On the FB site people mentioned the idea of needing to secure the hop cages using the rubber gaskets so they don't open. Has anyone had this issue? Not me - and I have never used them...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Picobrew Thread

- Thread starter Baja_Brewer

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Physicsbrewer

Active Member

- Joined

- Sep 25, 2015

- Messages

- 44

- Reaction score

- 12

On the FB site people mentioned the idea of needing to secure the hop cages using the rubber gaskets so they don't open. Has anyone had this issue? Not me - and I have never used them...

The lids on my hop cages fit fairly snugly. I can't imagine they would ever come off or need any extra gasket to hold them in place. I wonder if that's on the early release units.

Also, I'm just going to throw this out there even though it has nothing to do with the current topic. On the Picobrew site forum there is a long thread about efficiencies. I wonder if it has less to do with grain crush and more to do with ph and water amendments? I've hit or exceeded my O.G. Every time so far whether it be single infusion or step mash. I start off with RO water and adjust ph (in the brewing keg) and add calcium sulfate and calcium chloride directly to the grains.

Baja_Brewer

Well-Known Member

On the FB site people mentioned the idea of needing to secure the hop cages using the rubber gaskets so they don't open. Has anyone had this issue? Not me - and I have never used them...

Wonder if there has been a design change since the pre-order Z's- mine press fit in place with no concerns about them coming off - I can even pick one up full of wet hops by the lid without it separating from the base.

BentBrewer

Well-Known Member

Thanks for the clarification. This helps quite a bit!

The issue I ran into was that the Pico cleaning tabs worked okay -- but when I used PBW it did, indeed, strip all the gunk out of the machine that the cleaning tabs failed to remove.

So is the takeaway here that PBW is a last resort? Only if you have -- or think you have -- pump/water flow issues?

Has this issue been addressed yet other than don't use it? Obviously it works far better than the tabs provided. It's either clean or it is not.

.

Are there any internal parts of plastic etc that can be damaged or just the filter? If it is just the step filter then I wonder what it would take to make this out of stainless?

Current knowledge seems to be to run a citric acid cleaning cycle after doing the cleaning tab cycle. The citric acid does seem to knock a lot more stuff loose from the machine.

Stolen from the Facetube group:

It's 2 tbsp. citric acid in the filter for a clean cycle AFTER the regular clean cycle.

My hop cage lids are tight also (10 brews so far). I suspect the issue is that the fit gets sloppier after extended use. I plan to keep an eye on that and start using the bands if an issue arises.

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

I have only a couple of 2.5 gallon kegs in my rotation. They work well for 2.5 gallon batches. Saves CO2, for one thing. I'll be picking up some more.

Baja_Brewer

Well-Known Member

I'd say the same thing. No need for more headspace than you have beer, first of all. Otherwise you're just using a ton of CO2 to purge the keg (you are purging, aren't you?!) I picked up/rebuilt 10 3-gallon pinlocks and converted them to ball-lock. I still don't have the fully sorted out (its on the to do list for tomorrow, actually) but its nice to have smaller kegs for secondary/aging/serving.

Baja_Brewer

Well-Known Member

Wow! Did you go pick yours up at the PicoBrew facility?! Are those the Zymatics or the Picos?

Wow! Did you go pick yours up at the PicoBrew facility?! Are those the Zymatics or the Picos?

I picked mine up. Awesome place. Crazy number of people work there and that has nothing to do with manufacturing. Incredibly nice and accommodating people.

That is a lovely wall of zymatics ready to go out. There were a few demo-like pico's sitting around, but they are not ready to ship any picos for a month or so if I recall.

Baja_Brewer

Well-Known Member

Awesome!

Ok, so some boring news. Today I cleaned 4x3 gallon kegs that I have had sitting - 3 for at least a month since I bottled, and 1 that kicked sometime in the fall. The Scrubmaster made quick work of them - then the real effort began.

I purchased 4 of these 3 gallon pin-locks when I got back into brewing, specifically to accommodate the Zymatic batch sizes. They were ~$40 each and then I had to convert them to Ball Lock. Then I got another 6 when AIH were selling "loose handle kegs" - this time, they were $30/each, still requiring the conversions. For the first round of kegs, I had purchased the 19/32" posts that AIH sells for $10 based on their advice. They kinda worked. When I got the follow on kegs, I purchased 6 sets of the same posts, but ended up exchanging 3 sets for 9/16" posts - still couldn't get all of my kegs to cooperate (hold pressure, not leak, etc) but they were mixed and matched an I was frustrated so I kind of let it go. Some are Cornelius, some are Firestone, some unlabeled...

