Tripod

Well-Known Member

Wow, ChillyP that looks great! I'm getting stir-plate envy over here! :cross:

LHBS or scientific suply store. I got mine at Midwest. They have 1" and 2".I'm sorry if this is on here, but I couldn't find it. Where is everyone getting their stir stick.

Cheers,

Jeremy

LHBS or scientific suply store. I got mine at Midwest. They have 1" and 2".

Ditto, using a 2". Most expensive part of the project.

I have a 2" also but I think it's causing me problems. I find that it gets off center easily and gets thrown a lot. I'm using a 1.5L coffee press as a vessel.

What an idea! In my travels I worked for a failed dot.com and when we closed we raffled off the kitchen supplies and I won the Starbucks french press. I might have a starter vessel and didn't know it!!

Do you think you stir bar issues are due the french press vessel or fan speed

Hopefully not a stupid question but do you really need to glue the hard drive magnet to the steel washer? My magnet feels firmly attached to the steel washer on it's own. Will influence from the stir bar be strong enough to move the magnet from it's location on the fan?

Thanks so much to Tony for posting this. With parts and instructions even an all thumbs guy like me can build this (and I did Wooo Hooo!!)

Claudius, what are the +/- orientation of the magnets?

++--?

Claudius's is similar to mine. I use 4 magnets across in a line, --++. I have had the most success with this orientation

Great idea!I'm going to start going through this thread to post different magnet setups people have used that have been successful in my original post.

LHBS or scientific suply store. I got mine at Midwest. They have 1" and 2".

Claudius's is similar to mine. I use 4 magnets across in a line, --++. I have had the most success with this orientation. It greatly reduces the tenancy of the plate to throw the stir bar at high speeds.

I think part of the problem I'm seeing is that the hard drive magnets are curved so it's difficult to find the center of the magnet and balance on the fan. I found that if I used a single curved magnet with a 2" stir bar, which is longer than the magnet, the bar would not center over the magnet - it kinda favored one end of the magnet. I had to add a second curved magnet to make it longer than the stir bar and it centered. This, however, made it more difficult to find the center of the magnet to balance on the fan.

I think there might be a difference between the "magnetic" center, which the stir bar requires for balance, and the "rotational" center, which the fan requires for balance. If these two points aren't the same, there's going to be problems. I'm not sure they are with this set up.

I'm thinking the stir bar is my problem but I'm not sure. I tried different fans, many power supplies and many magnets. It works most of the time with deep vortex but I have to play with it a bit. It's not consistent.

I bit the bullet and ordered a 1" stir bar from midwest to test. The french press vessel seems to work fine. Bottom is nice and flat. It might even be pyrex so I can boil and chill without transfer but I don't want to risk it if I'm wrong.

I'm wondering if the flasks have slightly concave bottoms so the stir bar auto-balances and spins better due to less friction ....

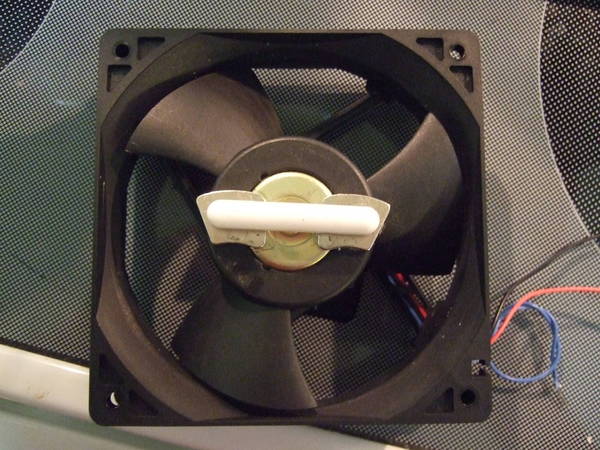

Here's my build:

Hey man, nice job! I got my stirplate up and running the other day and this was a great help, cheers!

Power Switch Wiring

Assuming everything has been done correctly, plug in your power supply, flip your power switch to the “On” position, and try turning the knob on the potentiometer back and forth. You should be able to observe the fan speeding up and slowing down as you turn the knob back and forth.

Now, we need to take the steel washer and glue it onto the fan. I used some 60 second epoxy so that I could turn the fan on and off to observe if the washer was centered on the center of the fan.

The next steps in this project is to fine tune the positioning of the fan within the enclosure, and try magnet combinations and positions until you get your bar spinning correctly.

I used 2 ½ inch 10/32 bolts with matching nuts and washers to mount my fan. I also used some ¾ inch stand offs to raise the fan. Instead of the standoffs, you can use extra 10/32 nuts to position the fan up and down the bolts. I also found that you need to drill out the holes of the fan to get the bolts through. 8/32 bolts will work without drilling.

Mounted Fan

Bottom Side of Aluminum plate with fan mounted and secured.

Your project enclosure should have come with both an aluminum and a plastic sheet to close up the enclosure. I drilled out the pattern for my fan's mounting holes into my aluminum sheet, and then mounted the fan. Once I had everything drilled out and mounted, I put every thing together, and tried it out...

Good Luck!!!

Also, for all you other DIY'ers, let me know if you catch a mistake or typo on here so I can edit...