You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New eBIAB build, questions about controls

- Thread starter The_Bishop

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

Both of those diagrams are awesome.

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

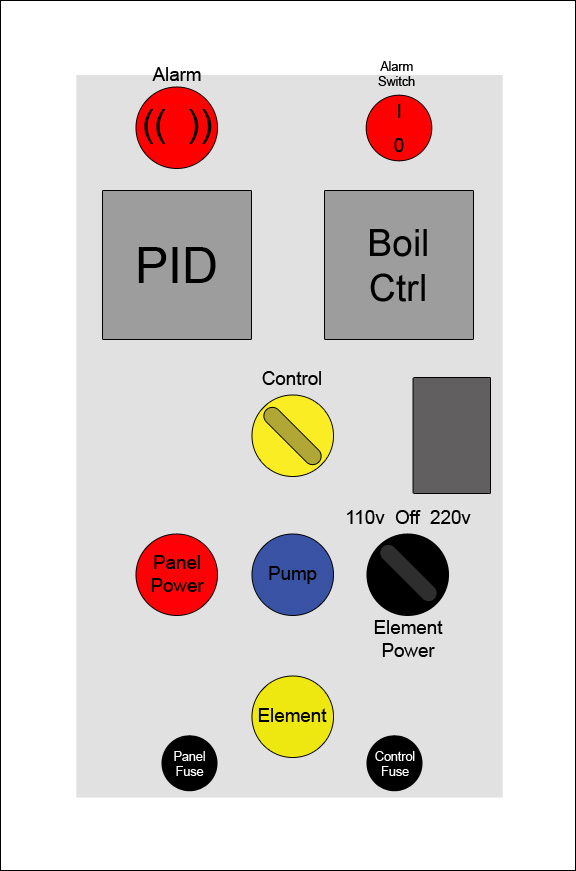

So I've been working on my brew panel layout.

Pretty sure I'm happy with this one, only changed it a dozen times or so. :cross:

The light gray area shown is the 'workable' area of the door, avoids the seal and lip of the enclosure.

The yellow 'element' is an indicator that's wired into the element so I can see when it's firing.

'Power', 'Pump' and 'Heat' are lighted push button switches.

Everything is to scale.

Any feedback?

Pretty sure I'm happy with this one, only changed it a dozen times or so. :cross:

The light gray area shown is the 'workable' area of the door, avoids the seal and lip of the enclosure.

The yellow 'element' is an indicator that's wired into the element so I can see when it's firing.

'Power', 'Pump' and 'Heat' are lighted push button switches.

Everything is to scale.

Any feedback?

Last edited:

So I've been working on my brew panel layout.

Pretty sure I'm happy with this one, only changed it a dozen times or so. :cross:

The light gray area shown is the 'workable' area of the door, avoids the seal and lip of the enclosure.

The yellow 'element' is an indicator that's wired into the element so I can see when it's firing.

'Power', 'Pump' and 'Heat' are lighted push button switches.

Everything is to scale.

Any feedback?

Aren't you missing a switch? How are you selecting whether the PID or Power Controller will drive the SSR?

Brew on

Maybe he's running them in line as I suggested.

Maybe he's running them in line as I suggested.