So today when I had 8 out of the 10 kegs clean (4 without fittings), and knew that some 2 out of 3 I knew were fitted with the 9/16", I decided to figure it out. I went through a process of elimination to figure out which of the 1 out of the 3 didn't have 9/16", then fitted the other kegs.

Those of you who are smarter than me probably know this already: Firestone are 9/16"-18, Cornelius are 19/32"-18. Unlabeled kegs? Well the Firestone style have a dip-tube that is straight down, and the Corny style have the curved dip-tube - this yields bottoms that look different!

Left (Firestone), Right (Cornelius)

Mystery solved, just need to order 3 more 9/16" fittings. And I have enough clean kegs on hand to keg my Belgian Dubbel, Grapefruit IPA, and APA!

Next - late in the season but I need a stout in my life - so I decided to hit the LHBS. To be completely honest, I'm not very good at supporting my LHBS - I'm cheap and prefer to buy bulk base malts and hops, plus its a half an hour away from home in the wrong direction from work and frankly, the owner is a bit of a douchenozzle.

Anyway, I'm making this: https://www.homebrewtalk.com/showthread.php?t=100740 since I can pull some Nottingham from underneath the APA I made last weekend, so I picked up some Malted Barley and Roasted Barley and EKG hops.

I did take advantage of my trip up there to get a deal on yeast - my favorite thing about this shop is that they mark the expired yeast down to $1-2/vial for White Labs. Everywhere else I know only cut the price in half. Last time I was there I got 2xWLP 545 (Belgian Strong Ale) and 2xWLP 570 for $2/each, some over a year old, and I was able to do stepped up starters and get them working great.

So this time, at $1/ea, I grabbed:

Oldest one expired in March last year, but the rest are 7 months or less out - so I should be in good shape!

All in all, I left there very happy. Planning on brewing tomorrow when we're hunkered down in the cold!

Ok, so some boring news. Today I cleaned 4x3 gallon kegs that I have had sitting - 3 for at least a month since I bottled, and 1 that kicked sometime in the fall. The Scrubmaster made quick work of them - then the real effort began.

I purchased 4 of these 3 gallon pin-locks when I got back into brewing, specifically to accommodate the Zymatic batch sizes. They were ~$40 each and then I had to convert them to Ball Lock. Then I got another 6 when AIH were selling "loose handle kegs" - this time, they were $30/each, still requiring the conversions. For the first round of kegs, I had purchased the 19/32" posts that AIH sells for $10 based on their advice. They kinda worked. When I got the follow on kegs, I purchased 6 sets of the same posts, but ended up exchanging 3 sets for 9/16" posts - still couldn't get all of my kegs to cooperate (hold pressure, not leak, etc) but they were mixed and matched an I was frustrated so I kind of let it go. Some are Cornelius, some are Firestone, some unlabeled...

So today when I had 8 out of the 10 kegs clean (4 without fittings), and knew that some 2 out of 3 I knew were fitted with the 9/16", I decided to figure it out. I went through a process of elimination to figure out which of the 1 out of the 3 didn't have 9/16", then fitted the other kegs.

Those of you who are smarter than me probably know this already: Firestone are 9/16"-18, Cornelius are 19/32"-18. Unlabeled kegs? Well the Firestone style have a dip-tube that is straight down, and the Corny style have the curved dip-tube - this yields bottoms that look different!

Left (Firestone), Right (Cornelius)

Mystery solved, just need to order 3 more 9/16" fittings. And I have enough clean kegs on hand to keg my Belgian Dubbel, Grapefruit IPA, and APA!

Next - late in the season but I need a stout in my life - so I decided to hit the LHBS. To be completely honest, I'm not very good at supporting my LHBS - I'm cheap and prefer to buy bulk base malts and hops, plus its a half an hour away from home in the wrong direction from work and frankly, the owner is a bit of a douchenozzle.

