 22, 2017

- Messages

- 35

- Reaction score

- 4

Just kegged my second NEIPA batch last night and saw this:

View attachment 582994

I dry hopped during high krausen (48hrs after pitching). I'm thinking (hoping) that it was just krausen/foam stuck on the dry hops that never dropped out. Beer smells and tastes great, so I don't think it's an infection. Anyone else run into this?

Lol looks like it was good

ca_baracus

Well-Known Member

- Joined

- Jun 15, 2017

- Messages

- 109

- Reaction score

- 25

Best batch I've brewed yet.Lol looks like it was good

Veidog

Member

- Joined

- Sep 19, 2013

- Messages

- 10

- Reaction score

- 1

This is my 3rd time brewing this recipe. I just added my dry hop on day 3, without bagging it. What's the best way to transfer to keg after it's done fermenting? I'm using the fast fermenter. Any tips to filter out the hops during transfer? Thanks in advance.

milldoggy

Well-Known Member

Crusher is one of my favs.Crusher is delectable

A change from 70F to 50F is only a .15% change in volume. That doesn't equate to quarts of air. Regardless, I added a port to hook up to CO2 during the cold crash process.

Pinthouse Pizza Electric Jellyfish clone V1 going.View attachment 584776View attachment 584777

Especially when using a leaky sealed bucket, you have to be super careful to set your CO2 pressure above zero but below the pressure which will leak out of the lid seal otherwise you can be down a pound of CO2 or more by the time you cold crash.

For a data point, when I cold crash a typical 6 gallon batch in a 7.25g fermonster, it draws in about 1.5 quarts (eyeballed) from 65f to 35f. I'd love to refer to a formula that accounts for it, across both the liquid and headspace, but it's just easier to tell you to trust me as I've observed it at least 10 times in a row recently.

I just hooked up my new cold crash guardian today! Thanks Bobby!Especially when using a leaky sealed bucket, you have to be super careful to set your CO2 pressure above zero but below the pressure which will leak out of the lid seal otherwise you can be down a pound of CO2 or more by the time you cold crash.

For a data point, when I cold crash a typical 6 gallon batch in a 7.25g fermonster, it draws in about 1.5 quarts (eyeballed) from 65f to 35f. I'd love to refer to a formula that accounts for it, across both the liquid and headspace, but it's just easier to tell you to trust me as I've observed it at least 10 times in a row recently.

https://www.brewhardware.com/product_p/ccguardianv2.htm

ca_baracus

Well-Known Member

- Joined

- Jun 15, 2017

- Messages

- 109

- Reaction score

- 25

Interesting! Let us know how it works for you.I just hooked up my new cold crash guardian today! Thanks Bobby!

https://www.brewhardware.com/product_p/ccguardianv2.htm

Northern_Brewer

British - apparently some US company stole my name

I don't think this has been mentioned here before : www.hopsteiner.com/blog/blending-hops-to-match-target-hop-profile/

It's research at Campden BRI funded by Hopsteiner, looking to blend Hopsteiner hops to replicate some of the big name hops. It only had 10 people on the testing panel so you can take their claims of no significant differences with a pinch of salt. Anyway, in summary :

Amarillo late kettle - 5:1 Cascade:Lemondrop

Citra dry hop - 70/30 Calypso/Bravo (40/35/35 Eureka/Calypso/Apollo was tested but was rejected)

Simcoe dry hop - 50/40/10 Eureka/Apollo/Cascade (60/40 Eureka/Calypso rejected)

Looking at their spidergrams, 60/40 Eureka/Apollo looks a pretty close shout for Citra, and I wonder if something like 2:1 Eureka/Chinook might not be even closer. Eureka is the only one of theirs that gives that tropical element, so it has to figure quite highly.

Even if they're not a perfect match for Citra etc, these blends can still make for interesting beer in their own right, and it's certainly less painful paying 2/3 the price of Citra at the hopping rates that are now fashionable!

Something else that came out of their initial research, on Amarillo - hop teas are a lousy way to assess hop flavour, there's a whole load of vegetal flavours that aren't present in beer.

It's research at Campden BRI funded by Hopsteiner, looking to blend Hopsteiner hops to replicate some of the big name hops. It only had 10 people on the testing panel so you can take their claims of no significant differences with a pinch of salt. Anyway, in summary :

Amarillo late kettle - 5:1 Cascade:Lemondrop

Citra dry hop - 70/30 Calypso/Bravo (40/35/35 Eureka/Calypso/Apollo was tested but was rejected)

Simcoe dry hop - 50/40/10 Eureka/Apollo/Cascade (60/40 Eureka/Calypso rejected)

Looking at their spidergrams, 60/40 Eureka/Apollo looks a pretty close shout for Citra, and I wonder if something like 2:1 Eureka/Chinook might not be even closer. Eureka is the only one of theirs that gives that tropical element, so it has to figure quite highly.

Even if they're not a perfect match for Citra etc, these blends can still make for interesting beer in their own right, and it's certainly less painful paying 2/3 the price of Citra at the hopping rates that are now fashionable!

