Those are just a bit beefier than the 01’s. Use them.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New BruControl Build

- Thread starter GParkins

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

augiedoggy

Well-Known Member

The diodes worked perfect. everything is rock solid after adding them and swapping out that relay board which stopped the spike on powerup (snubber or not I still had a spike with that relay board.)

HobbyBrauer

Active Member

Is there any benefit to having multiple power supplies of varying voltages? I mean if one goes out its not like another could "fill in" for it so would there be any downside to using a cheap buck converter board for the low draw devices such as the arduino and have everything else powered by 24v?

- Joined

- Aug 7, 2014

- Messages

- 321

- Reaction score

- 182

In my case, I wanted to offload as much as I could off of the Arduino board, so I added the 5v supply to drive the RTD amplifier board and the transistor side of the three relay boards. The 12v drives the mechanical side of the relay boards, the five non-proportional motorized valves, and the Arduino. The two proportional valves and the op-amp board only run on 24v. I have access to the power supplies through my company at enough of a discount that it was an easy decision.

augiedoggy

Well-Known Member

Ive had mixed results with the cheap dc buck boost dc converters myself... it depends on the use. I settled on a 12v and 24 supply in my panel. I have a 5v din supply but in my setup it seems the rtd board is more stable if I power it off the arduino. Some of my spikes were from the grounds running from supply to supply it seems since they cleared up when eliminating them.

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

HobbyBrauer

Active Member

Okay currently I have a 24v and 12v DIN PSU in my panel the 12v only powers the MEGA, and the MEGA only powers the RTD board and wifi shield (had the same train of thought @augiedoggy about spikes). Everything else is powered by the 24v PSU; pressure sensors, pumps, valves, relay board, pH and DO transmitters, mass flow meters etc. My thinking was perhaps I could use a cheap buck converter and reduce the 24v to 12v to power the MEGA and eliminate that PSU. Then down the road I could install a MeanWell DR-UPS40 with a couple 12v batteries in series providing me with a true UPS for the entire 24v system.

Having just only main DC supply is even better for my kegerator system where otherwise I would need a 5v PSU for my Feather, a 12v for my fans, and 9v for my dehumidifier.....

Having just only main DC supply is even better for my kegerator system where otherwise I would need a 5v PSU for my Feather, a 12v for my fans, and 9v for my dehumidifier.....

- Joined

- Aug 7, 2014

- Messages

- 321

- Reaction score

- 182

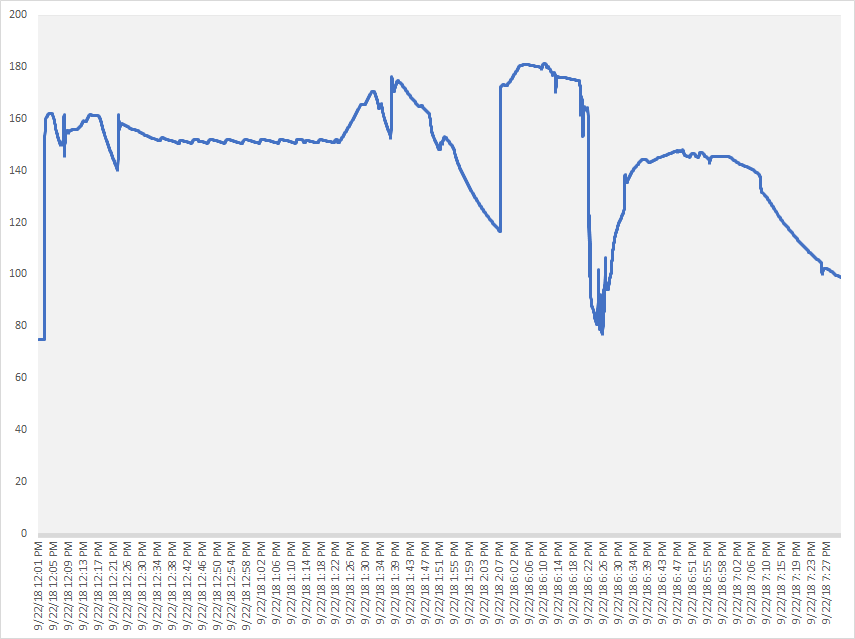

Another update: I brewed a lager (my first one!) a week ago today, christening the new fermentation chamber and newly MOV-equipped controller. I'm really happy with the 4-hour graphs I'm getting back from BruControl. It's easy for me to visualize what's been going on inside the box without running out to the garage to lift the lid and check every hour.