Anyway, I'm making this: https://www.homebrewtalk.com/showthread.php?t=100740 since I can pull some Nottingham from underneath the APA I made last weekend, so I picked up some Malted Barley and Roasted Barley and EKG hops.

I did take advantage of my trip up there to get a deal on yeast - my favorite thing about this shop is that they mark the expired yeast down to $1-2/vial for White Labs. Everywhere else I know only cut the price in half. Last time I was there I got 2xWLP 545 (Belgian Strong Ale) and 2xWLP 570 for $2/each, some over a year old, and I was able to do stepped up starters and get them working great.

So this time, at $1/ea, I grabbed:

- 2x WLP 570 Golden Strong Ale (again, since I wasn't able to recover as much as I wanted)

- 3X WLP 530 Abbey Ale Yeast

- 2x WLP 500 Monestary Ale Yeast

- 1x WLP 013 London Ale Yeast

Oldest one expired in March last year, but the rest are 7 months or less out - so I should be in good shape!

All in all, I left there very happy. Planning on brewing tomorrow when we're hunkered down in the cold!

Baja_Brewer

Well-Known Member

Baja_Brewer

Well-Known Member

Batch finished up just fine. No leaks, greasing the plugs worked great again. Took about five hours from start to finish chilling with a 90 minute single step infusion mash. Used 4.2 gallons of water (35lbs) for an intended final volume of 3 gallons. Pitched Nottingham that I recovered doing a closed vessel transfer of my APA from last Sunday- I hope it was enough, but fermentation started within an hour!

Actually a quick not about that- they recommend cutting the dip tubes of your 5 gallon cornies by about 1/2", I did that to 3 of my six kegs... If you plan on doing closed vessel transfers and harvesting yeast like I have been (because at $4/ pack for dry yeast on 3-gallon batches, why wouldn't you?) I would either keep the full length or maybe only take off 1/4" so that it ends up in the yeast cake/trub.

Anyway, pics for clicks- current fermentation- we're going to be gone for the weekend so the house will be a nice 63°F for fermentation.

Actually a quick not about that- they recommend cutting the dip tubes of your 5 gallon cornies by about 1/2", I did that to 3 of my six kegs... If you plan on doing closed vessel transfers and harvesting yeast like I have been (because at $4/ pack for dry yeast on 3-gallon batches, why wouldn't you?) I would either keep the full length or maybe only take off 1/4" so that it ends up in the yeast cake/trub.

Anyway, pics for clicks- current fermentation- we're going to be gone for the weekend so the house will be a nice 63°F for fermentation.

Baja_Brewer

Well-Known Member

Wouldn't let me upload at first...

Also, that APA batch filled my 3 gallon keg just fine with a starting volume of 4.2 gallons.

View attachment 1455806482410.jpg

Also, that APA batch filled my 3 gallon keg just fine with a starting volume of 4.2 gallons.

View attachment 1455806482410.jpg

When you dry hop using the corny kegs for fermentation do you use bags or just drop em in? Just wondering if they settle enough for pressure transfer. Btw what pressure do you transfer at? Thanks!!

Baja_Brewer

Well-Known Member

Bags. I picked up 5 mesh bags off of Amazon. I'll double bag when I do hot, late hop additions (I've found if I only use one the inline hop filter gets clogged) and dry hops. I'll pull the bag before I transfer.

I've been transferring at 5-10 psi depending on how much of a hurry I'm in. When I did three transfers the other day I did about 10 psi. Purge the large keg, purge the receiving keg twice, grab the trub (first runnings, kind of) from the large keg using the picobrew keg wands into a sanitized ball jar, complete the transfer into the small keg while bleeding off pressure out of the gas port.

I've been transferring at 5-10 psi depending on how much of a hurry I'm in. When I did three transfers the other day I did about 10 psi. Purge the large keg, purge the receiving keg twice, grab the trub (first runnings, kind of) from the large keg using the picobrew keg wands into a sanitized ball jar, complete the transfer into the small keg while bleeding off pressure out of the gas port.

hey Baja i also had a few hiccups with my step filter, first where the plug, now was the drain gasket came out, but anyway pico shipped a replacement to me after they localized the problem..! last 3 brews were all messy because of all this stuff that happened..! but beer came out ok.. less volume but nice.!

