goatchze

Well-Known Member

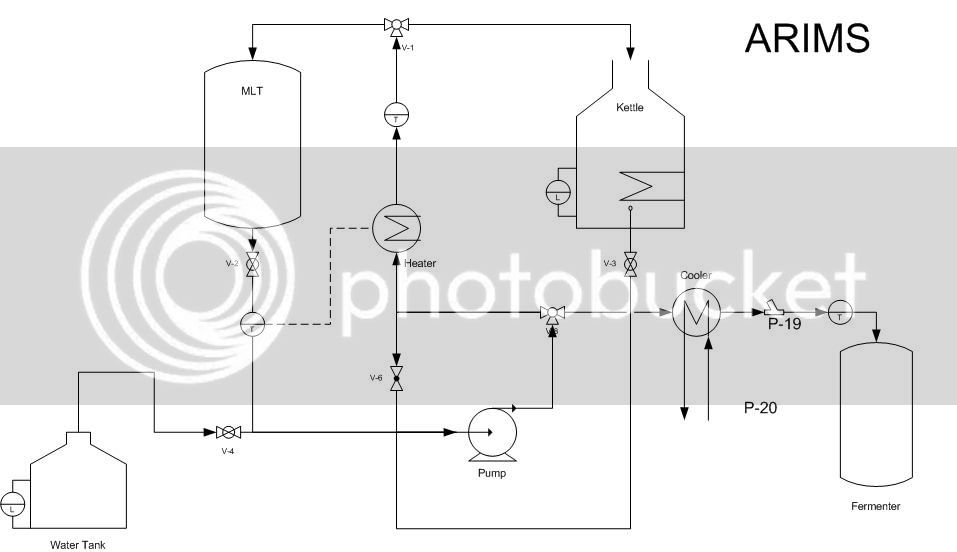

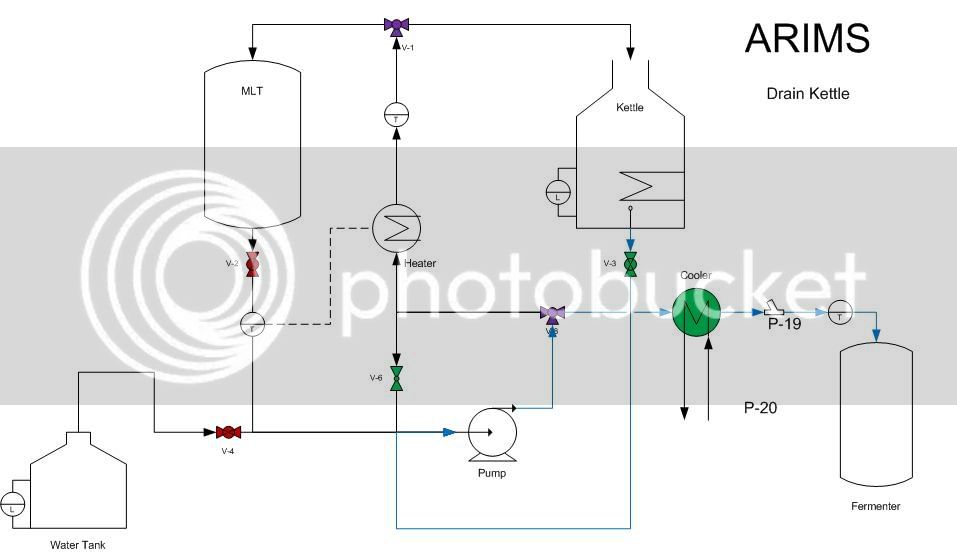

So I've been dreaming of setting up a RIMS system and, after looking at a few other designs, here is what I've come up with.

My goal is to have a system that eliminates the need for an HLT. I want to minimize the space required, so I want to stick with only the MLT and the brew kettle.

One thing that I have left off in the drawing, I intend to put a globe valve on the pump discharge to be able to throttle the outlet pressure/flow. I do not intend to put the recirculation loop back to the pump suction unless it is required (I don't know what the pump's curve looks like nor have I sized the heating element).

I also intend to put in sample points at the bottom of the MLT and downstream of the CFC.