I have one 1-wire sensor sitting in front of the heat exchanger; another is taped to the Speidel fermenter, near the top of the liquid level. A third sensor is immersed in the glycol bath external to the box.

@BrunDog suggested I insulate the sensor that is taped to the fermenter, in order to isolate it from temperature swings inside the box. Tonight, I cut a little piece of leftover insulation board and whittled a notch for the bulb, then taped it back up to the fermenter. The attached screenshot was taken before the addition of the little foam block. I added it a couple of hours ago, and since then the temp curve for the fermenter has gotten flatter.

I may have gotten a little insulation-happy when I built the box. I bumped the temp by five degrees this morning at around 9:45 to move into a diacetyl rest for my lager. At 5:00pm, the glycol pump finally kicked in for the first time since the bump. The box is in a non-air conditioned South-facing garage, in South Florida, and it's the middle of August. I may need to re-think my fermentation schedule. I will not complain about needing to do so.

Anyway, attached is a screenshot of the behavior of the system over a 4-hour period. The Glycol chiller compressor cycles about once every 90 mins., and the pump and fans increase their cycle rate as the glycol heats up, and then go low and slow for a while after the chiller cycle completes. Ultimately, I'd like to find the optimum set point curve for the glycol reservoir that minimizes energy use across a range of temps from 32-68℉

I have to say...This is a couple of orders of magnitude better than heaving a glass carboy into a corner of the coldest closet in the house and hoping for the best.

I have one 1-wire sensor sitting in front of the heat exchanger; another is taped to the Speidel fermenter, near the top of the liquid level. A third sensor is immersed in the glycol bath external to the box.

@BrunDog suggested I insulate the sensor that is taped to the fermenter, in order to isolate it from temperature swings inside the box. Tonight, I cut a little piece of leftover insulation board and whittled a notch for the bulb, then taped it back up to the fermenter. The attached screenshot was taken before the addition of the little foam block. I added it a couple of hours ago, and since then the temp curve for the fermenter has gotten flatter.

I may have gotten a little insulation-happy when I built the box. I bumped the temp by five degrees this morning at around 9:45 to move into a diacetyl rest for my lager. At 5:00pm, the glycol pump finally kicked in for the first time since the bump. The box is in a non-air conditioned South-facing garage, in South Florida, and it's the middle of August. I may need to re-think my fermentation schedule. I will not complain about needing to do so.

Anyway, attached is a screenshot of the behavior of the system over a 4-hour period. The Glycol chiller compressor cycles about once every 90 mins., and the pump and fans increase their cycle rate as the glycol heats up, and then go low and slow for a while after the chiller cycle completes. Ultimately, I'd like to find the optimum set point curve for the glycol reservoir that minimizes energy use across a range of temps from 32-68℉

I have to say...This is a couple of orders of magnitude better than heaving a glass carboy into a corner of the coldest closet in the house and hoping for the best.

- Joined

- Aug 7, 2014

- Messages

- 321

- Reaction score

- 182

Tonight's update is about an extraordinary opportunity I had today, to sit at the foot of the throne at Casa @BrunDog for an early morning brew. I'm going to cover some of the notes I took.

