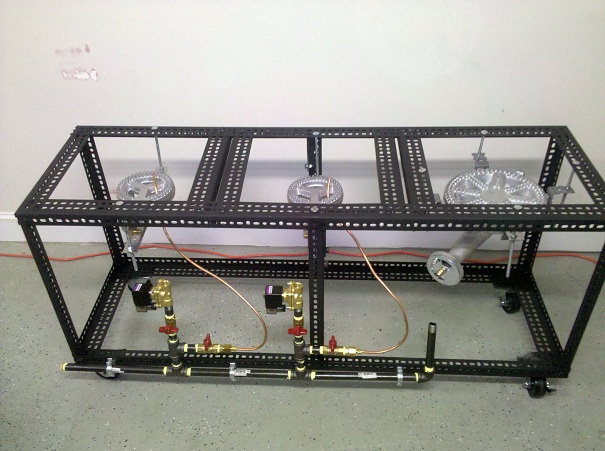

Okay, so Ive been brewing for about two years and finally decided to build a brew stand. I came up with a design that kind of combines pieces from other builds that Ive seen online. I dont possess the welding or metal working skills and farming the stand build out wouldnt fit in my budget, so I decided to use the Wallace stand seen here. I also combined some of the gas plumbing from other builds I have seen. As for the control panel, well, it will be a typical control panel with a master power switch, two Auber temp control switches, and toggles for the STC valves and March pumps.

