So of course, after all the good research I picked my brew rig steel... 1.5''x1.5'', unknown gauge... haha I know I know.

So my buddy got a hold of some industrial square tubing (railing) at a job site that was being scrapped. He cut it up on site and hauled it home and now we have free steel for the project!! I am not sure of the gauge yet, but my buddy is welder and he said it was probably around 14g or so, but more than heavy enough for our application.

In other developments, we decided that a tippy dump for the MT is mandatory. Already been drawing up a cradle/basket design that will use pillow block bearings to hold a steel bar that will be welded to the basket that holds the MT.

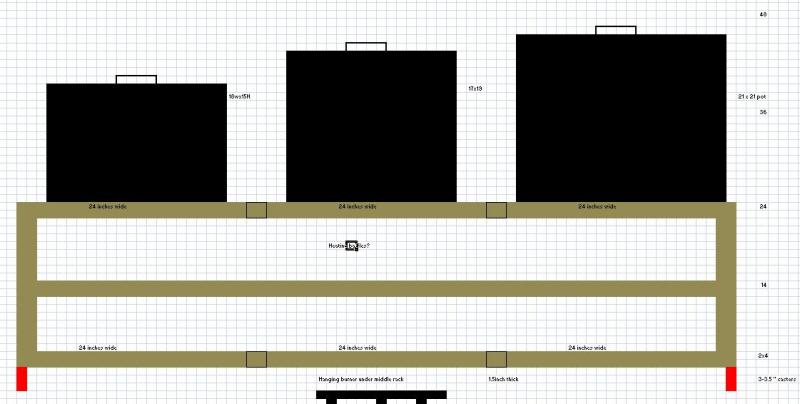

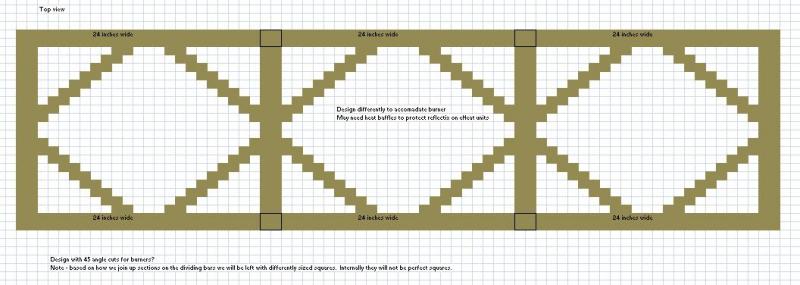

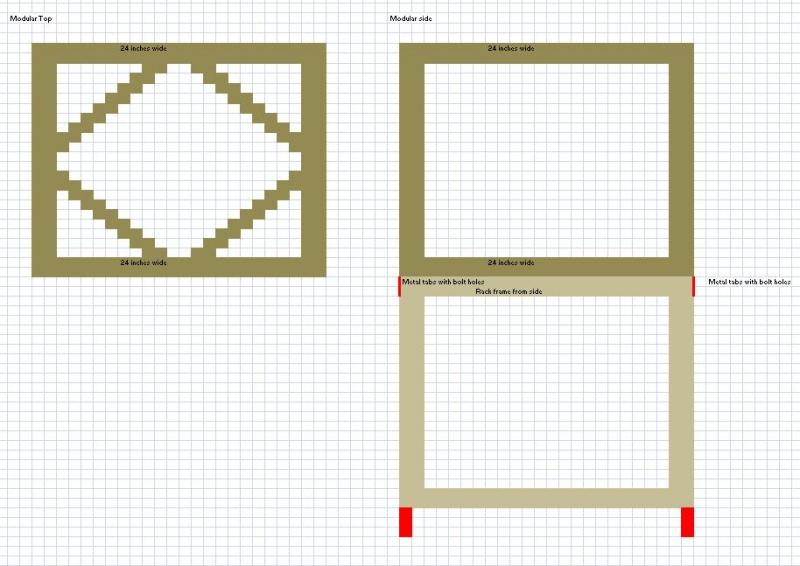

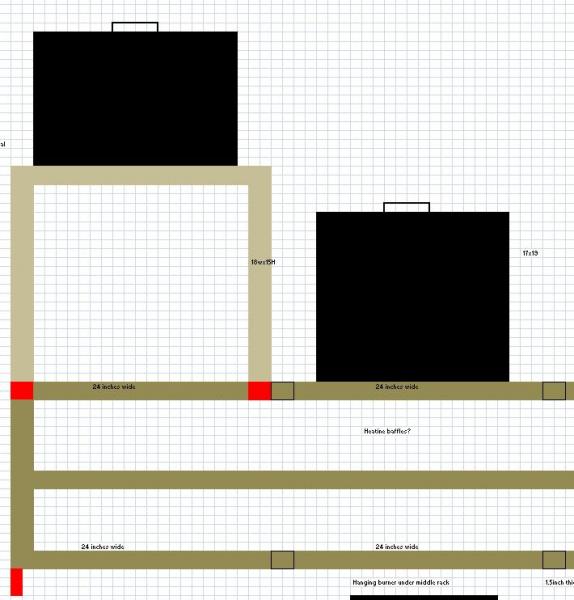

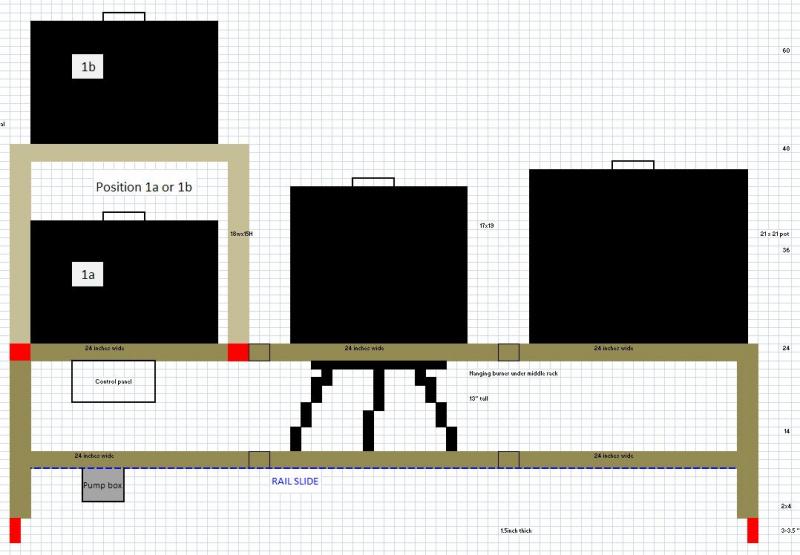

We are still trying to decide on the final design for the stand (single or two tier). Hopefully this weekend we can make some headway, since now we have some steel to play with! Looks like a brew day with design in mind

Jon - Glad to hear that baout your pump set up. I had heard that the 90 degree bend had caused some issues for some people so I had been debating adding 2.5 or so inches of straight pipe to the inlet and outlet and then 2 45's (or something like that).

Are your pumps the center inlet type? or the side inlet type? can't recall what the other type is. I was thinking of grabbing mine from rebel brewer.

http://www.rebelbrewer.com/shoppingcart/search.php?search_query=march&x=0&y=0

wasn't sure if the march was the way to go, or the chugger.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)