To start with, some hardware context is probably important:

@BrunDog's rig is different than mine, in that he's using a 2-vessel RIMS setup, while I opted for a 3-vessel HERMS rig. The difference? At the end of the day, the water jugs he fills and heaves to the top of the brewstand rack are (in essence) a Cold Liquor Tank, but his RIMS rig certainly appears to shorten the ramp times over what I've measured on my rig. It's hard to tell how much of that is due to batch size difference vs. the RIMS/HERMS debate. My takeaway is that I'll bet I'd be happier if I had a 5500W RIMS tube that I could use as valve-selectable booster heat for either the HLT or the boil kettle. I came away convinced that a 30-gallon kettle is at the upper limit of the capability of a single 5500W element. For efficient multi-batch brew days, my ideal configuration would probably be a 100A panel with a 5500W immersed element and a 5500W RIMS tube for both the HLT and BK. If I were to do that, I would definitely offload the heavy power components to a separate enclosure.

Aonther feature of @BrunDog's rig that I intend to implement as soon as possible is his fresh water manifold. Between filling kettles, rinsing mash paddles, cooling boiling wort, making a batch of sanitizer, and a hundred other uses, having a single hookup to a garden hose makes the brew day several orders of magnitude simpler. A self-coiling hose attached to the brew stand, an inlet to the cleanup cycle, a driveway washdown hose, and (with filtration) a pot-filling supply all take away a tedious list of manual steps to get to the right kind of water needed on brew day.

While I don't see it on my radar in current planning, @BrunDog has invented (and already had shamelessly knocked off) a very nice steam condenser that allows a full boil cycle with the kettle lid firmly seated, with nothing but a trickle of waste water to show for it. He's got a separate thread on it, Here. I saw it in action today, and it works very well. It's one of the consumers off of his garden hose manifold, and it doesn't seem to affect pressure or flow for any of the other draws off of the manifold.

The last hardware that I'd like to review is his two-stage wort chiller. With little fuss, no muss, and two 10-lb. bags of ice, I saw a batch of wort come out of a boil kettle at 170+ and go into a fermenter at 65℉. That's no small feat, given the tap water was coming out of the hose at 85℉+. The trick is to use the garden hose water to accomplish the first stage of cooling to 85℉ or so, and then route the semi-chilled wort through an icy-cold loop with some temperature sensing and flow control, so that the final output into the fermenter is at a precise, controlled pitching temperature.

All in all, the rig seemed very well-organized, and was obviously dialed in and useful. It was nice to pick up some pointers and hacks, as I'm just getting organized with my new rig. What was eye-popping was what he'd done with the app. Understandable, since it's his app, but eye-popping nonetheless. I spent the trip home with the dawning realization that the only fundamental difference between @BrunDog's implementation and mine was the use of scripts. But oh, what a difference!

First off: @BrunDog created a separate Workspace where the recipe-specific parameters get entered. Water volumes, mash steps, mash temps, sparge volumes, hop addition timing, etc., etc. Everything came off of a Beersmith printout, and was set up to be entered in the same sequence as it appeared in the printout. The underpinnings of that capability are based on a script where all of the recipe-specific stuff is a defined variable. The script doesn't have to be edited for each recipe. In his case, everything from strike volume through pitch temperature is a variable that gets plugged in before the first valve opens. I got busy with my own system as soon as I got home, while it was fresh in my mind.

Here's what I have so far:

The second thing that was really cool was the separate scripts for rinsing and cleaning the rig. He's got his system set so that the rinsing script that runs at the beginning and at the end of the cleanup process is open loop (hose water comes into the process and goes down the driveway), but the hot PBW script cycle that runs in the middle of the process is closed loop, where a fixed amount of soapy water is heated, sprayed, and recirculated. (hardware observation: CIP sprayers are critical).

All in all, it was a really great learning experience. There's nothing like seeing the scripting in action. Hat tip to @BrunDog for the huge extra mile in customer service.