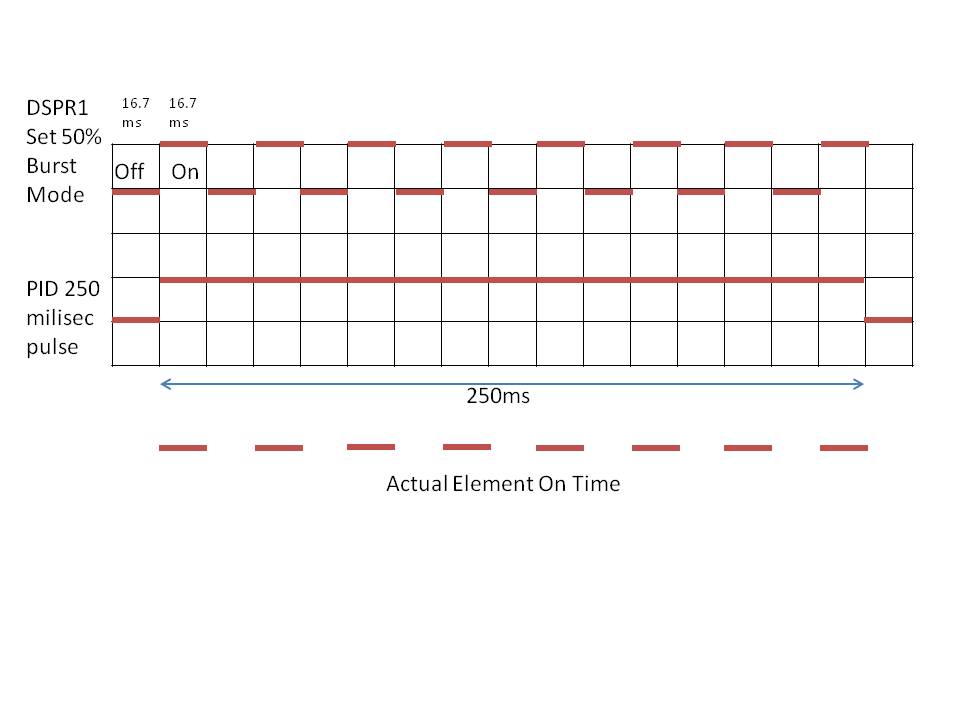

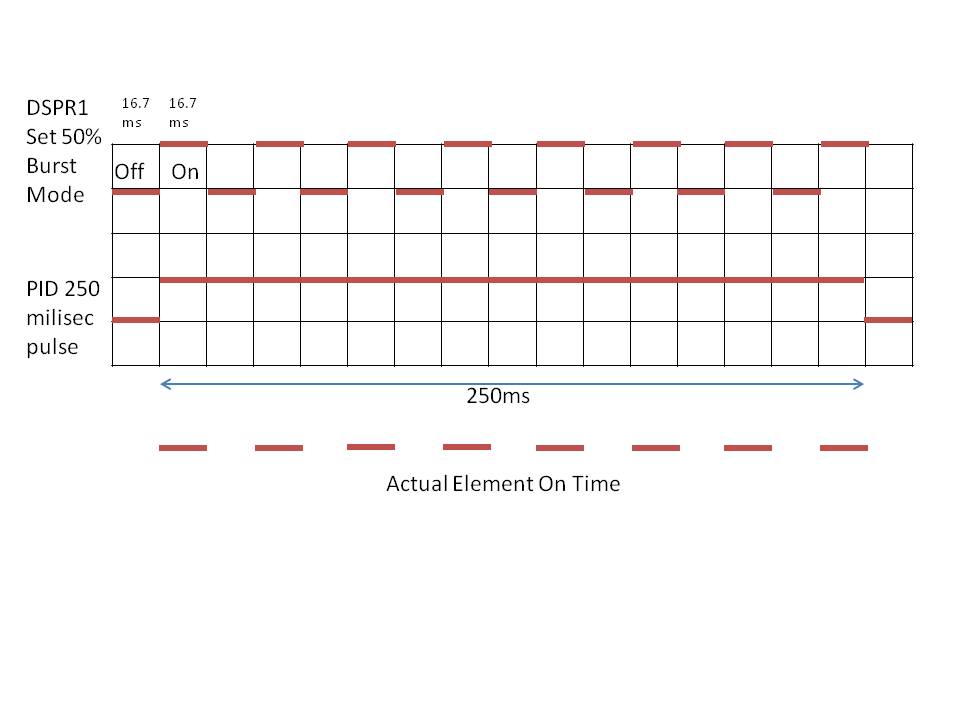

The drawing doesn't look like an SSR in series with SSVR is being used. An SSR driven by a PID in series with an SSR driven by a DSPR1 wouldn't work very well as you would need to sync them up somehow, since the DSPR1 doesn't operate in phase angle mode.