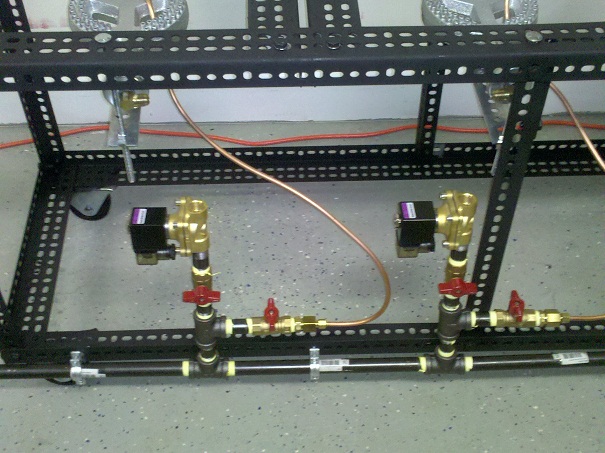

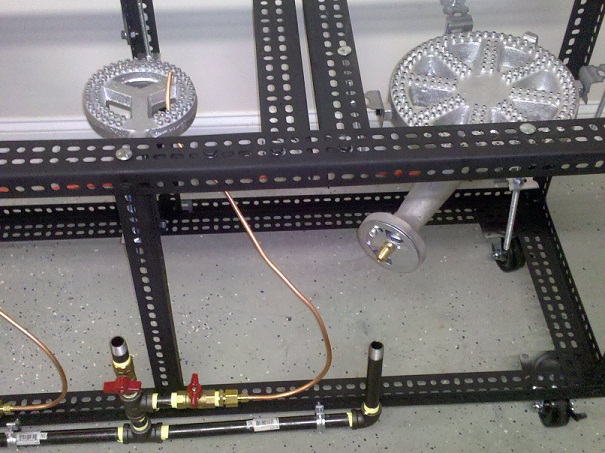

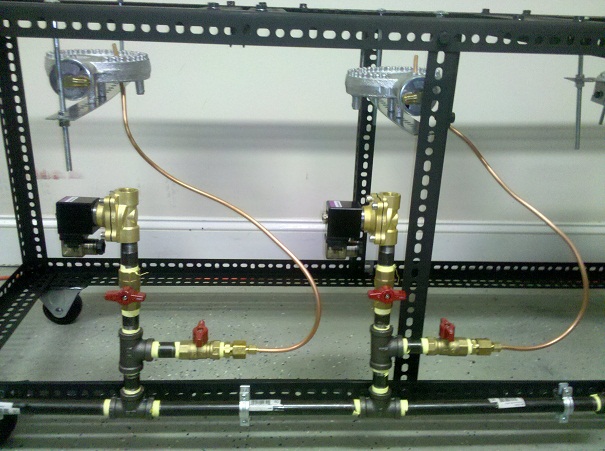

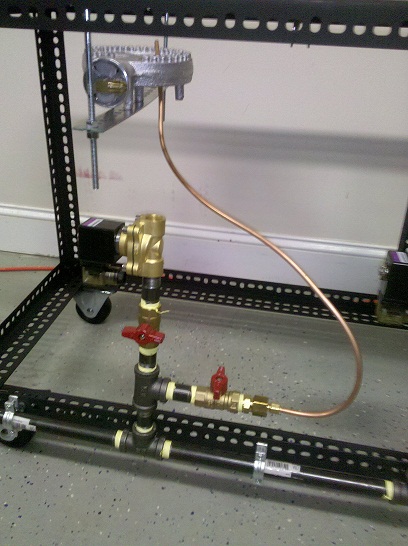

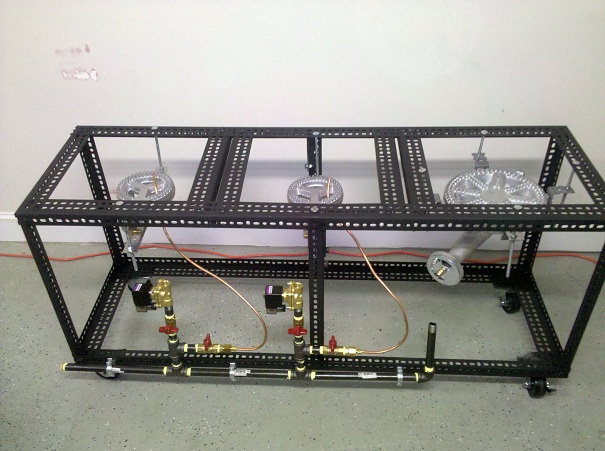

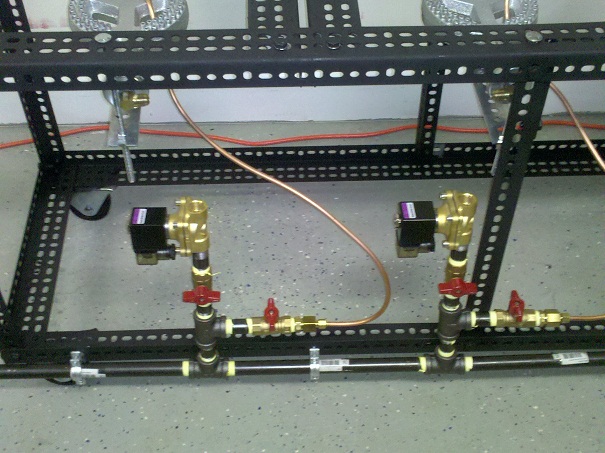

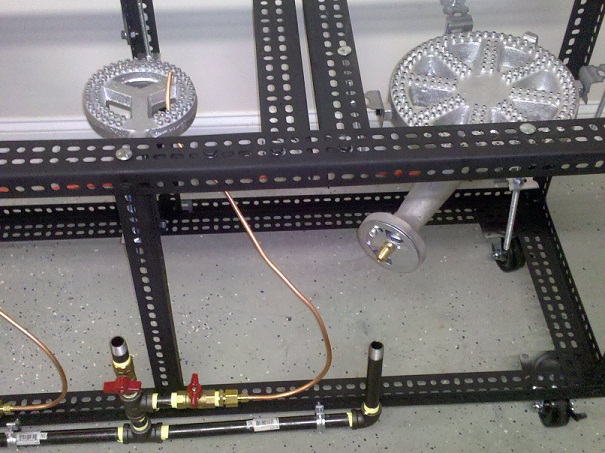

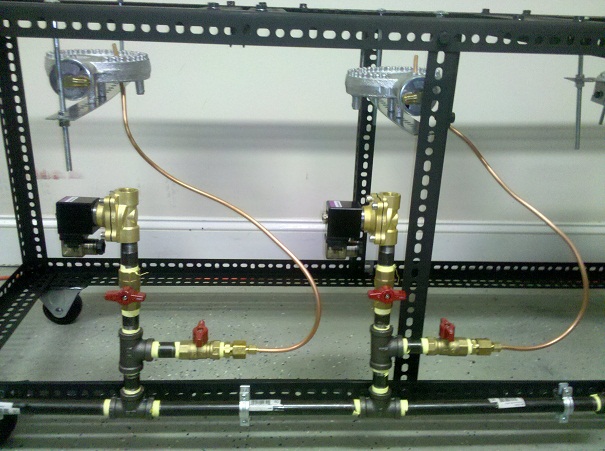

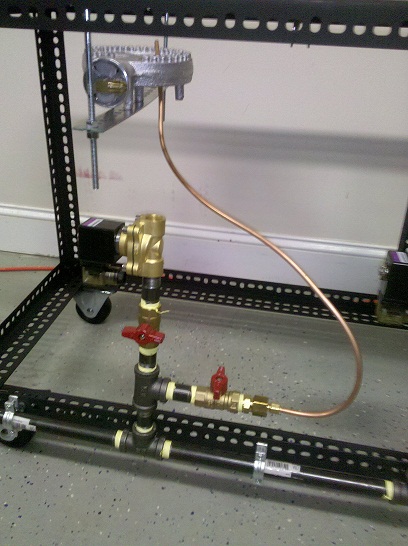

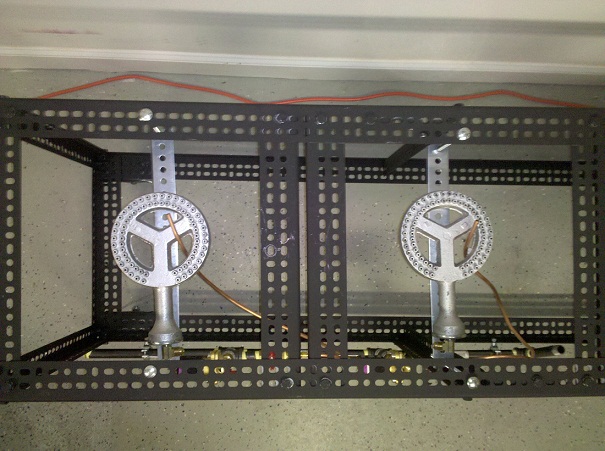

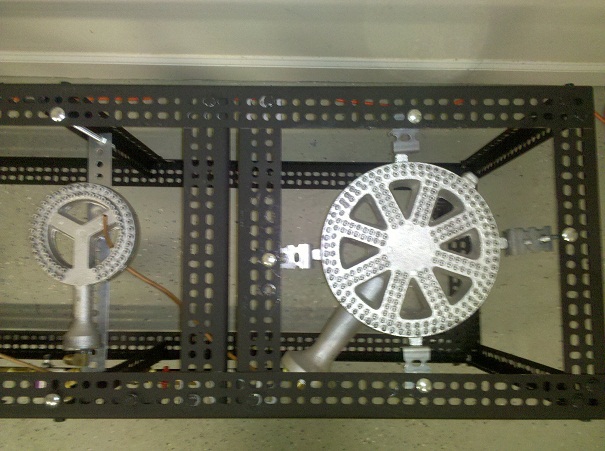

I might also mention that I have no previous experience working with gas or electrical panels so this build is turning out to be a huge learning experience for me. So far things have been moving right along. I have built the stand, mounted the burners (two 6 cast iron burners and one 10 banjo for the BK), built the main gas lines, and acquired three keggles (thanks to Sumit at LoneRider brewery). I still need to complete the gas connection to the main gas line and burners, build the control panel and outfit the keggles with another port or two and a hinged false bottom.

I think I need some help with the gas connections though. I would like to come from the tank to the main line at low pressure (the two 6 inch burners are low pressure) and then from the main line to the banjo using a high pressure regulator and adjuster (the banjo would be run manually). Not being a guru on gas Im not sure if this is correct thinking, or if so, are there other issues I havent considered? Also, even though Ive seen pilots setup like this on youtube and a couple of other build threads Im not sure if this pilot setup will work.

Anyway, here are some pics. I would appreciate any input or thoughts you guys may have.

I might also mention that I have no previous experience working with gas or electrical panels so this build is turning out to be a huge learning experience for me. So far things have been moving right along. I have built the stand, mounted the burners (two 6 cast iron burners and one 10 banjo for the BK), built the main gas lines, and acquired three keggles (thanks to Sumit at LoneRider brewery). I still need to complete the gas connection to the main gas line and burners, build the control panel and outfit the keggles with another port or two and a hinged false bottom.

I think I need some help with the gas connections though. I would like to come from the tank to the main line at low pressure (the two 6 inch burners are low pressure) and then from the main line to the banjo using a high pressure regulator and adjuster (the banjo would be run manually). Not being a guru on gas Im not sure if this is correct thinking, or if so, are there other issues I havent considered? Also, even though Ive seen pilots setup like this on youtube and a couple of other build threads Im not sure if this pilot setup will work.

Anyway, here are some pics. I would appreciate any input or thoughts you guys may have.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)