SookeBrewing

Well-Known Member

Hey gang - I'm working on a PROJECT!

I've finally gotten to a point in my build that I have some pictures of stuff that I want to share. When we bought this house about 2 years ago, I knew that it was PERFECT for a larger, purpose-built brewery. I discovered TheElectricBrewery.com some time last year and have been salivating over it ever since.

Right now, I brew using some pretty basic equipment - a turkey fryer burner, big-ass aluminum pot and a cooler mash tun with stainless braid. I'm lucky enough to have gotten a free 100lb propane tank, and my equipment fits nicely in my well house, which, obviously, has a readily available source of water (its foundation is a 2500gal concrete cistern). The room is also small enough and very well insulated (to prevent freezing) that it works well as a fermentation room since there is already a heater in there (needed in the winter but not the summer, of course).

This is the new home of brewery 2.0, tentatively called "North Wall Brewing," since it occupies the north wall of my garage.

When we bought the place, the garage was neither insulated nor heated, so temperature swings are pretty wild in all seasons, especially the late spring and early fall when it's chilly at night and warm in the day. First order of business was to insulate and put up some walls:

We had an electrician run the lines for the heat before we did this. Due to a very, very busy summer I didn't have as much time as I'd liked to work on it, but finally managed to get the last of the OSB up a few days ago. This is the area NWB will occupy:

SWMBO wanted a ping pong table. She's better than I.

When I first thought about building the brewery, I assumed I'd be able to use this existing 220V outlet, but as you can see, it is a welding-type one that is only good for that purpose, something I learned from reading this and other forums and sites, thanks! Thankfully, I realized this before I put up the walls in the garage in that spot.

So I installed a new dryer outlet with the proper 30A 4-wire cabling, and ran it back to my panel where it now sits, waiting for a very expensive GFI breaker (at least $250) :-(

I got to work building the brew stand. First, I built a larger, modified version of it as my general-purpose work bench. A little higher, with a plywood top, and no bottom shelf, 8 feet long. Once that was done, I set to work on my stand. I'm really happy with the way it turned out.

Both stands, before sanding and staining:

I finished staining them last night, and I love the results. I used Minwax stain, Early American colour. We had cabinets with this stain at our last house. I love it.

I got that laundry sink for free - it's nearly brand-new. Since I'll really only be draining water and yeasties and non-toxic cleaning stuff, I'm going to run the drain for this either out the door into the grass, or through the wall and to a conveniently-located perimeter drain cleanout which drains the rainwater to a ditch below my property (probably the latter).

I got my hands on 3 used Sanke kegs, so I couldn't pass up the opportunity to convert them and save some major bucks on this build. I guess I can always upgrade later. I cut the tops off them and I'll be ordering fittings soon. I will also be shining them up like a boss.

In the left of the following photo, you can see my 1" water line that will be connected soon - then I will run 1/2" pex to the sink and create connections for the HLT and chiller. Just cold water, for now.