Baja_Brewer

Well-Known Member

hey Baja i also had a few hiccups with my step filter, first where the plug, now was the drain gasket came out, but anyway pico shipped a replacement to me after they localized the problem..! last 3 brews were all messy because of all this stuff that happened..! but beer came out ok.. less volume but nice.!

I figured others were in the same boat - sounds like yours was a bit harder to track down than mine. I'm glad that using the o-ring grease helped with my issue, because I certainly wasn't looking any deeper like you were!

Tonight I made a starter. Well, two starters, actually. I want to get the WLP 530 (Abbey Ale yeast) vials that I purchased for $1/ea up and running. I was going to combine the in one big starter, but got to thinking while re-reading the Pitch It, Don't Toss It blog post recommending a 500mL starter for starter for 1 vial, that if I used 2 separate starters I could also use 1qt mason jars, and observe the first step.

No pictures yet, but I used 60g of Pilsen DME in 1 qt of water, and now have a vial that expired 3/2015 and one that expired 8/2015 sitting in weak wort on my counter.

Ultimately, I plan on combining the two. This weekend I plan on brewing back to back batches of Revvy's Leffe Blone Clone, and pitching the WLP 530 in one, and Safbrew Abbaye Yeast in the other. My first true experiment with the Zymatic! The only hangup I will have is that I can only monitor the temp of one at a time in my ferm chamber, so I'm thinking I might just let them free-ride at ambient (65-68*F) in my living room, rather than having one control the temp of the other in the fermentation chamber. This way they'll age at the same rate, etc.

I'm pretty excited! Will post notes on the starters as they progress.

In other news, I ordered the ball-lock posts for my remaining 3x3 gallon kegs, and the ingredients I need for about 10 more brews. I need to build some other yeast starters after these finish, and work on the bottles of Ommegang in my fridge to harvest that yeast :rockin:

Baja_Brewer

Well-Known Member

One of the starters has started as of this evening (~48 hours in)- albiet slowly. Not surprisingly, its the one that expired in 8/15 rather than the one from 3/15. While I've done my best to ensure proper sanitization, I'm concerned that the one that hasn't started yet may become infected - the starter wort is certainly starting to smell sour. Anyone reading this with a good bit of yeast ranching/revival experience? Am I risking infection? Thinking I'll hold off on combining the two.

Based on the slow response I've had, and the fact that I have a good number of other yeasts that I want to try and bring back to life - I decided it was time to pull the trigger on a stir plate. Despite owning the Picobrew - I really am a big DIY kinda guy - but in this case I wanted the cheapest AND quickest option for a stir plate - no wiring, etc. I hit Google real quick, and this was the second thread I turned up for an easy, cheap DIY Stirplate. I have fender washers in the garage, a few rare earth magnets, and the "stir plate" was so cheap that I even decided to spring for a flask to go with the 1.5" stir bar. Total cost? $33.01. I bet I can have it up and running within a few hours of the Amazon order arriving on Friday, and I will step the starter for a Sunday brew day - probably going to do another 1.020 starter tomorrow to keep the 8/15 yeast active.

Based on the slow response I've had, and the fact that I have a good number of other yeasts that I want to try and bring back to life - I decided it was time to pull the trigger on a stir plate. Despite owning the Picobrew - I really am a big DIY kinda guy - but in this case I wanted the cheapest AND quickest option for a stir plate - no wiring, etc. I hit Google real quick, and this was the second thread I turned up for an easy, cheap DIY Stirplate. I have fender washers in the garage, a few rare earth magnets, and the "stir plate" was so cheap that I even decided to spring for a flask to go with the 1.5" stir bar. Total cost? $33.01. I bet I can have it up and running within a few hours of the Amazon order arriving on Friday, and I will step the starter for a Sunday brew day - probably going to do another 1.020 starter tomorrow to keep the 8/15 yeast active.

KirkMN

Well-Known Member

I like using a stir plate for starters. It's always great to know the yeast is happy prior to pitching in the large volume. I had all of the parts to make one, but ended up just buying one for $40 and it came with the magnets. Remember to get a small magnet to use on the outside of your flask to hold the stir bar in place so you don't pitch it with the yeast.

