ehk089

Well-Known Member

- Joined

- Jan 8, 2018

- Messages

- 202

- Reaction score

- 168

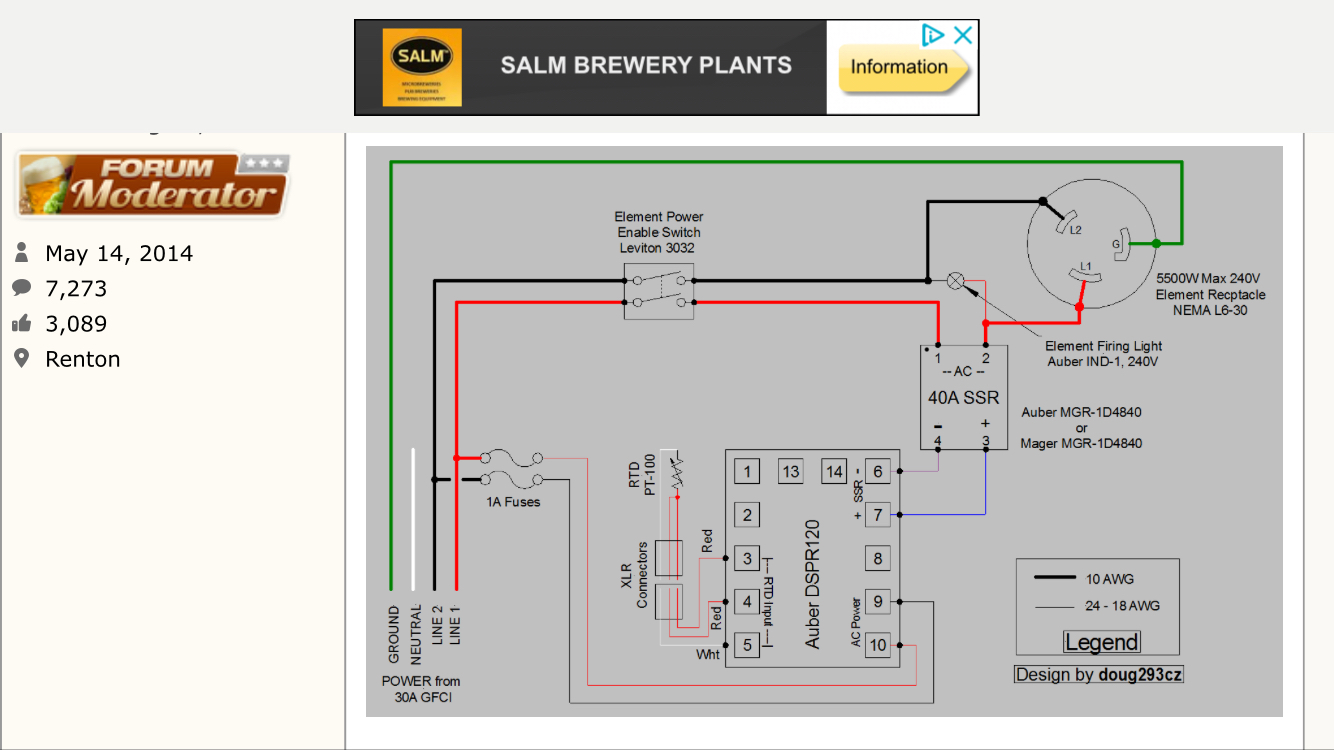

so I built a mash temp controller w a Auber ez boil on 240 running a 5500w element....I used the diagram below but omitted the fuses and the element switch. It heats great, problem is, once it heats to mash temp it keeps going up. The element runs full bore no matter if it’s reached temp or not...could it be something wrong with this wiring, or perhaps I’m not programming the controller right? Help!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)