If you open it even a little bit than no, there's no chance it'll still be free of oxygen afterwards.Has anyone tried dry hopping into a keg that's purged with CO2 from fermentation? I have a batch fermenting, and I am thinking about dry hopping into the keg through the lid. I believe there's maybe four points left until FG (haven't done a FFT). Might do a spund as well. Will the keg still be free of oxygen?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

No oxygen dry hopping

- Thread starter SEndorf

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

VirginiaHops1

Well-Known Member

Has anyone tried dry hopping into a keg that's purged with CO2 from fermentation? I have a batch fermenting, and I am thinking about dry hopping into the keg through the lid. I believe there's maybe four points left until FG (haven't done a FFT). Might do a spund as well. Will the keg still be free of oxygen?

You'd have to load the keg with the hops at the beginning so you wouldn't need to open it after it's fully purged from fermentation. I struggle with limiting my O2 at dry hop as well but I don't have a conical and ferment in kegs. When I open the fermenter to dry hop I pump CO2 through the gas in while the top is open, hoping to create negative pressure while I dump the hops in. Then I'll seal and purge a bunch of times.

I think this works reasonably well but I still feel like it's inadequate because I know some oxygen is getting in there and mixing and purging won't fully remove it. I have purged serving kegs with jumpers and fermentation CO2 before, and what I did one time was hook up a dry hop keg already loaded with the hops to my fermenter. It was purged with fermentation gas, and I then jumped the beer straight into it to dry hop. I still transferred off to a purged serving keg afterwards to get off the hops. I only did this once but the batch turned out really well, and I plan to try it again on my next batch.

The downside to this method is obviously, the hops sitting at mid 60 degrees for 8-10 days during primary fermentation. But the upside it would seem is better O2 protection, so I need to figure out which method produces the best beer.

The downside to this method is obviously, the hops sitting at mid 60 degrees for 8-10 days during primary fermentation. But the upside it would seem is better O2 protection, so I need to figure out which method produces the best beer.

My LHBS stores hops on the shelf, in boxes. They aren't frozen or even refrigerated. So to me, hops sitting in a purged keg for 10 days is no different than sitting on a shelf at the LHBS.

I know there are some LHBS which keep hops in a freezer or refrigerator, and that is undoubtedly nice, but I have to wonder where those hops were before they arrived there, and how long they were sitting, in a box, in a warehouse, without temp control. I do keep all my hops at home in the freezer, but it's more about arresting whatever decline in quality might ensue by keeping them at room temp than anything else.

It even would be possible to put the keg in a ferm chamber and pass the CO2 through it in there. That would keep your hops cold if that's important to you.

VirginiaHops1

Well-Known Member

It even would be possible to put the keg in a ferm chamber and pass the CO2 through it in there. That would keep your hops cold if that's important to you.

Well, the dry hop keg is sitting in the ferm chamber, next to the fermenter so it can be hooked up with jumpers and purged. But obviously I don't ferment at refrigeration temps for my IPAs so that's the issue. Although like you I don't consider it a big issue, since my hops have most certainly been at room temp(or higher) quite a bit before they even get to me, so what's another 10 days. It's not like they're sitting on the counter, they are being purged by copious amounts of fermentation CO2. If I was receiving fresh, cold stored hops directly from a supplier I'd probably feel differently. I think this will probably become my SOP eventually, as I think the benefits outweigh the risks.

I think people are overreacting to the issue of hops sitting at room temp. The main factor in hop deterioration is oxydation and you cannot have that in an environment that is adequately purged of O2 no matter how high the temperature is.

Of course there are other factors in hop aging but since we're definitely not letting the hops sit for months before dropping them (end of primary for an ale is for me 3 to 4 days tops) I don't think they will come into play significanlty or even at all in such a short timeframe.

But if somebody really wants to be totally anal about that it would still be possible to rig a line from the chiller, wrap it around the dry-hopping gadget and have a small pump run glycol continuously (a really tiny pump is more than enough) through it so that hops will be kept cold or possibly even frozen until they are dropped in the FV.

Of course there are other factors in hop aging but since we're definitely not letting the hops sit for months before dropping them (end of primary for an ale is for me 3 to 4 days tops) I don't think they will come into play significanlty or even at all in such a short timeframe.