Brew on

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

My current plan was to run it as Bobby suggested, PID running one SSR gated through another SSR controlled by the DSPR1.

Assume I'm an idiot (I'm not, entirely) and explain what's wrong with that setup, please? I was under the impression that the PID would trigger the first SSR to power up the element, and the second SSR/DSPR would regulate the percentage of the power to get through via pulsing SSR.

If I'm wrong, it's easy enough to fix as it's just a drawing at this point.

Assume I'm an idiot (I'm not, entirely) and explain what's wrong with that setup, please? I was under the impression that the PID would trigger the first SSR to power up the element, and the second SSR/DSPR would regulate the percentage of the power to get through via pulsing SSR.

If I'm wrong, it's easy enough to fix as it's just a drawing at this point.

My current plan was to run it as Bobby suggested, PID running one SSR gated through another SSR controlled by the DSPR1.

Assume I'm an idiot (I'm not, entirely) and explain what's wrong with that setup, please? I was under the impression that the PID would trigger the first SSR to power up the element, and the second SSR/DSPR would regulate the percentage of the power to get through via pulsing SSR.

If I'm wrong, it's easy enough to fix as it's just a drawing at this point.

I'm not sure how to explain it easily. If you read the appendix in the DSPR1 manual it may help understand why putting these in series may cause problems.

Brew on

The concern is that the SSR turns on when the AC wave crosses 0v. So if your PID is generating very short pulses, the SSR controlled by the boil control may not see enough AC cycles to turn on as much as the controller thinks it is.

The boil controller is taking the mains frequency via its power supply to synchronise its firing of the SSR.

You may have more success using one of the alternative modes that the DSPR offers over the stock burst mode. Equally you could put the PID into manual mode and set it to 100%, or set the SV to something like 250f which should have it firing 100% output anyway.

IIRC the last suggestion was Bobbys, as if the PID SSR is being held on then the boil control SSR will get the full AC waveform so no worries.

The edge case is if you were trying to use the PID to hold an established temperature and also dial down the element power with the DSPR. In which case you may see substantially less output than you'd predict due to the phasing issue

The boil controller is taking the mains frequency via its power supply to synchronise its firing of the SSR.

You may have more success using one of the alternative modes that the DSPR offers over the stock burst mode. Equally you could put the PID into manual mode and set it to 100%, or set the SV to something like 250f which should have it firing 100% output anyway.

IIRC the last suggestion was Bobbys, as if the PID SSR is being held on then the boil control SSR will get the full AC waveform so no worries.

The edge case is if you were trying to use the PID to hold an established temperature and also dial down the element power with the DSPR. In which case you may see substantially less output than you'd predict due to the phasing issue

The concern is that the SSR turns on when the AC wave crosses 0v. So if your PID is generating very short pulses, the SSR controlled by the boil control may not see enough AC cycles to turn on as much as the controller thinks it is.

The boil controller is taking the mains frequency via its power supply to synchronise its firing of the SSR.

You may have more success using one of the alternative modes that the DSPR offers over the stock burst mode. Equally you could put the PID into manual mode and set it to 100%, or set the SV to something like 250f which should have it firing 100% output anyway.

IIRC the last suggestion was Bobbys, as if the PID SSR is being held on then the boil control SSR will get the full AC waveform so no worries.

The edge case is if you were trying to use the PID to hold an established temperature and also dial down the element power with the DSPR. In which case you may see substantially less output than you'd predict due to the phasing issue

^^^ Yes.

I think it is cleaner to switch the control inputs to the SSR between the PID and DSPR1. Then there is no ambiguity about just what the waveform to the element looks like. Also, the SSR's have a max forward voltage drop specified as 1.5V meaning if you have 240V power, the element may only see 238.5V. With two SSR's in series, the element may see only 237V. So, max element power is slightly reduced. Maybe more of an issue is you now have two SSR's dissipating heat instead of one, so you need more cooling for the SSR's. Nothing insurmountable, just more little things that make the series SSR solution less than optimal IMO.