The plan of operation is this:

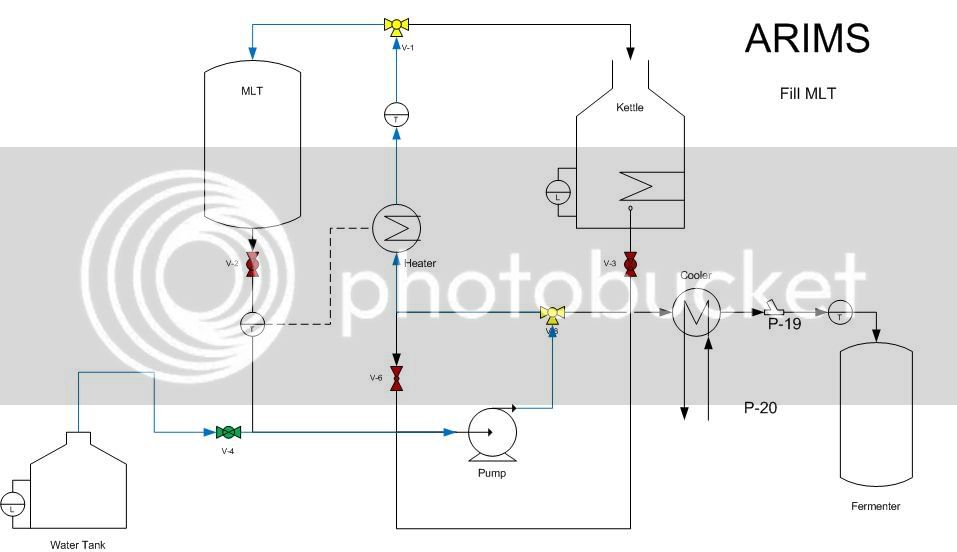

Step 1: Fill MLT

Valve V-2 is closed, Valve V-4 is open, Valve V-8 is set to left, Valve V-1 is set to left. I run like this until I have drawn out the desired amount of water from my water tank. I intend to have a bypass for the T controller and have the heating element on full during fill.

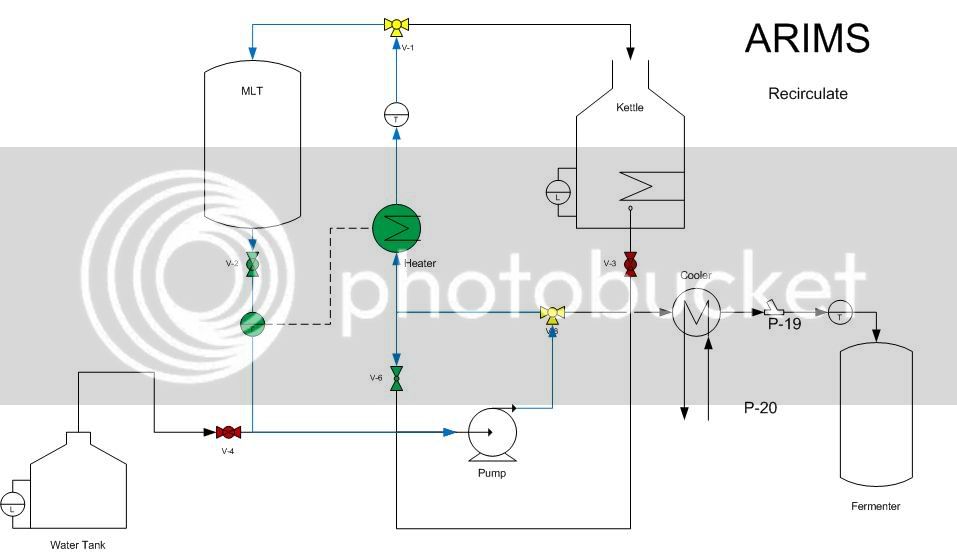

Step 2: Recirculate wort.

Valve V-4 is closed and V-2 is opened. The T controller is turned on and wort is recirculated at desired temperatures and times.