But if somebody really wants to be totally anal about that it would still be possible to rig a line from the chiller, wrap it around the dry-hopping gadget and have a small pump run glycol continuously (a really tiny pump is more than enough) through it so that hops will be kept cold or possibly even frozen until they are dropped in the FV.

I'm not too worried about the temperature the hops are sitting in. The keg in question is completely water and saniclean purged and is now empty. I don't see how adding dry hops to a keg that is being water purged would work? Or maybe I am misunderstanding.

The more I am thinking about I am going against the idea, as I believe oxygen saturated in the hops themselves could possibly negate the effect of dry hopping in the keg at the tail end of fermentation?

The more I am thinking about I am going against the idea, as I believe oxygen saturated in the hops themselves could possibly negate the effect of dry hopping in the keg at the tail end of fermentation?

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

I wouldn't do it. Back when I used to buy hops by the ounce at the LHBS, I bought a few ounces that smelled great. They were in those little resealable ziplock baggies, but they had been kept cold at the store. Well, I forgot to put them in the freezer when I got home. The next day, less than 24 hours later, they had zero hop aroma and smelled like dried grass. The went straight into the trash. That taught me to never leave hops out for any period of time at room temp. I would never buy hops that were sitting out on a shelf because you'll never know how long they were there. I'm amazed that any LHBS keeps hops out on a shelf. Wow. They need to invest in a freezer, or at least a fridge.

If you're into making hoppy beers the best they can be, keeping them frozen until you're ready to add them to your beer is the first thing you should be doing imo.

If you're into making hoppy beers the best they can be, keeping them frozen until you're ready to add them to your beer is the first thing you should be doing imo.

VirginiaHops1

Well-Known Member

I'm not too worried about the temperature the hops are sitting in. The keg in question is completely water and saniclean purged and is now empty. I don't see how adding dry hops to a keg that is being water purged would work? Or maybe I am misunderstanding.

It wouldn't work with a keg you're water purging. I purge mine sometimes with CO2 from fermentation(e.g. hook up a jumper from fermenter to 2nd keg, then blow-off from 2nd keg). You'd have to do this and load the 2nd keg with hops before you sealed it up.

VirginiaHops1

Well-Known Member

I wouldn't do it. Back when I used to buy hops by the ounce at the LHBS, I bought a few ounces that smelled great. They were in those little resealable ziplock baggies, but they had been kept cold at the store. Well, I forgot to put them in the freezer when I got home. The next day, less than 24 hours later, they had zero hop aroma and smelled like dried grass.

So the hops had been opened and exposed to O2(repeatedly?) at the LHBS, or they were in their original sealed/purged packaging? If opened there's a good chance they were majorly degraded before you even bought them. If it's a reputable supplier who packages/nitrogen purges their hops really well I don't think sitting at room temp is going to ruin them. You think that on the way to the LHBS hops are kept refrigerated the entire time? I order most of my supplies online so I know my hops are at room temp or a lot higher before I get them yet when I rip open the bags for the first time they always smell extremely fresh.

I have moved towards buying smaller quantities though, like 1 or 2 oz and only occasionally 8 oz if it's a good deal. 1 lb is too much for me because I can't vacuum seal and I noticed that aroma dropping off big time during long term storage even though I keep my hops in the freezer wrapped up pretty well after opening.

I wouldn't do it. Back when I used to buy hops by the ounce at the LHBS, I bought a few ounces that smelled great. They were in those little resealable ziplock baggies, but they had been kept cold at the store. Well, I forgot to put them in the freezer when I got home. The next day, less than 24 hours later, they had zero hop aroma and smelled like dried grass. The went straight into the trash. That taught me to never leave hops out for any period of time at room temp. I would never buy hops that were sitting out on a shelf because you'll never know how long they were there. I'm amazed that any LHBS keeps hops out on a shelf. Wow. They need to invest in a freezer, or at least a fridge.

If you're into making hoppy beers the best they can be, keeping them frozen until you're ready to add them to your beer is the first thing you should be doing imo.

But in that case, those hops had been opened. What about hops in sealed bags like this:

Those hops are sealed in an O2-free package (presumably), so even if not frozen, there's no oxidation going on. I'll bet you yours were oxidized.

I'm not too worried about the temperature the hops are sitting in. The keg in question is completely water and saniclean purged and is now empty. I don't see how adding dry hops to a keg that is being water purged would work? Or maybe I am misunderstanding.