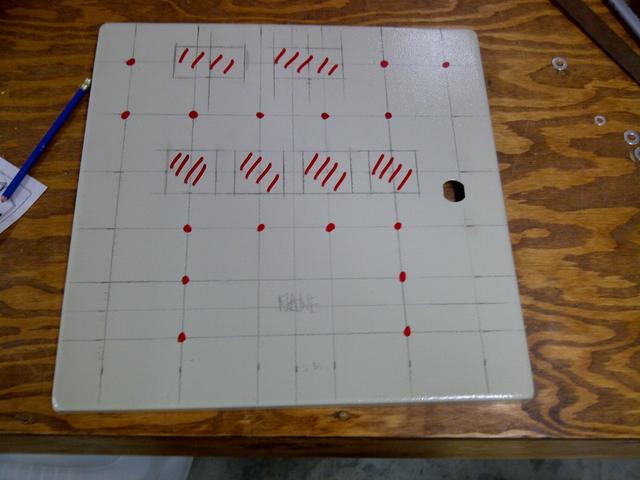

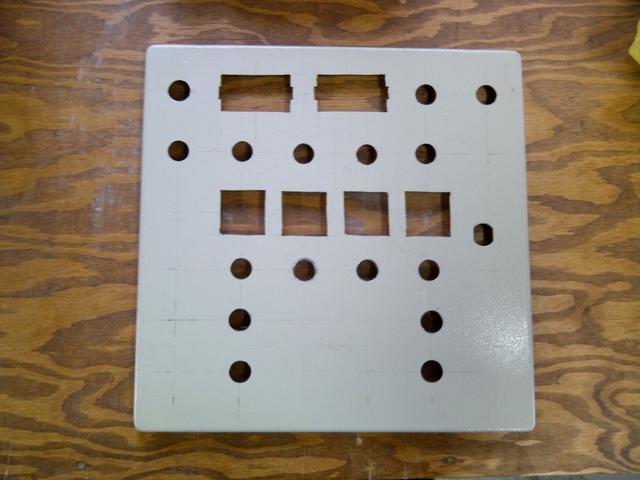

I am considering (ie, pretty damn sure) I'm going to tile the wall behind the brew stand for ease of cleaning and of course protection - OSB doesn't like wet. I'll be building a wooden vent hood lined with some sort of waterproof paneling (likely the next project as it's quick and easy to do while I wait for parts to arrive).

I have ordered nearly all the parts for the control panel and I'm working on sourcing and pricing all my keg fittings. I can't WAIT to get this thing together!

I've finally gotten to a point in my build that I have some pictures of stuff that I want to share. When we bought this house about 2 years ago, I knew that it was PERFECT for a larger, purpose-built brewery. I discovered TheElectricBrewery.com some time last year and have been salivating over it ever since.

Right now, I brew using some pretty basic equipment - a turkey fryer burner, big-ass aluminum pot and a cooler mash tun with stainless braid. I'm lucky enough to have gotten a free 100lb propane tank, and my equipment fits nicely in my well house, which, obviously, has a readily available source of water (its foundation is a 2500gal concrete cistern). The room is also small enough and very well insulated (to prevent freezing) that it works well as a fermentation room since there is already a heater in there (needed in the winter but not the summer, of course).

This is the new home of brewery 2.0, tentatively called "North Wall Brewing," since it occupies the north wall of my garage.

When we bought the place, the garage was neither insulated nor heated, so temperature swings are pretty wild in all seasons, especially the late spring and early fall when it's chilly at night and warm in the day. First order of business was to insulate and put up some walls:

We had an electrician run the lines for the heat before we did this. Due to a very, very busy summer I didn't have as much time as I'd liked to work on it, but finally managed to get the last of the OSB up a few days ago. This is the area NWB will occupy:

SWMBO wanted a ping pong table. She's better than I.

When I first thought about building the brewery, I assumed I'd be able to use this existing 220V outlet, but as you can see, it is a welding-type one that is only good for that purpose, something I learned from reading this and other forums and sites, thanks! Thankfully, I realized this before I put up the walls in the garage in that spot.

So I installed a new dryer outlet with the proper 30A 4-wire cabling, and ran it back to my panel where it now sits, waiting for a very expensive GFI breaker (at least $250) :-(

I got to work building the brew stand. First, I built a larger, modified version of it as my general-purpose work bench. A little higher, with a plywood top, and no bottom shelf, 8 feet long. Once that was done, I set to work on my stand. I'm really happy with the way it turned out.

Both stands, before sanding and staining:

I finished staining them last night, and I love the results. I used Minwax stain, Early American colour. We had cabinets with this stain at our last house. I love it.

I got that laundry sink for free - it's nearly brand-new. Since I'll really only be draining water and yeasties and non-toxic cleaning stuff, I'm going to run the drain for this either out the door into the grass, or through the wall and to a conveniently-located perimeter drain cleanout which drains the rainwater to a ditch below my property (probably the latter).

I got my hands on 3 used Sanke kegs, so I couldn't pass up the opportunity to convert them and save some major bucks on this build. I guess I can always upgrade later. I cut the tops off them and I'll be ordering fittings soon. I will also be shining them up like a boss.

In the left of the following photo, you can see my 1" water line that will be connected soon - then I will run 1/2" pex to the sink and create connections for the HLT and chiller. Just cold water, for now.

I am considering (ie, pretty damn sure) I'm going to tile the wall behind the brew stand for ease of cleaning and of course protection - OSB doesn't like wet. I'll be building a wooden vent hood lined with some sort of waterproof paneling (likely the next project as it's quick and easy to do while I wait for parts to arrive).

I have ordered nearly all the parts for the control panel and I'm working on sourcing and pricing all my keg fittings. I can't WAIT to get this thing together!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)