Brew on

BeardedBrews

Well-Known Member

Switchable 120/240 is something I really wish I had in my eBIAB, but I'm not sure I see the value in the vssr. I understand the desire to have power control, but in my experience, you just don't need that level of tuning.

I recirculate my mash in my cold garage with the 240v element at 3-5% on the manual pid, it holds perfectly. (+\- .5) At boil I jump it up to 100% until hot break, and then back down to 55 for the boil.

If I had the 120 option I could get more consistent heat during the mash by having more on time without overheating, plus it would reduce or eliminate the scorch risk, even with a heavy mash on the element. It would probably also mean I could let the pid maintain mash instead of manual. I'm just not seeing where I would want to have some power level between 5500 and 1375.

I recirculate my mash in my cold garage with the 240v element at 3-5% on the manual pid, it holds perfectly. (+\- .5) At boil I jump it up to 100% until hot break, and then back down to 55 for the boil.

If I had the 120 option I could get more consistent heat during the mash by having more on time without overheating, plus it would reduce or eliminate the scorch risk, even with a heavy mash on the element. It would probably also mean I could let the pid maintain mash instead of manual. I'm just not seeing where I would want to have some power level between 5500 and 1375.

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

OK, now I have my head wrapped around it. I was originally thinking of an SSR in the terms of a very fast mechanical relay, and the dspr1 being independent of the source power being switched, but that's not the case.

Not a huge deal, as thankfully I have the switch and the drawing is easy to change.

The whole idea about controlling the element power is to prevent any sort of scorching while doing a temperature controlled recirculating mash. Is it really an issue that needs to be worried about? The element is a 5500 Watt ripple element, 60 watts per inch ULWD.

Bearded, how come you don't use the PID mode when mashing? Have you had a scorching issue? I would tend to think that the PID would use the same power to the element to maintain temps as you are currently.

Doug, in your diagram for the switchable control between the PID and the DSPR1, you show a 3 position switch with 4 NO contacts. Any reason it can't be a two position switch? I was thinking about using the SW16 with two sets of NO/NC contacts, and using the light in the switch as an element power on indicator.

Not a huge deal, as thankfully I have the switch and the drawing is easy to change.

The whole idea about controlling the element power is to prevent any sort of scorching while doing a temperature controlled recirculating mash. Is it really an issue that needs to be worried about? The element is a 5500 Watt ripple element, 60 watts per inch ULWD.

Bearded, how come you don't use the PID mode when mashing? Have you had a scorching issue? I would tend to think that the PID would use the same power to the element to maintain temps as you are currently.

Doug, in your diagram for the switchable control between the PID and the DSPR1, you show a 3 position switch with 4 NO contacts. Any reason it can't be a two position switch? I was thinking about using the SW16 with two sets of NO/NC contacts, and using the light in the switch as an element power on indicator.

jeffmeh

Well-Known Member

- Joined

- Feb 26, 2009

- Messages

- 2,145

- Reaction score

- 216

OK, now I have my head wrapped around it. I was originally thinking of an SSR in the terms of a very fast mechanical relay, and the dspr1 being independent of the source power being switched, but that's not the case.

Not a huge deal, as thankfully I have the switch and the drawing is easy to change.

The whole idea about controlling the element power is to prevent any sort of scorching while doing a temperature controlled recirculating mash. Is it really an issue that needs to be worried about? The element is a 5500 Watt ripple element, 60 watts per inch ULWD.

Bearded, how come you don't use the PID mode when mashing? Have you had a scorching issue? I would tend to think that the PID would use the same power to the element to maintain temps as you are currently.

