So here I sit with about 25 minutes left in the mash on what should be a relaxed brew day. But the Beer Gods frowned on me early in the process when without warning my grain crusher went Tango Uniform on me about half way through my 12 pound crush.

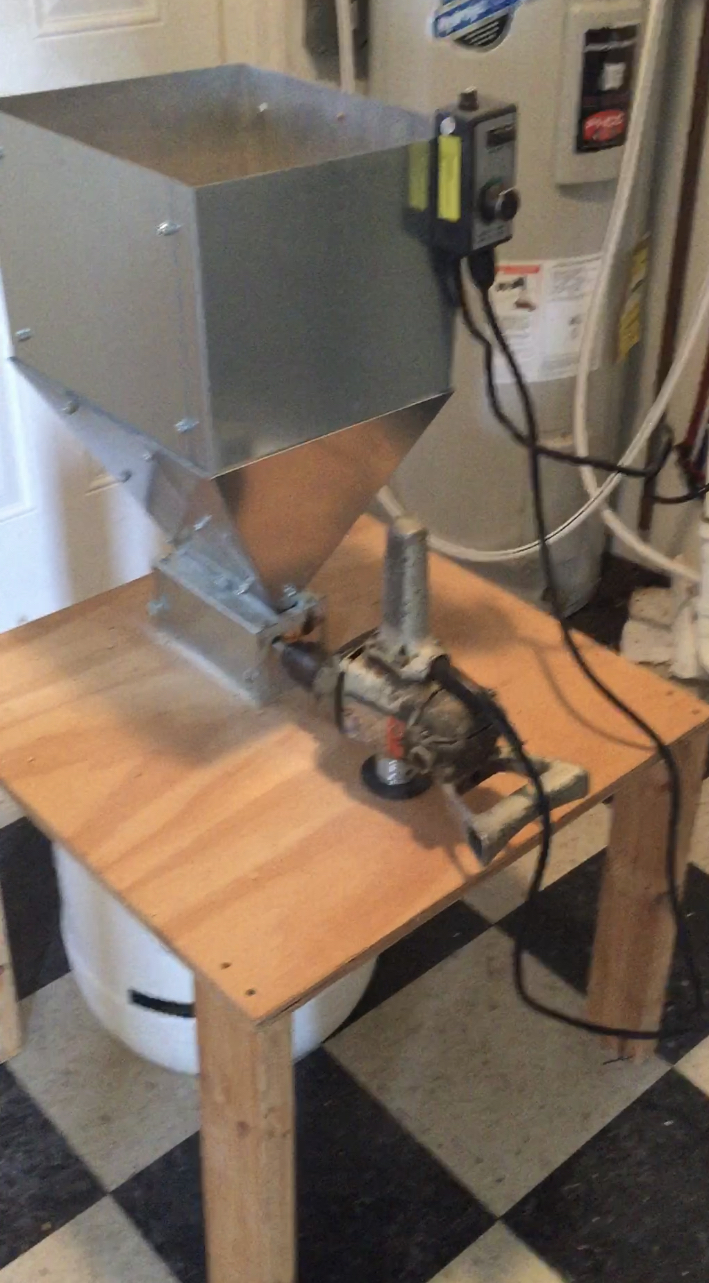

You know how you take some things totally for granted? Well that's how I thought about my mill. It's a Barley Crusher that I got back in 2008 according to the shipping invoice. It's just a tool, like a hammer, that I never gave much thought to. Until I needed to pound something.

I finally limped through a "crush", though it remains to be seen what my efficiency ends up being. Bottom line, SWMBO'd gave prior approval on my loan application to get a new one.

I remember a thread maybe 6 months ago talking about peoples' favorite crushers. Any feedback or regrets from what y'all have purchased? I've been mostly happy with the Barley Crusher even though their was a fair amount of displeasure with them from other owners who commented on the previous thread. I don't want to spend an arm OR a leg on a new one but I do brew at least 15-20 times a year, so I'm not averse to spending $$$ for quality.

Suggestions?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)