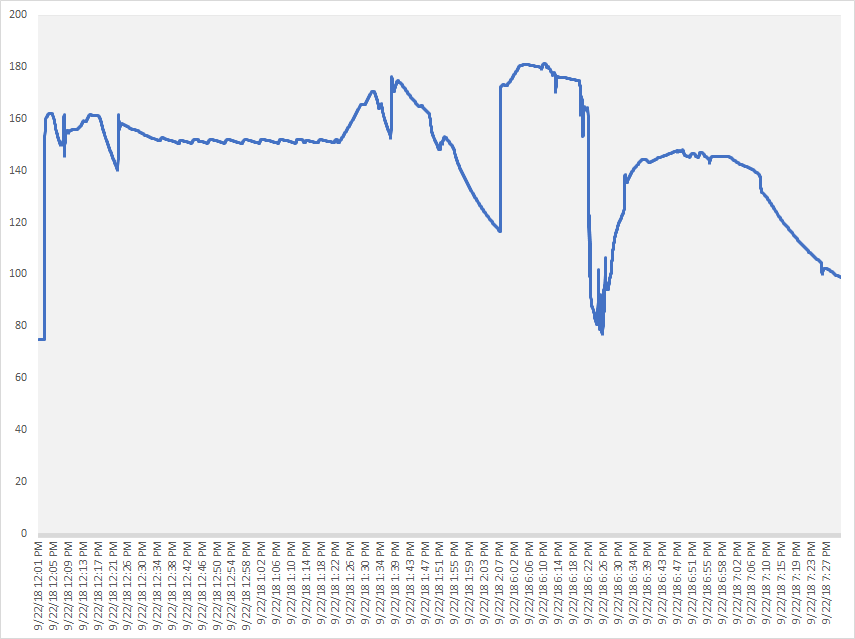

In other news, the new ferm chamber is doing very well. The graphs in the pic below are over a four-hour span. While the middle graph of the fermenter temp may seem a little spikey, a close look at the Y-axis on the left shows the oscillation spanning about 2℉. Not bad for a hot-assed garage in August:

Tomorrow is the end of the diacetyl rest and the start of a ramp-down to lagering temps. That will be the acid test, for sure.

To start with, some hardware context is probably important:

@BrunDog's rig is different than mine, in that he's using a 2-vessel RIMS setup, while I opted for a 3-vessel HERMS rig. The difference? At the end of the day, the water jugs he fills and heaves to the top of the brewstand rack are (in essence) a Cold Liquor Tank, but his RIMS rig certainly appears to shorten the ramp times over what I've measured on my rig. It's hard to tell how much of that is due to batch size difference vs. the RIMS/HERMS debate. My takeaway is that I'll bet I'd be happier if I had a 5500W RIMS tube that I could use as valve-selectable booster heat for either the HLT or the boil kettle. I came away convinced that a 30-gallon kettle is at the upper limit of the capability of a single 5500W element. For efficient multi-batch brew days, my ideal configuration would probably be a 100A panel with a 5500W immersed element and a 5500W RIMS tube for both the HLT and BK. If I were to do that, I would definitely offload the heavy power components to a separate enclosure.

Aonther feature of @BrunDog's rig that I intend to implement as soon as possible is his fresh water manifold. Between filling kettles, rinsing mash paddles, cooling boiling wort, making a batch of sanitizer, and a hundred other uses, having a single hookup to a garden hose makes the brew day several orders of magnitude simpler. A self-coiling hose attached to the brew stand, an inlet to the cleanup cycle, a driveway washdown hose, and (with filtration) a pot-filling supply all take away a tedious list of manual steps to get to the right kind of water needed on brew day.

While I don't see it on my radar in current planning, @BrunDog has invented (and already had shamelessly knocked off) a very nice steam condenser that allows a full boil cycle with the kettle lid firmly seated, with nothing but a trickle of waste water to show for it. He's got a separate thread on it, Here. I saw it in action today, and it works very well. It's one of the consumers off of his garden hose manifold, and it doesn't seem to affect pressure or flow for any of the other draws off of the manifold.

The last hardware that I'd like to review is his two-stage wort chiller. With little fuss, no muss, and two 10-lb. bags of ice, I saw a batch of wort come out of a boil kettle at 170+ and go into a fermenter at 65℉. That's no small feat, given the tap water was coming out of the hose at 85℉+. The trick is to use the garden hose water to accomplish the first stage of cooling to 85℉ or so, and then route the semi-chilled wort through an icy-cold loop with some temperature sensing and flow control, so that the final output into the fermenter is at a precise, controlled pitching temperature.