Baja_Brewer

Well-Known Member

I like using a stir plate for starters. It's always great to know the yeast is happy prior to pitching in the large volume. I had all of the parts to make one, but ended up just buying one for $40 and it came with the magnets. Remember to get a small magnet to use on the outside of your flask to hold the stir bar in place so you don't pitch it with the yeast.

Ahhh, good point - sounds a mistake I would make once or twice! The magnets I have are really strong, so I think I will only need 2 for the stir plate - should have some spares for stir bar retention.

As for buying one, I looked at one for $35 on Amazon - but the recent reviews were terrible - and since the fan I ordered has the speed controller integrated, I figure slapping a washer with some magnets on there would be easy. Hopefully it still has the fan guards that allow it to just lay down for now - I'll come up with a better enclosure later.

Edit: So I just went back and looked at my other newly aquired expired yeast vials - the Abbey Ale from 3/15 that isn't started is the oldest one - next most recent ones expired in June - going to get those fired up in the next week or so.

Baja_Brewer

Well-Known Member

Spent about 45 minutes making this last night. Didn't have super glue so I used hot glue. Will touch it up later. Magnets are loose so I can adjust them as needed. They're really strong so I had to trim the fan guard back further than I thought I would have to initially.

Right now I have a size issue- the magnets stick up further than the fan guard. Not an issue for mason jars because the bottom is rounded up. Also not an issue for the flask because it sets on top of the screws , but its going to motivate me to put this in an enclosure.

The different speeds are cool, I can get a full vortex or a mild one.

View attachment 1456574778545.jpg

View attachment 1456574790312.jpg

View attachment 1456574800082.jpg

Right now I have a size issue- the magnets stick up further than the fan guard. Not an issue for mason jars because the bottom is rounded up. Also not an issue for the flask because it sets on top of the screws , but its going to motivate me to put this in an enclosure.

The different speeds are cool, I can get a full vortex or a mild one.