Doug, in your diagram for the switchable control between the PID and the DSPR1, you show a 3 position switch with 4 NO contacts. Any reason it can't be a two position switch? I was thinking about using the SW16 with two sets of NO/NC contacts, and using the light in the switch as an element power on indicator.

Probably best to switch through open, hence the 3 position switch. And for your element on light, you want a 240v light wired in parallel with the element. Have fun.

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

Jeff,

I have an element firing light, and it is a 240v light that will be in parallel with the element.

I was thinking more in line with using the light on the PID/DSPR1 control selector switch to indicate that the contactor is indeed switched on and has power flowing through it. In the diagram, it would be the 'Element power on' light.

The switch will only be carrying the SSR control signal, no high power. I would think a DPDT switch would be fine; that's all they show in the DSPR1 manual using this configuration.

I have an element firing light, and it is a 240v light that will be in parallel with the element.

I was thinking more in line with using the light on the PID/DSPR1 control selector switch to indicate that the contactor is indeed switched on and has power flowing through it. In the diagram, it would be the 'Element power on' light.

The switch will only be carrying the SSR control signal, no high power. I would think a DPDT switch would be fine; that's all they show in the DSPR1 manual using this configuration.

BeardedBrews

Well-Known Member

Bearded, how come you don't use the PID mode when mashing? Have you had a scorching issue? I would tend to think that the PID would use the same power to the element to maintain temps as you are currently.

In theory the PID would be the best way to maintain the mash for sure. In practice it takes some time / effort to properly tune the PID, even with the auto-tuning models. The best tuning would be done during a mash, but I haven't had the time/grain to go through that exercise.

My current tuning for strike water likes to over-shoot by 3-5° and then settle back down very slowly. Adding grain to the equation slows the response down even more, so there is more overshoot. Rather than mess with it, I've just been using manual mode. I am certain that if I went in and manually tweaked the P/I/D settings, and then possibly let it re-run an auto tune, that it would settle in comfortably for me.

The only time I've seen signs of scorching on my 5500w straight fold-back element was when I played around with a 30% manual to do a mash-out. I do not detect any hint of toast or burn in the finished beer, and there was no damage or staining on my bag, but a 1-2" section of the normal beige sludge on the element had blackened by the time I drained the kettle and started cleanup. Your ripple element should be significantly less likely to scorch.

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

Where do you have your temp sensor, out of curiosity? I'm fairly sure I'm sticking it in the kettle outlet, as the only time I'll be concerned about temps is when I'm recirculating. My theory is if I keep the wort that was just circulating past the element at the correct temps, I won't prematurely denature the enzymes. And if everything else works right, I'll be circulating quick enough that temperature stratification shouldn't be an issue.

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

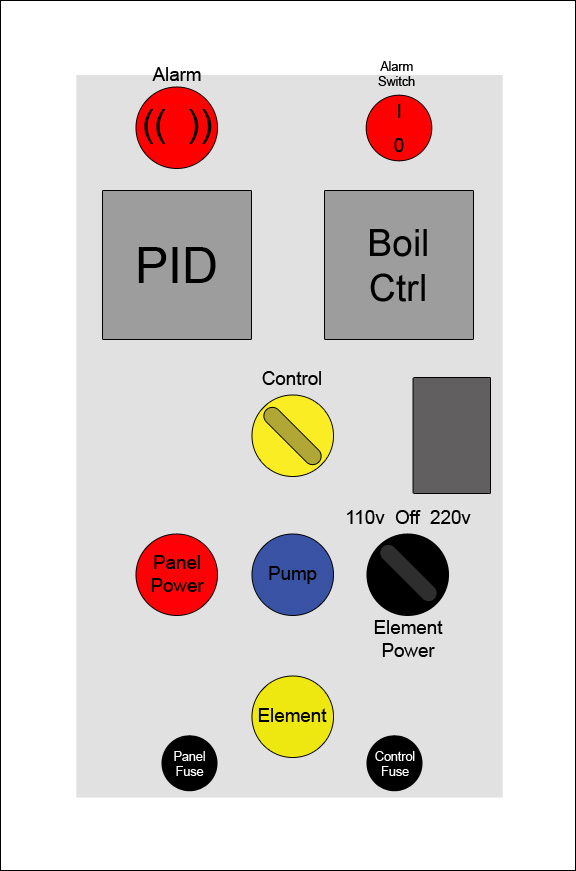

In light of the recent discussion about using two SSRs in series being an issue, here's the new theoretical panel with the capability of powering the element with either 110v or 220v, based on Doug's schematic in post #31 of this thread.