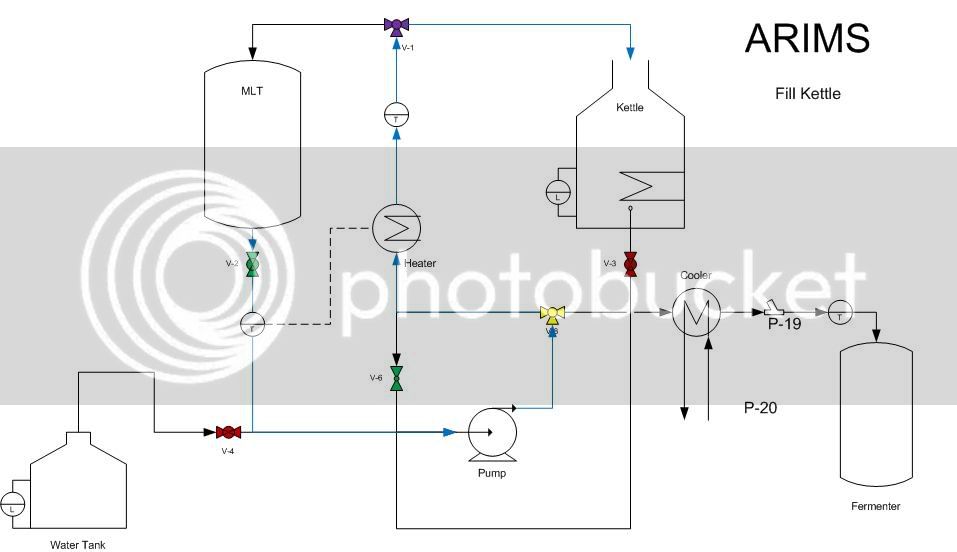

Step 3: Drain MLT/Fill Kettle

Valve V-1 set to right, Valve V-3 is closed. Wort is pumped out of MLT and into Kettle. Kettle set to heat.

Step 4: Sparge

Repeat steps 1, 2, 3 with sparge water

Step 5: Boil

Step 6: Drain Kettle

Valve V-3 set open, V-8 set to right. Cooling water set on (CFC). Wort is pumped out of kettle, through CFC, through aerator, and into fermenter.

What are your thoughts??? Has anyone tried to sparge like this?

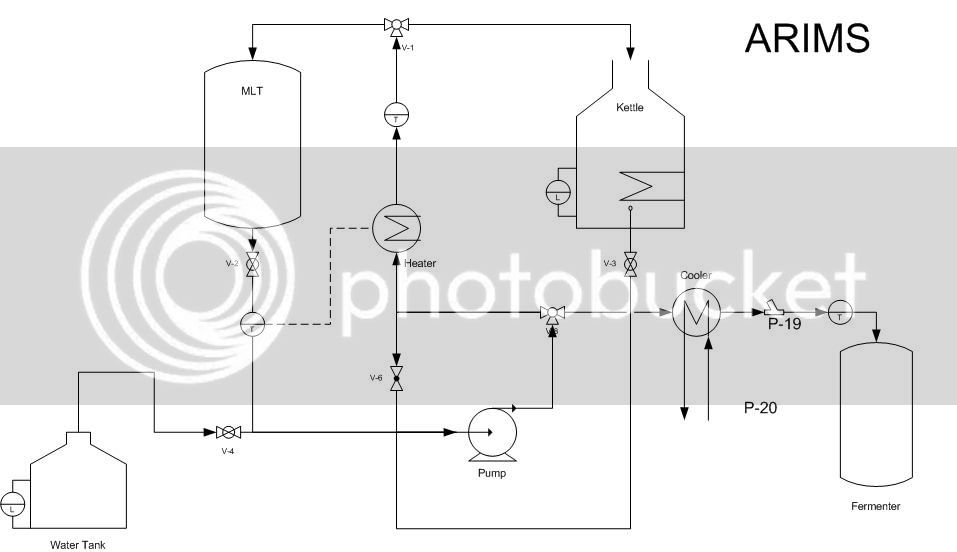

My goal is to have a system that eliminates the need for an HLT. I want to minimize the space required, so I want to stick with only the MLT and the brew kettle.

One thing that I have left off in the drawing, I intend to put a globe valve on the pump discharge to be able to throttle the outlet pressure/flow. I do not intend to put the recirculation loop back to the pump suction unless it is required (I don't know what the pump's curve looks like nor have I sized the heating element).

I also intend to put in sample points at the bottom of the MLT and downstream of the CFC.

The plan of operation is this:

Step 1: Fill MLT

Valve V-2 is closed, Valve V-4 is open, Valve V-8 is set to left, Valve V-1 is set to left. I run like this until I have drawn out the desired amount of water from my water tank. I intend to have a bypass for the T controller and have the heating element on full during fill.

Step 2: Recirculate wort.

Valve V-4 is closed and V-2 is opened. The T controller is turned on and wort is recirculated at desired temperatures and times.

Step 3: Drain MLT/Fill Kettle

Valve V-1 set to right, Valve V-3 is closed. Wort is pumped out of MLT and into Kettle. Kettle set to heat.

Step 4: Sparge

Repeat steps 1, 2, 3 with sparge water

Step 5: Boil

Step 6: Drain Kettle

Valve V-3 set open, V-8 set to right. Cooling water set on (CFC). Wort is pumped out of kettle, through CFC, through aerator, and into fermenter.

What are your thoughts??? Has anyone tried to sparge like this?