View attachment 1456574778545.jpg

View attachment 1456574790312.jpg

View attachment 1456574800082.jpg

Baja_Brewer

Well-Known Member

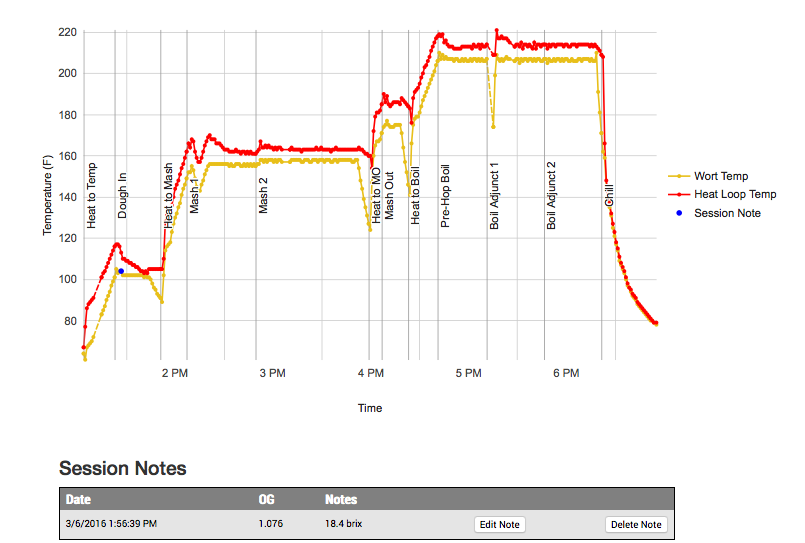

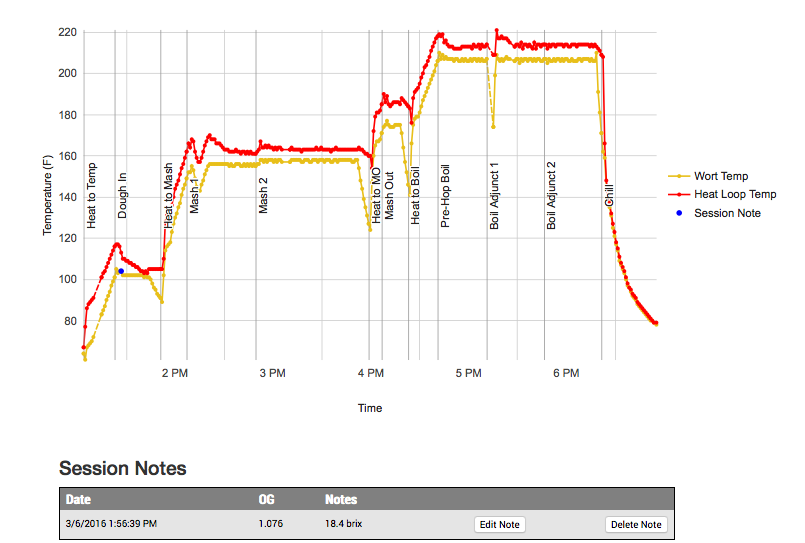

I got around to doing the double brew day on Sunday. It took almost 12 hours start to finish, having measured out the grains the night before. There were a few issues:

I debated not correcting the mash temp for the second brew, but I wanted to follow Revvy's recipe, so I did correct it. I don't anticipate any issues with having added the boiled sugar water after the first one was chilled. I wish I knew the OG of the first one, but I'm going to guess that they're the same or close. Everytime I do a multistep mash I seem to come in under volume (I'm guessing) and over gravity - so I'm wondering if Picobrew's calcs might be off or... I don't know, my crush is different than expected so it holds more water? I think my crush is right in the middle of their range.

I pitched the WLP530 in the first one and the Abbeye Ale yeast in the second - both are probably overpitched. Both of the beers are fermenting away right now at room temp (~66*F)

So I'd call my first experiment with this a pretty lousy experiment. We'll see how they turn out! Probably going to primary ferment for two weeks, transfer to 3 gallon kegs and secondary for at least a month, and then bottle - depending on my need for the 3 gallon kegs ( 5 have beer in them right now, 1 of those is aging and another is probably a dumper)

- I modified the recipe the night before, which wiped out my advanced editor mash temps of 158*F. Picobrew REALLY needs to fix this issue.

- I forgot to add the boiled sugar water to the first brew, and did so after the brew was chilled

- I forgot to take the OG on the first brew

I debated not correcting the mash temp for the second brew, but I wanted to follow Revvy's recipe, so I did correct it. I don't anticipate any issues with having added the boiled sugar water after the first one was chilled. I wish I knew the OG of the first one, but I'm going to guess that they're the same or close. Everytime I do a multistep mash I seem to come in under volume (I'm guessing) and over gravity - so I'm wondering if Picobrew's calcs might be off or... I don't know, my crush is different than expected so it holds more water? I think my crush is right in the middle of their range.

I pitched the WLP530 in the first one and the Abbeye Ale yeast in the second - both are probably overpitched. Both of the beers are fermenting away right now at room temp (~66*F)

So I'd call my first experiment with this a pretty lousy experiment. We'll see how they turn out! Probably going to primary ferment for two weeks, transfer to 3 gallon kegs and secondary for at least a month, and then bottle - depending on my need for the 3 gallon kegs ( 5 have beer in them right now, 1 of those is aging and another is probably a dumper)

Baja_Brewer

Well-Known Member

Also - I now, finally, have a way to serve beer from my fridge (that I can't drill.) A pour of my stout this evening, for starters:

The Guinness souring method worked great. It is a little roastier on the back end then I would like- but I bet that will mellow with time... if it lasts that long!

So here is how my fridge is currently set up:

And a potato quality image showing the tap coming off of the keg a bit better - since its on a ball-lock connection I can swivel it away to keep it away from the door, and then back out to serve.

I'm currently pouring at 15 psi and it came out great - I'll have to try my APA in the next could days to see if I can show how the carb levls come out. The set up was a bit spendy (the 650SS isn't cheap, and then its another $35 shipped for the Chi-company 1/4" to Perlick adapter - I think they're the only one that has them) but given that this will allow me to take a keg on the go without picnic lines or anything, I think it will pay off in the long run!

The Guinness souring method worked great. It is a little roastier on the back end then I would like- but I bet that will mellow with time... if it lasts that long!

So here is how my fridge is currently set up:

And a potato quality image showing the tap coming off of the keg a bit better - since its on a ball-lock connection I can swivel it away to keep it away from the door, and then back out to serve.