Only needed to order the SW16 and the additional set of contacts for it. Hopefully, I'll be at the actually assembling things stage soon, instead of the 'make plans and keep second-guessing' stage I'm currently at.

On a related note: The SSR will have one hell of a huge heat sink, I ordered a scratch and dent enclosure with a dual SSR heat sink that mounts on top. With only one SSR, heat dissipation shouldn't be an issue. Also, I'll now have an extra SSR.

Only needed to order the SW16 and the additional set of contacts for it. Hopefully, I'll be at the actually assembling things stage soon, instead of the 'make plans and keep second-guessing' stage I'm currently at.

On a related note: The SSR will have one hell of a huge heat sink, I ordered a scratch and dent enclosure with a dual SSR heat sink that mounts on top. With only one SSR, heat dissipation shouldn't be an issue. Also, I'll now have an extra SSR.

Last edited:

BeardedBrews

Well-Known Member

Where do you have your temp sensor, out of curiosity?

I went cheap on my kettle, so my stubby PT-100 is just wing-nutted through the kettle wall, low in the kettle, across from the pick-up tube. This is not ideal from a control standpoint, but what I have found is that if I keep my circulation rate high, there is very little difference between what is read on that probe and what I measure when I stick a thermometer into the return wort stream.

I still think I want to move the location of the sensor to somewhere in the plumbing, but on some level it shouldn't matter. If the pumping rate is high, and the insulation on the vessel is good, then the temperature everywhere should be the same.

...

Doug, in your diagram for the switchable control between the PID and the DSPR1, you show a 3 position switch with 4 NO contacts. Any reason it can't be a two position switch? I was thinking about using the SW16 with two sets of NO/NC contacts, and using the light in the switch as an element power on indicator.

The two position switch should work, as long as the switch operates in the "break before make" mode for the NO/NC pairs. Most switches are designed to work this way.

I wouldn't use the same scheme to switch between 120V/240V as the center off position is needed to positively kill power to the element, and the time required to switch thru the off position gives the on contactor time to drop before the off contactor picks (break before make.)

I like the idea of using the LED in the SW16 to indicate power is enabled to the elements.

Brew on

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

The 120/240 switch is a 3 position center off switch, for the exact reasons you mention.

Looks like I have a final design, now to nut up and start cutting. *gulp*

Looks like I have a final design, now to nut up and start cutting. *gulp*

Some of you guys are a lot smarter than I am. I got a C in my first industrial controls class and was 16 credits short of a EE so help me better understand the problem with inline SSRs please.

I get the extra heat dissipation argument just fine. It just seems odd to select between full power and quarter power via voltage switch when the DSPR1 is an infinite voltage selector (in practice).

Does this not work as I think it does?

I get the extra heat dissipation argument just fine. It just seems odd to select between full power and quarter power via voltage switch when the DSPR1 is an infinite voltage selector (in practice).

Does this not work as I think it does?

BeardedBrews

Well-Known Member

Too late for a panel layout suggestion?

This option adds one more indicator light, but the symmetry seemed nice.

This option adds one more indicator light, but the symmetry seemed nice.

Too late for a panel layout suggestion?

This option adds one more indicator light, but the symmetry seemed nice.