The more I am thinking about I am going against the idea, as I believe oxygen saturated in the hops themselves could possibly negate the effect of dry hopping in the keg at the tail end of fermentation?

Similarly to how @VirginiaHops1 describes it--if you're just putting the hops in a keg that isn't purged, it's of no value. Even if it's purged, merely opening the lid will introduce at least some air, and thus some oxygen.

Most of us in this thread who are talking about putting them in a purged keg mean in a keg that is being repurged with fermentation gases.

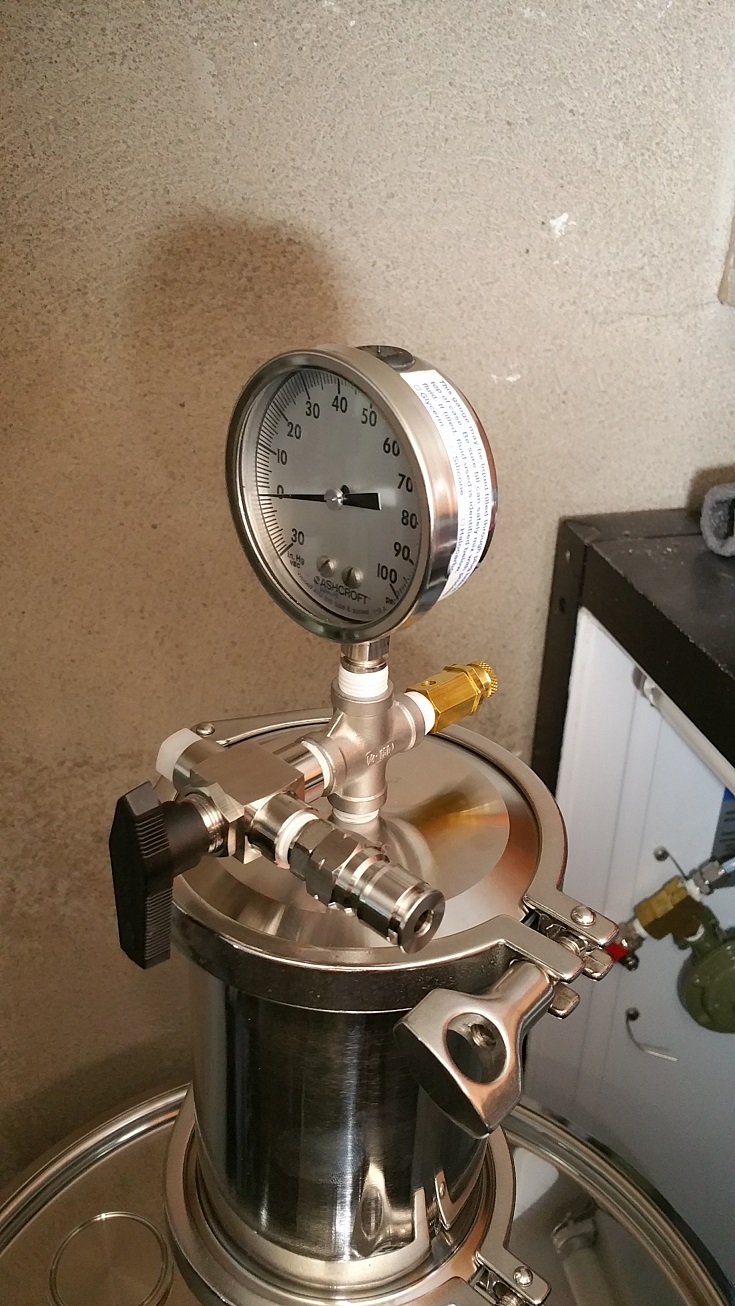

This pic here shows the process--it's my conical here, but I've done exactly the same thing using my bigmouth bubbler plastic fermenters. You just feed a line off the airlock/blowoff port to the OUT post of the keg, open the PRV (or install just a gas QD if pinlocks), and the fermentation gases go into the bottom of the keg and force out whatever is at the top.

So the idea would be to take a star-san purged keg that contains only bottled CO2, pop the top and drop in the hops, being careful to admit as little air as you can (unavoidable to admit at least a little). Then attach the OUT post to the blowoff, and let those fermentation gases purge that little bit of air out of the keg again.