I'm currently pouring at 15 psi and it came out great - I'll have to try my APA in the next could days to see if I can show how the carb levls come out. The set up was a bit spendy (the 650SS isn't cheap, and then its another $35 shipped for the Chi-company 1/4" to Perlick adapter - I think they're the only one that has them) but given that this will allow me to take a keg on the go without picnic lines or anything, I think it will pay off in the long run!

Baja_Brewer

Well-Known Member

Grrrrr..... one of the lids doesn't seat well and it drained my NEW replaced CO2 tank. $23 to refill, here I go. #HomebrewProblems

So either I way over pitched the WLP530 yeast, or its infected - the keg with the blue top in the potato phone picture - you can't really tell but the airlock is all cloudy with yeast buildup:

And it actually blew off for a while - this is the yeast run-off down the side and build up on the base. 3 days in and the kegs are both still bubbling. I moved them to the basement stairs to to help drop the temp for a while, but now that they've slowed down I have them back in the living area (~67*F.)

So even though I'm only running two kegs, I feel the need to brew something to have on tap soon (running a stout and APA, have an IPA I'll probably rotate in, and a Ginger IPA from forever ago I'll see if is still good) - so I might brew if I take the day off on Friday (got the ***-its real bad this week.) Thinking I might take another swing at a grapefruit IPA using the NB recipe, but wondering if I should try and improve my first attempt with a grapefruit peel soaked in vodka approach - that seems to be key. I've had poor luck with IPAs in the Pico - hoping to nail one down real soon.

I also have a few more starters to build before those yeasts expire. Want to get my current stir plate into the enclosure I have, and I'm considering building another with different magnets.

Sorry this thread has turned into a general stream of consciousness. I'm a little frustrated with Picobrew right now - the software is still a little clunky (see my note about the mash temps in the advance editor above) and we continue to get a bunch of hand waving "soon" and "in the next couple months" responses. Meanwhile they've launched their Kegsmarts system and are prepping their Pico launch... They're keeping the Pico and Zymatic forums separate and while they say that its because they're testing different forum platforms, but the skeptic/critic in me makes me wonder if they're trying to keep any discontent with the .... distance(?), between Zymatic upgrades from causing cancelled Pico orders. I would say lack of support, but they're very supportive - just not necessarily advancing the system to its full potential while continuing to shut out requests from others for open sourcing. While I haven't seen any obtuse outward discontent (admittedly I haven't looked - but I think resounding negative reviews would have caught my attention) there is a certain about of grumbling on the Zymatic forums.

Edit: I have caught wind that that a new version of the Zymatic firmware is in Beta testing - so there is hope there.... but it's been about a year.

So either I way over pitched the WLP530 yeast, or its infected - the keg with the blue top in the potato phone picture - you can't really tell but the airlock is all cloudy with yeast buildup:

And it actually blew off for a while - this is the yeast run-off down the side and build up on the base. 3 days in and the kegs are both still bubbling. I moved them to the basement stairs to to help drop the temp for a while, but now that they've slowed down I have them back in the living area (~67*F.)

So even though I'm only running two kegs, I feel the need to brew something to have on tap soon (running a stout and APA, have an IPA I'll probably rotate in, and a Ginger IPA from forever ago I'll see if is still good) - so I might brew if I take the day off on Friday (got the ***-its real bad this week.) Thinking I might take another swing at a grapefruit IPA using the NB recipe, but wondering if I should try and improve my first attempt with a grapefruit peel soaked in vodka approach - that seems to be key. I've had poor luck with IPAs in the Pico - hoping to nail one down real soon.

I also have a few more starters to build before those yeasts expire. Want to get my current stir plate into the enclosure I have, and I'm considering building another with different magnets.

Sorry this thread has turned into a general stream of consciousness. I'm a little frustrated with Picobrew right now - the software is still a little clunky (see my note about the mash temps in the advance editor above) and we continue to get a bunch of hand waving "soon" and "in the next couple months" responses. Meanwhile they've launched their Kegsmarts system and are prepping their Pico launch... They're keeping the Pico and Zymatic forums separate and while they say that its because they're testing different forum platforms, but the skeptic/critic in me makes me wonder if they're trying to keep any discontent with the .... distance(?), between Zymatic upgrades from causing cancelled Pico orders. I would say lack of support, but they're very supportive - just not necessarily advancing the system to its full potential while continuing to shut out requests from others for open sourcing. While I haven't seen any obtuse outward discontent (admittedly I haven't looked - but I think resounding negative reviews would have caught my attention) there is a certain about of grumbling on the Zymatic forums.