Separate lights for 120V and 240V operation would require that the lights be put in parallel with the contactor coils rather across the contactor outputs. Personally, I would rather have the light follow the actual contactor output than the contactor input (direct indication rather than indirect indication.) Having the light on the output also lets you make sure that the contactor that was on has dropped when switching between voltages (light will go out), to help you from switching too fast.

Brew on

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

Bobby:

Heat dissipation isn't an issue; I've got heatsink to spare, as I ordered a dual SSR heatsink (rated for 60 amps worth of SSR).

I didn't mean for this to turn into a pissing match, I just want to make sure I do this the right way the first time.

I popped the SSR in series question to Auber's tech support E-mail, I guess I'll see what comes back from them.

And... It looks like I'm back to the 'make plans and keep second-guessing' stage.

Heat dissipation isn't an issue; I've got heatsink to spare, as I ordered a dual SSR heatsink (rated for 60 amps worth of SSR).

I didn't mean for this to turn into a pissing match, I just want to make sure I do this the right way the first time.

I popped the SSR in series question to Auber's tech support E-mail, I guess I'll see what comes back from them.

And... It looks like I'm back to the 'make plans and keep second-guessing' stage.

No, please don't take it as a pissing match. I'm not puffing my chest. I'm honestly asking since I want to understand it if I'm mistaken.

I think that in practice it may work just fine. Particularly as you would likely be using either the PID or the boil control, and set whichever you aren't using to 100% output.

The problem may come if you have a very low duty cycle from one or the other SSR controller. They are both syncing their ON pulses to the mains frequency, but the SSRs are going to lag behind the control input.

So if the first SSR is delayed by 1/2 a cycle, the second SSR will not turn on until the next zero crossing. At least if my memory serves correctly, the SSR needs to see the voltage coming down to zero in order to turn on, it won't just turn on with no voltage across the load terminals.

So if your first PID is running a 50% duty cycle, and the second boil control is also running a low duty cycle then you may have issues with the actual SSR being in coordination. The boil control and PID will be in sync as they both reference mains frequency but it doesn't necessarily follow that the SSRs will sync up

This is theoretical though, in actual use scenarios you may never see this happen.

The problem may come if you have a very low duty cycle from one or the other SSR controller. They are both syncing their ON pulses to the mains frequency, but the SSRs are going to lag behind the control input.

So if the first SSR is delayed by 1/2 a cycle, the second SSR will not turn on until the next zero crossing. At least if my memory serves correctly, the SSR needs to see the voltage coming down to zero in order to turn on, it won't just turn on with no voltage across the load terminals.

So if your first PID is running a 50% duty cycle, and the second boil control is also running a low duty cycle then you may have issues with the actual SSR being in coordination. The boil control and PID will be in sync as they both reference mains frequency but it doesn't necessarily follow that the SSRs will sync up

This is theoretical though, in actual use scenarios you may never see this happen.

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

Ok, here's a hypothetical question in regards to the timing of the SSRs:

They're both getting the signals from the power being switched, right? So when the first SSR lights up, they're more or less both in sync nearly instantaneously, as they're both seeing the same sine wave from the power. I'm also wondering if the 'leakage' past the SSR would be enough to serve the purpose of a 'carrier wave' of sorts.

Of course, I don't know jack-all about any of this aside from knowing my way around a schematic and a solid knowledge of how to wire up components. I'm shooting in the dark, so to speak.

They're both getting the signals from the power being switched, right? So when the first SSR lights up, they're more or less both in sync nearly instantaneously, as they're both seeing the same sine wave from the power. I'm also wondering if the 'leakage' past the SSR would be enough to serve the purpose of a 'carrier wave' of sorts.

Of course, I don't know jack-all about any of this aside from knowing my way around a schematic and a solid knowledge of how to wire up components. I'm shooting in the dark, so to speak.

Not quite. The SSR switches on at a zero crossing. It takes time to know that it has to switch on, so if the input is fired at one zero crossing, you have to wait 120th/sec before it can switch on. So you are likely losing half a cycle on the first SSR. Then the second SSR has to go through the same thing after the first SSR has turned on.