In the pic below I have the gas coming off the pressure manifold on top (I use that instead of a blowoff cane), feeding into the keg. In this case I've daisy-chained a jumper for I use for transfers. I no longer do the daisy chain thing as I purge the jumper w/ beer, but if you just look at the line it terminates at the keg.

(BTW, this is even a way to purge a keg from the get-go without the hops. Clean the keg, sanitize it, dump the star-san, then close up. If you connect it like the pic, you'll fully purge the keg with ferm gases. Every 2 points of gravity produces about 1 volume of CO2. If you have, say, 50 points of gravity attenuation, that is 25 volumes of CO2. That's enough to purge that keg down to virtually unmeasurable O2, better than what bottled CO2 has.)

Thanks, I get it now. I guess I would had to do water purge with water, before purging with CO2 from fermentation. What I was getting at was opening a keg that 's being purged with CO2 from fermentation, and let the remaining extract in the fermenter purge the keg after the dryhop. But I guess a complete purge before the start of fermentation is a more surefire way to do it.

So the hops had been opened and exposed to O2(repeatedly?) at the LHBS

At least once

If opened there's a good chance they were majorly degraded before you even bought them.

They smelled great when I bought them. Less than 24 hours at room temp killed them. O2 probably played a part as well, but had they been frozen, they would not have degraded like they did at room temp.

You think that on the way to the LHBS hops are kept refrigerated the entire time?

Of course not, but you need to limit the amount of time they are kept at room temp or above.

Cool. Now the next step is to get rid of those silicone gaskets and replace them all witn NBR or VITON gaskets.

Silicone is porous an will let oxygen in like there's no tomorrow. Kind of invalidates the whole excercise.

Silicone is porous an will let oxygen in like there's no tomorrow. Kind of invalidates the whole excercise.

- Joined

- Aug 12, 2013

- Messages

- 2,066

- Reaction score

- 2,729

Beautiful setup

Cool. Now the next step is to get rid of those silicone gaskets and replace them all witn NBR or VITON gaskets.

Silicone is porous an will let oxygen in like there's no tomorrow. Kind of invalidates the whole excercise.

Is this a real concern? Does it eliminate the Spike Unitanks from LODO consideration due to that ginormous proprietary silicone gasket? (I know @mongoose33 is using one anyway.) Assume there is no way to get a Viton gasket to replace that guy. Also is Viton really ok for use in food & beverage applications?

Is this a real concern? Does it eliminate the Spike Unitanks from LODO consideration due to that ginormous proprietary silicone gasket? (I know @mongoose33 is using one anyway.) Assume there is no way to get a Viton gasket to replace that guy. Also is Viton really ok for use in food & beverage applications?

I'm trying to figure out how it is my beer tastes as good as it does even though I'm not using "Viton" gaskets.

Cavpilot2000

Well-Known Member

Most of us doing LOB dry hopping are indeed adding the dry hops to a purged keg just before spunding. There are a few tricks that will help:

1: before opening the purged keg, attach CO2 to the beer out post and put a slow flow of gas into the keg (like 1PSI). You should still be able to open the keg by opening the relief valve.

2: open the keg and increase the flow of CO2 (which is being pumped into the bottom of the keg and now flowing out the open hole)

3: add the hops quickly but with as little disturbance and introduction of air as possible

4: CLose the keg, keep the gas flowing in and open the relief valve several times.

5: Transfer your ready-to-spund beer into the keg immediately.

You will absolutely still be introducing O2 into the keg this way, but these steps will minimize it, and the active fermentation required to spund should consume most, if not all, of what you introduced.

It's not perfect LOB, but that's about what most of us do and it doesn't require and special equipment.

1: before opening the purged keg, attach CO2 to the beer out post and put a slow flow of gas into the keg (like 1PSI). You should still be able to open the keg by opening the relief valve.

2: open the keg and increase the flow of CO2 (which is being pumped into the bottom of the keg and now flowing out the open hole)

3: add the hops quickly but with as little disturbance and introduction of air as possible

4: CLose the keg, keep the gas flowing in and open the relief valve several times.

5: Transfer your ready-to-spund beer into the keg immediately.

You will absolutely still be introducing O2 into the keg this way, but these steps will minimize it, and the active fermentation required to spund should consume most, if not all, of what you introduced.

It's not perfect LOB, but that's about what most of us do and it doesn't require and special equipment.

