Having just gotten my shipment in, and discovering that Bobby is a 20-mile-stone's-throw from home, I have a quick review.

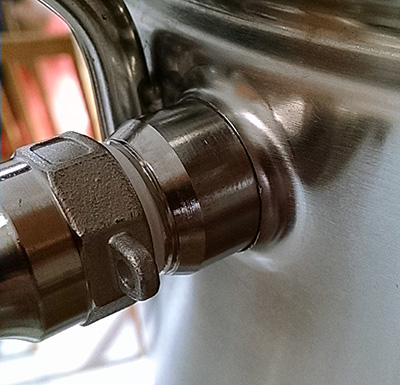

These things are incredible. It took longer to tear down the kettle and clean it afterwards than it did to solder these in. Get the install tool. It's worth every penny! It made the install very, very easy.

I soldered these with a mapp gas torch, from the outside and focusing most of the heat on the fitting.

Tested with water, the whirlpool action was perfect. This will be great for chilling and whirlpooling the trub to the center of the kettle.

Bobby, thanks for the great hardware and the great service!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)