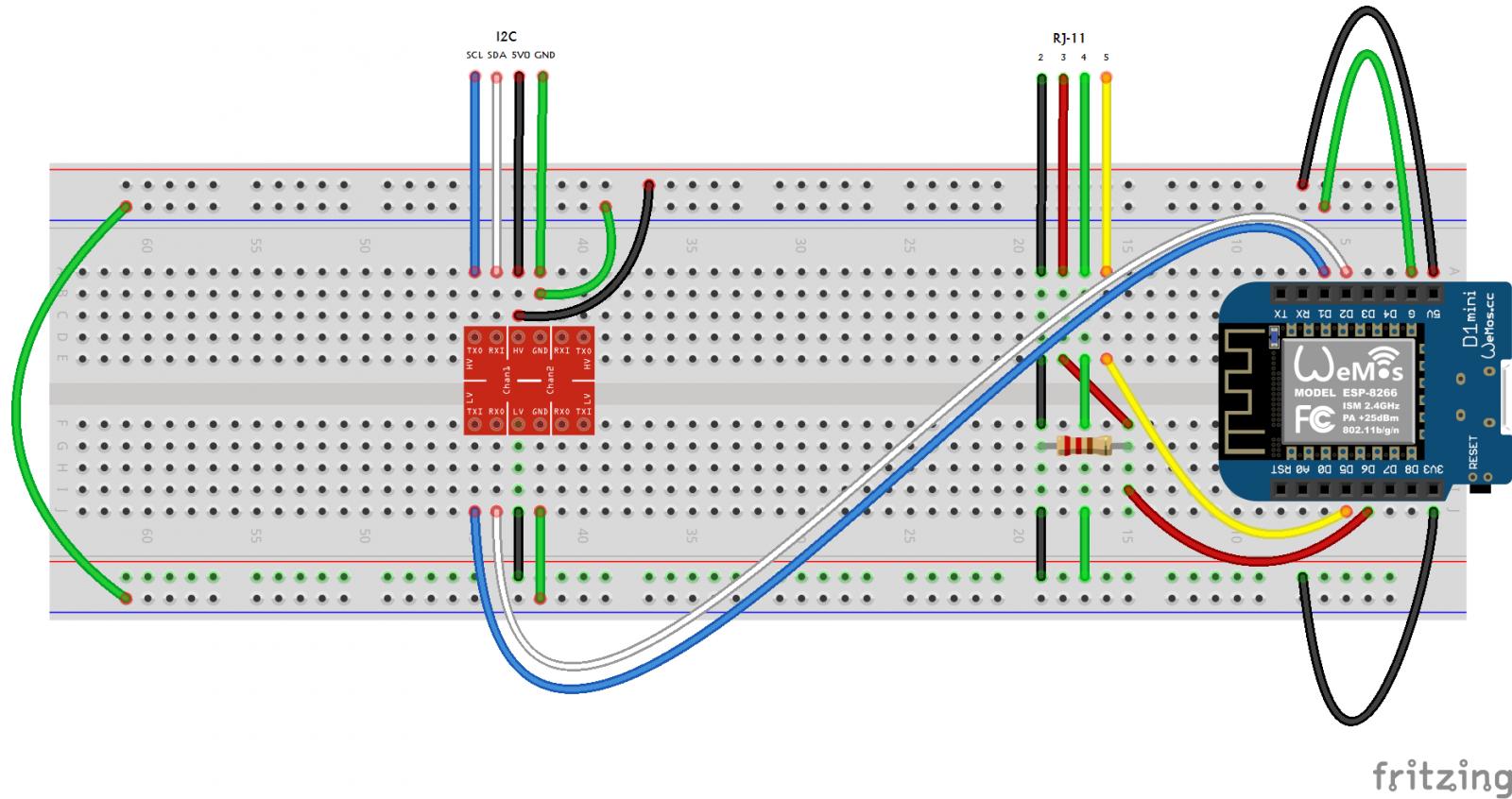

So pin wise between Thorrak and Pocketmon we have

Pin Number Pocketmon Thorrak

GPIO0 - D3 - Pocketmon, Door (not used)* - Thorax, Buzzer (not supported)