Is this a real concern? Does it eliminate the Spike Unitanks from LODO consideration due to that ginormous proprietary silicone gasket? (I know @mongoose33 is using one anyway.) Assume there is no way to get a Viton gasket to replace that guy. Also is Viton really ok for use in food & beverage applications?

Lol, no, it's not a concern with a dry hopping chamber considering the what, one minute that the hops are in there for? I'm on day 5 or 6 of a vacuum test. Those silicone screen doors are still holding vacuum.

That is one cool set up!

BTW what conical is that?

Thanks! It's a 15 gallon Stout.

I find it very significant that you LODO "converts" get your panties all in a bunch over stuff like CO2 purity and oxygen ingress through bottle caps but don't have the foggiest idea about the characteristics of the materials that you employ in your fermenters.I'm trying to figure out how it is my beer tastes as good as it does even though I'm not using "Viton" gaskets.

Newsflash: you get a shitload more O2 ingress from your silicone gasket than you would get from a tiny bottle cap. And if you're doing closed transfers using silicone hoses you'd be surprised at how little your system is actually "closed" to O2 ingress.

Here's some hard data for the stubborn "unbelievers". It's the first source I could find and unfortunately it doesn't list values for O2 but if you look at the CO2 column it will still give you an idea of how the different materials compare to each other.

EPDM: 85

Viton: 5

Silicone: 2,000

That's right boys and gals, silicone is approximately 400 times more permeable than Viton. As a matter of fact it's so permeable that it's used as exchange surface in cardiopulmonary bypass systems (the ones used for open heart surgery).

And if you're doing closed transfers using silicone hoses you'd be surprised at how little your system is actually "closed" to O2 ingress.

Here's some hard data for the stubborn "unbelievers". It's the first source I could find and unfortunately it doesn't list values for O2 but if you look at the CO2 column it will still give you an idea of how the different materials compare to each other.

EPDM: 85

Viton: 5

Silicone: 2,000

HAHAHA, I knew you probably looked at a permeability coefficient table and then made your comment about the silicone gaskets above. Hilarious. That is not hard data. Hard data would be DO measurements of actual beer that had flowed through various materials or beer that was fermented in a fermenter with various gasket materials.

As I stated earlier, in a no O2 dry hop chamber, which holds hops for a minute, it's laughable that the material matters. How much do you think is getting in? I has been holding vacuum for DAYS.

That's right boys and gals, silicone is approximately 400 times more permeable than Viton.

Why are you so hung up on Viton? Tri-clamp gaskets are made from much more O2 impermeable materials. I guess maybe because it's the first source you could find...

Cavpilot2000

Well-Known Member

Well that sounds great except you totally ignore the time factor. The time beer spends in a silicone tube during transfer does allow a small but relatively insignificant amount to O2 in.I find it very significant that you LODO "converts" get your panties all in a bunch over stuff like CO2 purity and oxygen ingress through bottle caps but don't have the foggiest idea about the characteristics of the materials that you employ in your fermenters.

Newsflash: you get a poopyload more O2 ingress from your silicone gasket than you would get from a tiny bottle cap. And if you're doing closed transfers using silicone hoses you'd be surprised at how little your system is actually "closed" to O2 ingress.

Here's some hard data for the stubborn "unbelievers". It's the first source I could find and unfortunately it doesn't list values for O2 but if you look at the CO2 column it will still give you an idea of how the different materials compare to each other.

EPDM: 85

Viton: 5

Silicone: 2,000

That's right boys and gals, silicone is approximately 400 times more permeable than Viton. As a matter of fact it's so permeable that it's used as exchange surface in cardiopulmonary bypass systems (the ones used for open heart surgery).

AND, if the beer were sitting it the tubes for a long time, that might make a difference, but most of us upgrade our tap lines where the beer actually spends some time to less permeable materials.

Also, that’s why we recommend spunding, so the active fermentation consumes the tiny amount of O2 that is introduced during transfers.

Add to that the fact that oxygen permeable materials are irrelevant during active fermentation (you can successfully LOB with open fermentation).

If you’re going to take the trouble to comment on a thread about LOB, at least learn a little more about the subject you are choosing to denigrate.

And at the end of the day none of us “LODO converts” believes that we can totally eliminate oxidation over time. It’s simply not possible. We just try to prevent pre-oxidizing our wort and extend shelf life.

But go ahead and keep believing that HSA is a myth and oxygen doesn’t hurt your beer. We with our panties in a bunch (i.e. those trying to reduce the effect of oxidation on our beer) don’t mind at all.

