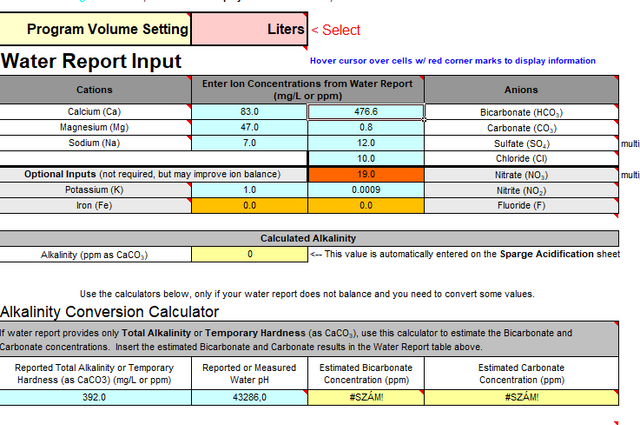

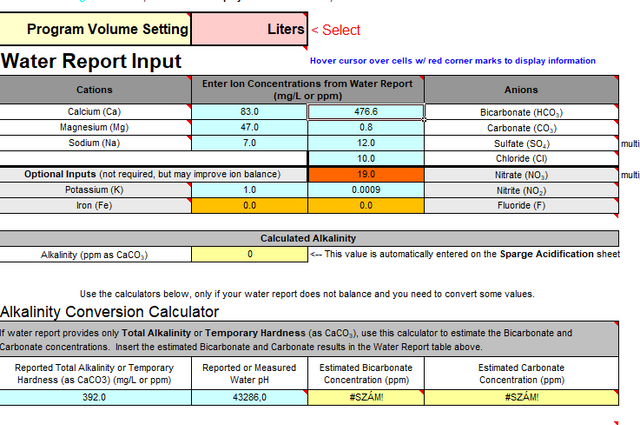

I changed the ',' to '.'. I think it necessary because some fields turned into orange in case of data where the comment said "enter zero if this value is not known". But i also have problem, because e.g. when i have to enter ph, it not accept 7.5 (it convert this into some kind of decimal number like: 43278,0 and i can not change the field format).

The bicarbonate: The Bru'n water says: 1 degree of german hardness equals to 17.85 CaCO3 in the introductions tab (i've found the similar info on the internet when i looked for calculators). So 22 degree of german hardness = 392CaCO3, i wrote this value into the reported alkalinity as CaCO3 field which counted me the bicarbonate i wrote into that field.

After changing ',' to '.':...

I've seen "errors" like that in Bru'n Water when a value is missing or wonky. It's usually caused by "solver" formulas that got out of hand, they need to get reset. Please fill in the correct values, using the decimal dot, on a

fresh copy of the program. That should give us a more useful overview.

By the way, I found

a source for the meaning of the "Nk" value, for those who were wondering:

Water hardness

The pleasure value of potable water and efficiency of the water used for washing are determined in part by the hardness of water, that is, its CaO (calcium oxide) mg/litre ratio. Water hardness figures indicate that in the region of the capital the water is mostly of medium hardness. It is important to know that the harder the water, the more pleasant flavourit has, but the lesser it is suitable for washing, and our washing machine does not like hard water. In most of the cases – e.g. on the labels of the detergents – water hardness is indicated in terms of the German standard of hardness (nk)*.

- Very soft water: under 40 CaO mg/litre (4 nk)

- Soft water: between 40-80 CaO mg/litre (4-8 nk)

- Medium-hard water: between 80-180 CaO mg/litre (8-18 nk)

- Hard water: between 180-300 CaO mg/litre (18-30 nk)

- Very hard water: above 300 CaO mg/litre (30 nk)

In the service area of our Company, the average hardness of potable water is 141 CaO mg/l.

*

The German standard for hardness (nk) is one tenth of the CaO mg/litre, so for 141 CaO mg/litre, for example, this value is 14.1 nk (2016).

Pass this information on to the Brew Science forum when posting your question there, together with screenshots of the

new Bru'n Water calculations.

The originators/builders of Bru'n Water are on the Brew Science forum, they can help you with any questions on the matter.

Remember, I mentioned the missing Anions from your water report? Well we found those, and they are indeed in the alkalinity. You have

fairly hard water which may not be all that suitable for brewing, as is, so some tweaking is definitely needed.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)