GPIO2 - D4 - Pocketmon, rotary pin PushDown - Thorax, N/C

GPIO13 - D7 - Pocketmon, rotary pin B - Thorax, Door (untested)

GPIO15 - D8 - Pocketmon, rotary pin A - Thorax, N/C

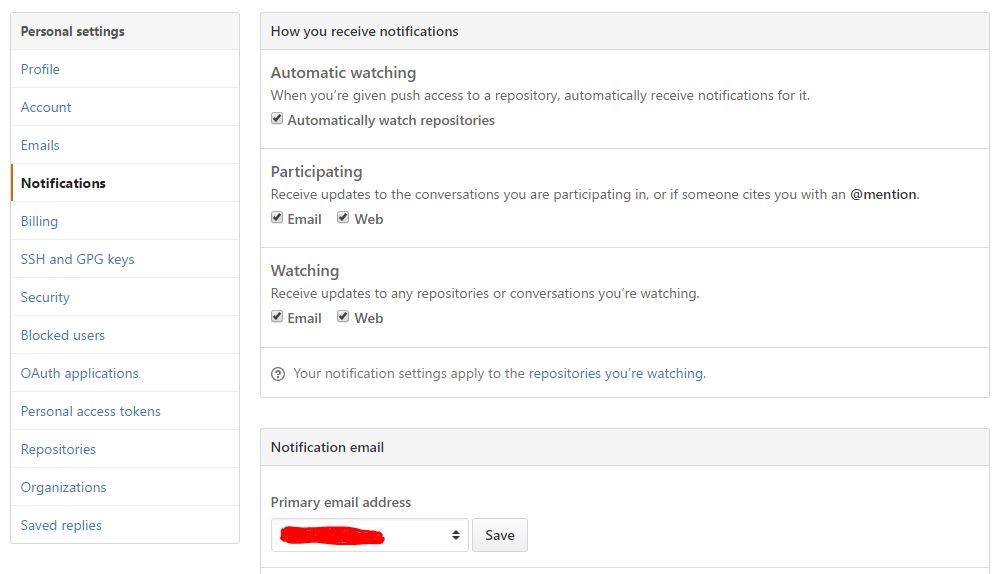

Pin Function ESP-8266 Pin

TX TXD TXD

RX RXD RXD

A0 Analog input, max 3.3V input A0

D0 IO GPIO16

D1 IO, SCL GPIO5

D2 IO, SDA GPIO4

D3 IO, 10k Pull-up GPIO0

D4 IO, 10k Pull-up, BUILTIN_LED GPIO2

D5 IO, SCK GPIO14

D6 IO, MISO GPIO12

D7 IO, MOSI GPIO13

D8 IO, 10k Pull-down, SS GPIO15

G Ground GND

5V 5V -

3V3 3.3V 3.3V

RST Reset RST

I'm learning as i'm going along here, but am i right in thinking if i choose to remove the buzzer and door function (they're of no use to my set up)

I could map the following

D4 as Rotary Push down

D3 changes from unused/untested to Rotary Pin B

D8 Rotary Pin A

This would mean door function still in place on the original function and really the only change is to pin D3, as the rest are using unused pins, and does anyone have a buzzer?

As i say i'm learning as i'm going along with this, and the only constant i can see in these GPIO is the IO (

http://www.wemos.cc/Products/d1_mini.html) i realise there could be a potential reset issues but i guess i've just got to try it out.

Now i just need to find the files to cut and paste/edit and (i'm assuming its just the one that we use to flash the ESP8266, and then i just need to wait for the replacement chip to arrive and hope this one works for more than 5 mins,

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)