Lastly, you really are showing a great character trait here: taking time to comment on a LOB (LODO) thread just to try to put others down and act like you know more, when you obviously think LOB is a waste of time. If you think LOB is bunk, you could just stay away from the LOB threads, but no, you chose to go out of your way to try and piss on somebody else's parade. Make sure you pass that trait on to your kids - everyone loves a person who takes time out of their day to boost their sense of self by putting others down. They’ll be very popular.

Cheers!

Last edited:

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

I find it very significant that you LODO "converts" get your panties all in a bunch over stuff like CO2 purity and oxygen ingress through bottle caps but don't have the foggiest idea about the characteristics of the materials that you employ in your fermenters.

What gives you the impression we don't understand the properties of the materials we use? For your edification it is a topic of regular discussion at the LowOx forum. Where possible we sub Buna-N and teflon. When that is not workable for things like silicone hose and seals we wrap with a teflon barrier layer over that. So don't get your speedos in a bunch trying to know it all on a subject you clearly do not.

hopjuice_71

Well-Known Member

- Joined

- Mar 26, 2016

- Messages

- 373

- Reaction score

- 374

Whoa, this is the kind of stuff that gets a thread shut down. I think most people understand the issues that the materials we use have with respect to gas permeability. What I have a hard time understanding is the concept of how silicone, if it is so gas permeable, still works to hold pressure when it is used in gaskets and o-rings in unitanks and kegs, respectively. And, if there is a situation of significant outward CO2 escape through the silicone under pressure, how the mass transfer capacity of the silicone could possibly support ingress of O2 (yes, it understand the concept of concentration gradients but material, whatever it is, can only support so much "stuff" moving through it). Seems a bit like pouring a beer in a river and assuming it will flow upriver. Maybe I have this wrong though.

Excuse me? Are you saying that silicone gaskets are not made of actual silicone rubber? Viton is simply one of the less permeable materials and it's what all the gaskets in my fermenter are made of, incidentally. EPDM is slightly more permeable but still hundreds of times better than silicone.Why are you so hung up on Viton? Tri-clamp gaskets are made from much more O2 impermeable materials. I guess maybe because it's the first source you could find...

FYI silicone gaskets only make sense in those applications where they have to withstand extremely low temperatures, such as cryogenics. EPDM and FKM are only marginally more expensive than silicone and perfectly suited to the temperature ranges you'll encouter in brewing equipment, botwh warm and cold side and that is what gaskets in real breweries are always made of, BTW. It really beats me why manufacturers of homebrew equipment would pick the worst possible material for the gaskets just to shave off a few pennies.

It's called diffusion and yes it works "upriver" as well. Seems counterintuitive but that's how it works, pressure will not protect you from it in any way. That is why oxygen ingress in pressurized bottles is a real issue, as I'm sure you're aware. As for holding pressure, when dealing with oxygen ingress we're dealing with values in the ppb range. The amounts are so small relative to the volume that to detect changes in pressure in either direction would require an incredibly accurate manometer. Incidentally, I've never seen a keg with gaskets made of silicone.Whoa, this is the kind of stuff that gets a thread shut down. I think most people understand the issues that the materials we use have with respect to gas permeability. What I have a hard time understanding is the concept of how silicone, if it is so gas permeable, still works to hold pressure when it is used in gaskets and o-rings in unitanks and kegs, respectively. And, if there is a situation of significant outward CO2 escape through the silicone under pressure, how the mass transfer capacity of the silicone could possibly support ingress of O2 (yes, it understand the concept of concentration gradients but material, whatever it is, can only support so much "stuff" moving through it). Seems a bit like pouring a beer in a river and assuming it will flow upriver. Maybe I have this wrong though.

Believe me, I kow for a fact that HSA is not a myth. What is a myth is what you make it out to be and also the idea that your totally unproven methods are in the least bit effective at actually improving beer quality.But go ahead and keep believing that HSA is a myth and oxygen doesn’t hurt your beer. We with our panties in a bunch (i.e. those trying to reduce the effect of oxidation on our beer) don’t mind at all.

Similar threads

- Replies

- 2

- Views

- 550

- Replies

- 34

- Views

- 2K

- Replies

- 9

- Views

- 1K

- Replies

- 102

- Views

- 8K

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)