Edit: I have caught wind that that a new version of the Zymatic firmware is in Beta testing - so there is hope there.... but it's been about a year.

Baja_Brewer

Well-Known Member

Fired up the two vials of WLP500 this weekend - which is now call Monestary Ale yeast rather than Trappist Ale - they expired in June 2016, so I put them in a ~1l starter at 1.020. Also put some Ommegang dregs onto the same strength wort, so hopefully that will start building up some cells.

Aside from that I cleaned the Picobrew and straightened up the brewery this weekend... since I could finally have the garage doors open - wow it was nice out.

The Belgian Blonde that I pitched with WLP530 filled the airlock with yeast, again! The Safbrew Abbaye sulfur smell has receded significantly, but still smells. Apparently this is common: https://www.homebrewtalk.com/showthread.php?t=487645

Aside from that I cleaned the Picobrew and straightened up the brewery this weekend... since I could finally have the garage doors open - wow it was nice out.

The Belgian Blonde that I pitched with WLP530 filled the airlock with yeast, again! The Safbrew Abbaye sulfur smell has receded significantly, but still smells. Apparently this is common: https://www.homebrewtalk.com/showthread.php?t=487645

Baja_Brewer

Well-Known Member

Wow, its been about 3 months since I've posted. In that time I've managed 8 brews. 2 different Chimay Premier attempts, something that ended up being way too bitter, a grapefruit IPA, a Simcoe SMaSH and another Mosaic SMaSH, an attempt at an Art of Darkness clone (without Pilsner malt... so we'll see...) and I did a mash to finish off an extract Gose that I ran out of Extract for. These have all been fermented at room temperatures since my house is about 66-68 in the winter, and the most recent ones are being fermented in the basement which has come up to about the same temperature.

Picobrew has released 3 versions of firmware for the machine in the past few months- the first (1.1.10) had a bug that made the keg pump stay on when the machine was attempting to drain. Yours truly was the one to discover this lovely feature and let them know, but only after the mash tun flooded my hop additions pre-emtively (see the beer that was way too bitter.) Their response was to pull down the firmware and re-issue it as 1.1.11 the following week, which corrected that issue. Since then 1.1.12 has been released, I don't know what the changes were for this but I didn't have any issues that I was aware of when I brewed last weekend.

Editing recipes still wipes out and advanced recipe settings (i.e. temperature changes or specific hop basket selections if hop additions are being made directly in the brewing keg) - which continues to frustrate beyond all else. They're busy rolling out the Pico right now, so I doubt we'll be seeing any changes to this in the near future.

Hope to be brewing again later this week. Will try and scrape together a more interesting post soon.

Picobrew has released 3 versions of firmware for the machine in the past few months- the first (1.1.10) had a bug that made the keg pump stay on when the machine was attempting to drain. Yours truly was the one to discover this lovely feature and let them know, but only after the mash tun flooded my hop additions pre-emtively (see the beer that was way too bitter.) Their response was to pull down the firmware and re-issue it as 1.1.11 the following week, which corrected that issue. Since then 1.1.12 has been released, I don't know what the changes were for this but I didn't have any issues that I was aware of when I brewed last weekend.

Editing recipes still wipes out and advanced recipe settings (i.e. temperature changes or specific hop basket selections if hop additions are being made directly in the brewing keg) - which continues to frustrate beyond all else. They're busy rolling out the Pico right now, so I doubt we'll be seeing any changes to this in the near future.

Hope to be brewing again later this week. Will try and scrape together a more interesting post soon.

thanks for maintaining this thread!

for cleaning with PBW, has anyone tried connecting the rotating arm directly to the drain with silicon tubing or something? this would remove the step filter from this process and protect it.

for cleaning with PBW, has anyone tried connecting the rotating arm directly to the drain with silicon tubing or something? this would remove the step filter from this process and protect it.

Similar threads

- Replies

- 6

- Views

- 480

- Replies

- 5

- Views

- 753

- Replies

- 3

- Views

- 609

Latest posts

-

Spike Conical Heater fails again--second in 3 years--ideas?

- Latest: Indian_villager

-

-

-

-

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)