All in all, the rig seemed very well-organized, and was obviously dialed in and useful. It was nice to pick up some pointers and hacks, as I'm just getting organized with my new rig. What was eye-popping was what he'd done with the app. Understandable, since it's his app, but eye-popping nonetheless. I spent the trip home with the dawning realization that the only fundamental difference between @BrunDog's implementation and mine was the use of scripts. But oh, what a difference!

First off: @BrunDog created a separate Workspace where the recipe-specific parameters get entered. Water volumes, mash steps, mash temps, sparge volumes, hop addition timing, etc., etc. Everything came off of a Beersmith printout, and was set up to be entered in the same sequence as it appeared in the printout. The underpinnings of that capability are based on a script where all of the recipe-specific stuff is a defined variable. The script doesn't have to be edited for each recipe. In his case, everything from strike volume through pitch temperature is a variable that gets plugged in before the first valve opens. I got busy with my own system as soon as I got home, while it was fresh in my mind.

Here's what I have so far:

The second thing that was really cool was the separate scripts for rinsing and cleaning the rig. He's got his system set so that the rinsing script that runs at the beginning and at the end of the cleanup process is open loop (hose water comes into the process and goes down the driveway), but the hot PBW script cycle that runs in the middle of the process is closed loop, where a fixed amount of soapy water is heated, sprayed, and recirculated. (hardware observation: CIP sprayers are critical).

All in all, it was a really great learning experience. There's nothing like seeing the scripting in action. Hat tip to @BrunDog for the huge extra mile in customer service.

In other news, the new ferm chamber is doing very well. The graphs in the pic below are over a four-hour span. While the middle graph of the fermenter temp may seem a little spikey, a close look at the Y-axis on the left shows the oscillation spanning about 2℉. Not bad for a hot-assed garage in August:

Tomorrow is the end of the diacetyl rest and the start of a ramp-down to lagering temps. That will be the acid test, for sure.

Last edited:

Hi @GParkins,The last thing I did was to plug the power cord in and start running some continuity checks for ground. I clipped one test lead to a door latch, and started probing around. i was most concerned about the kettles, but they have 0Ω resistance to the latch. Same with everything I checked, except...

I'm going to have to run a bunch of green jumpers all over the place to ground the rack. It has these stupid little plastic wedges that set the shelf height. Unfortunately, the manufacturer didn't have the common damn courtesy to use conductive wedges, so now I have to run jumpers to each leg and to each shelf. I may cheat and just drill and tap the legs, and use a nut/bolt/fender washer clamp for the shelves. Tacky and ugly, but effective. And better than flopping around on the garage floor, wishing I could administer an AED to myself.

Curious if you have any pictures of how you grounded your wire shelves. I'm planning on using a wire shelving unit as you did, and they all seem to come with the same plastic sleeves, isolating each shelf and leg. Some conductive shelf sleeves exist, but they're pretty expensive and hard to get. My thought is similar to the one you described here--drilling into each leg and tying a ground wire to each shelf. Ugly, yes, but better than the alternative.

Thanks,

-Adam

- Joined

- Aug 7, 2014

- Messages

- 321

- Reaction score

- 182

No pics, but there is an added benefit of drilling and tapping: If you run a screw into the leg just below the plastic inserts, you have an emergency backup if one of the little inserts fails with a kettle full of boiling wort.

just_looking

Member

- Joined

- Dec 28, 2016

- Messages

- 9

- Reaction score

- 0

Hi @GParkins -

I followed your build and just completed a similar HERMS build.

I’m having issues with my PID setup. I’m using the defaults as suggested by Brundog (30-1-5) but it doesn’t seem to be working as I would expect.

As the PID approaches the desired temp is doesn’t reduce the power and overshoots the temp. What are you using for your PID settings?

I followed your build and just completed a similar HERMS build.

I’m having issues with my PID setup. I’m using the defaults as suggested by Brundog (30-1-5) but it doesn’t seem to be working as I would expect.