I don't know that you'll get enough leakage current through the first SSR, and IIRC an SSR needs a certain amount of voltage across the load terminals to work correctly.

The PID and boil control don't actually know if the SSRs have successfully turned on, they can only regulate their own output and assume that it is 100% effective.

Like I said though this should really be academic in practice, you will be using either the PID for mash control when you would set the boil control to 100%, or have the PID set to say 250F or 100% manual power and use the boil control for boiling. So in actual use there should be no conflict.

If you wanted to dial down the element power when mashing using the boil control, you may be just fine, as the PID will ramp up its duty cycle in response to the temperature drop if you are losing more power than expected from the boil control competing with the PID.

I don't know that you'll get enough leakage current through the first SSR, and IIRC an SSR needs a certain amount of voltage across the load terminals to work correctly.

The PID and boil control don't actually know if the SSRs have successfully turned on, they can only regulate their own output and assume that it is 100% effective.

Like I said though this should really be academic in practice, you will be using either the PID for mash control when you would set the boil control to 100%, or have the PID set to say 250F or 100% manual power and use the boil control for boiling. So in actual use there should be no conflict.

If you wanted to dial down the element power when mashing using the boil control, you may be just fine, as the PID will ramp up its duty cycle in response to the temperature drop if you are losing more power than expected from the boil control competing with the PID.

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

Ok, so finally heard back from Auber on their forums. The two SSR in series will work, they'll just make a bit more heat. That's no issue as I have a dual SSR heat sink mounted to the top of my control panel that's rated for 60 amps, anyway.

They also mention the switching control configuration.

Sooner or later I have to make up my mind. The sticking point for me is I'm still not entirely sure if I even *need* to control power to the element, as I'm not sure how much of a scorching issue there really is during mash recirculation/ramping temps (Multi-step mash, ramping up to mashout).

Also, since Uncle Sam owes me more than I expected, I'm in the process of ordering a stainless basket to mash/recirculate in.

They also mention the switching control configuration.

Sooner or later I have to make up my mind. The sticking point for me is I'm still not entirely sure if I even *need* to control power to the element, as I'm not sure how much of a scorching issue there really is during mash recirculation/ramping temps (Multi-step mash, ramping up to mashout).

Also, since Uncle Sam owes me more than I expected, I'm in the process of ordering a stainless basket to mash/recirculate in.

You plan will work, but you don't have to use two SSRs. When you have two SSRs in series, the heat generated by the SSRs are doubled. You can just use one SSR to drive your heating element, connect both the PID and the DSPR1's control signal to the SSR, and then use a switch to select which unit will bed connected to the SSR. You can check the wiring example 2 in page 2 of the manual of DSPR1. Or you can keep both negative wires from PID and DSPR1 connected to the SSR's pin 4, and only switch the positive wires. In addition, I would suggest you add a mechanical contactor before the hot line goes to the SSR so you can cut off the power when needed.

BeardedBrews

Well-Known Member

The sticking point for me is I'm still not entirely sure if I even *need* to control power to the element, as I'm not sure how much of a scorching issue there really is during mash recirculation/ramping temps (Multi-step mash, ramping up to mashout).

Also, since Uncle Sam owes me more than I expected, I'm in the process of ordering a stainless basket to mash/recirculate in.

I can tell you that I believe my scorching was due to the insulating effect of the grain and bag resting directly on the element. It was compounded by the fact that I regularly stir inside the bag, kicking all of the grain dust out of the mash filter and back onto the element. Since that incident I have dialed back my maximum (bag-in-contact) power to 15% on the manual PID (pulsing full 5500W power 15% of the time) and have seen no evidence of scorch, even with the bag on the element and stirring.

If you are ordering a basket, I have a hard time believing scorch would ever be an issue. I would think a simple grill or grate over the element might do the same thing.

Similar threads

- Replies

- 11

- Views

- 948

- Replies

- 6

- Views

- 893

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)