Something else that came out of their initial research, on Amarillo - hop teas are a lousy way to assess hop flavour, there's a whole load of vegetal flavours that aren't present in beer.

Last edited:

Lastest NEIPA. My 1st try a few days ago disappointed me. 1 week bottled now and no diacetyl nor oxygenation. Not a substantial amount of flavor but ill take it. Left is a Pinthouse Pizza DIPA. Right is mine.

[ATTACH

My PM version. For dry hopping 3/4 at day 3 fermentaion and 1/4 keg hops. View attachment 584808View attachment 584809

Hey PM, how did you come up with the Electric Jellyfish recipe? I was in Austin last weekend and stopped in to get a crowler. Haven't had it for a couple of years so looking forward to cracking open that bad boy soon. Have you been to Hi Sign yet? Their Hi-C NEIPA was pretty solid. Especially the aroma which may have been better than the taste.

If you haven't had EJ for a couple years and if the batch is fresh, get ready to be Wow'ed! They've modified the recipe, incorporated lupilin powder and have it down now. Good tasting!Hey PM, how did you come up with the Electric Jellyfish recipe? I was in Austin last weekend and stopped in to get a crowler. Haven't had it for a couple of years so looking forward to cracking open that bad boy soon. Have you been to Hi Sign yet? Their Hi-C NEIPA was pretty solid. Especially the aroma which may have been better than the taste.

Let me first say this recipe is no Jellyfish and not drinkable right now. It's like hop oil syrup right now. No go, unless you like the enamel removed off your teeth...[emoji39]

Coming up with recipe was a combination of articles, PhP website, best practices, and known targets. I've never used that much Cryo Hops and never in boil so was a 100% experiment anyway. See what happens in a week or so but clearly needs adjusting. No boil hops at all next time. Probably halfing dry hops. More Citra for sure. Also, supposedly theres Calypso which I didnt add.

Last edited by a moderator:

stickyfinger

Well-Known Member

1 gallon of crap at the bottom is normal for a hop bomb beer. don't worry about it.

Sorry for the absence. It has been hectic with life around my house.

I got the beer bottled. I ended up going:

Primary to

Bottling bucket to

Bottle.

I used 'Grolsch' style bottles with the bails. That went quite well.

When I transferred to the bottling bucket, the amount of hops in the bottom of the primary fermenting bucket was crazy. I can imagine there is some sort of work around to this but I am not aware of it yet. I estimate about 5 liters loss total, which I find quite high, but I have no frame of reference so that could be normal.

I bought some drops to carbonate, that was super easy. I may use these more often!

I purged the bottles with some co2 gas I found in a nifty can made for wine drinkers, that was also pretty cool. The filling went smoothly too.

The hop aroma was out of this world! The room really became saturated with the hops from the beer. It should be carbonated up soon and I will be able to try it out. I have an idea what I am going for in terms of flavor so hopefully this puts me in the right direction.

I will be sure to report back with a tasting and glass photo. I am not planning on brewing again until late September, when the temperatures drop back down again. It has been crazy hot in Switzerland, one of the hottest summers in the last 11 years. My normally stable cellar temperature even raised up 3 degrees.

The next time I am going to try using cryo hops to cut down on waste and look into using something to see if I can further reduce waste. I ended up with about 15 usable liters, which translated to roughly 46 33cl bottles of beer. the plan is to split it three ways with my partners.

I also have some money earmarked for gear purchases too. new boil kettles and a conical fermenter.

A big, big thanks to everyone who helped me through this! Onward and upward!

Not groundbreaking but worth mentioning... I ferment in a keg. I have 5 and 10 gallon cornies that I use depending on batch size. Most of us have extra kegs available to use for this purpose and as Andy told Red, “if you’ve come this far, maybe you’re willing to come a little further.” The kegs are outfitted with floating dip tubes from Clear Beer Draught System. Leaving about 0.5 gallons in headspace, primary is initiated with a lid modified to fit a blowoff tube (photo attached).

After blowoff subsides and the krausen begins to fall (usually after day 3 or 4 with 1318), the beer is dry-hopped and fitted with a standard lid, purged with CO2 and a blowoff is attached to a gas QD (photo attached). The beer then finishes out primary for as long as needed and is then put directly in the kegerator to both cold crash and carb for at least a week. No transfer to a serving keg is necessary with this setup and this particular style.

It’s simple and doesn’t require much fuss at all. And the beer comes out tasting very good!

Burndog

Well-Known Member

great recipe... Only thing I notice is the "head" does not last... Been sitting on 12psi for the past couple weeks and produces a full head on each pour but quickly diminishes.

Anyone else seeing this?

Anyone else seeing this?

Depends on how quick your quickly is. Mine is mostly gone after drinking 2/3rds of the pint so maybe 3-4 minutes? No proven idea how to extend it.great recipe... Only thing I notice is the "head" does not last... Been sitting on 12psi for the past couple weeks and produces a full head on each pour but quickly diminishes.

Anyone else seeing this?