As the PID approaches the desired temp is doesn’t reduce the power and overshoots the temp. What are you using for your PID settings?

What is the size of your mash (in actual liquid amount), what is the size of your HERMS (in actual liquid amount), how fast would you guestimate you are recirculating, and how much power if the HLT operating with?

One quick tip is to limit the max integral to 50%, or even lower.

One quick tip is to limit the max integral to 50%, or even lower.

just_looking

Member

- Joined

- Dec 28, 2016

- Messages

- 9

- Reaction score

- 0

My mash was 5 gallons of water with 9 pounds of grain in a 20 gallon kettle and my herms was 8 gallons of water in a 15 gallon kettle. I would guess I’m circulating at approximately 12 quarts a minute (I’m putting in a flow meter today). The HLT is using a 5500 watt heating element.

Could you post up a graph of the mash temp? You can create it if you go back in time.

Also, where is the temp probe located that the PID is referencing?

Also, where is the temp probe located that the PID is referencing?

just_looking

Member

- Joined

- Dec 28, 2016

- Messages

- 9

- Reaction score

- 0

Here is the graph. The temp probe is on my MLT measuring the output from the herms coil as it enters the MLT. Looking at it graphically it doesn't look like such a wide temp swing. I was trying to mash at 150. This was my first run so I learned a ton from it. Just want to make sure my settings are appropriate.

Looks like some massive temp swings... can't tell the peaks and valleys there, but I am suspecting they are high. Can you look to see how high and low by removing the fixed range of the graph?

That said, this may be noise or a loose connection. A curve should have no dramatic variation over time. The interface's algorithms will respond to noise as part of the signal. If you send us the data file from this time frame, we can look at that in more detail.

What temp sensors are you using?

That said, this may be noise or a loose connection. A curve should have no dramatic variation over time. The interface's algorithms will respond to noise as part of the signal. If you send us the data file from this time frame, we can look at that in more detail.

What temp sensors are you using?

just_looking

Member

- Joined

- Dec 28, 2016

- Messages

- 9

- Reaction score

- 0

Email the configuration file (.brucfg) and all the files from the particular day of interest. State the name of the temp probe in the email.

just_looking

Member

- Joined

- Dec 28, 2016

- Messages

- 9

- Reaction score

- 0

Email sent to brucontrol info address.

Hi @just_looking... thanks for sending the file. Here is the graph I pulled out from 12:00pm to 7:30pm that day for the device "Mash Temp".

I'm not sure where the problem is that you are saying. I see what looks to be normal-ish cycling over the course of time between 12:30 and 1:30. The temps reported here are swinging from 150.65 to 152.20. Above you said 150, so this is slightly higher than that.

It looks like you are using an RTD sensor with normal calibration, and this sensor "Mash Temp" drives the "HLT Heat PID". Where is this sensor mounted - at the exit of the HERMs or somewhere else? Was is set for 150?

I'm not sure where the problem is that you are saying. I see what looks to be normal-ish cycling over the course of time between 12:30 and 1:30. The temps reported here are swinging from 150.65 to 152.20. Above you said 150, so this is slightly higher than that.

It looks like you are using an RTD sensor with normal calibration, and this sensor "Mash Temp" drives the "HLT Heat PID". Where is this sensor mounted - at the exit of the HERMs or somewhere else? Was is set for 150?

just_looking

Member

- Joined

- Dec 28, 2016

- Messages

- 9

- Reaction score

- 0

Hi @BrunDog - I appreciate you looking at the file. I checked my variables in my script and my mash temp was set at 150. The exit of the HERMS goes directly to a tee on the MLT. The "Mash Temp" sensor is mounted in that tee. I'll be brewing again this weekend and I'll watch the process a little closer.

augiedoggy

Well-Known Member

Maybe tweaking the P I D values will help a bit to help with any overshoot? regardless a degree or so swing is kind of normal.

Just posting to follow this interesting thread...

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 16

- Views

- 2K

- Replies

- 1

- Views

- 644

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)