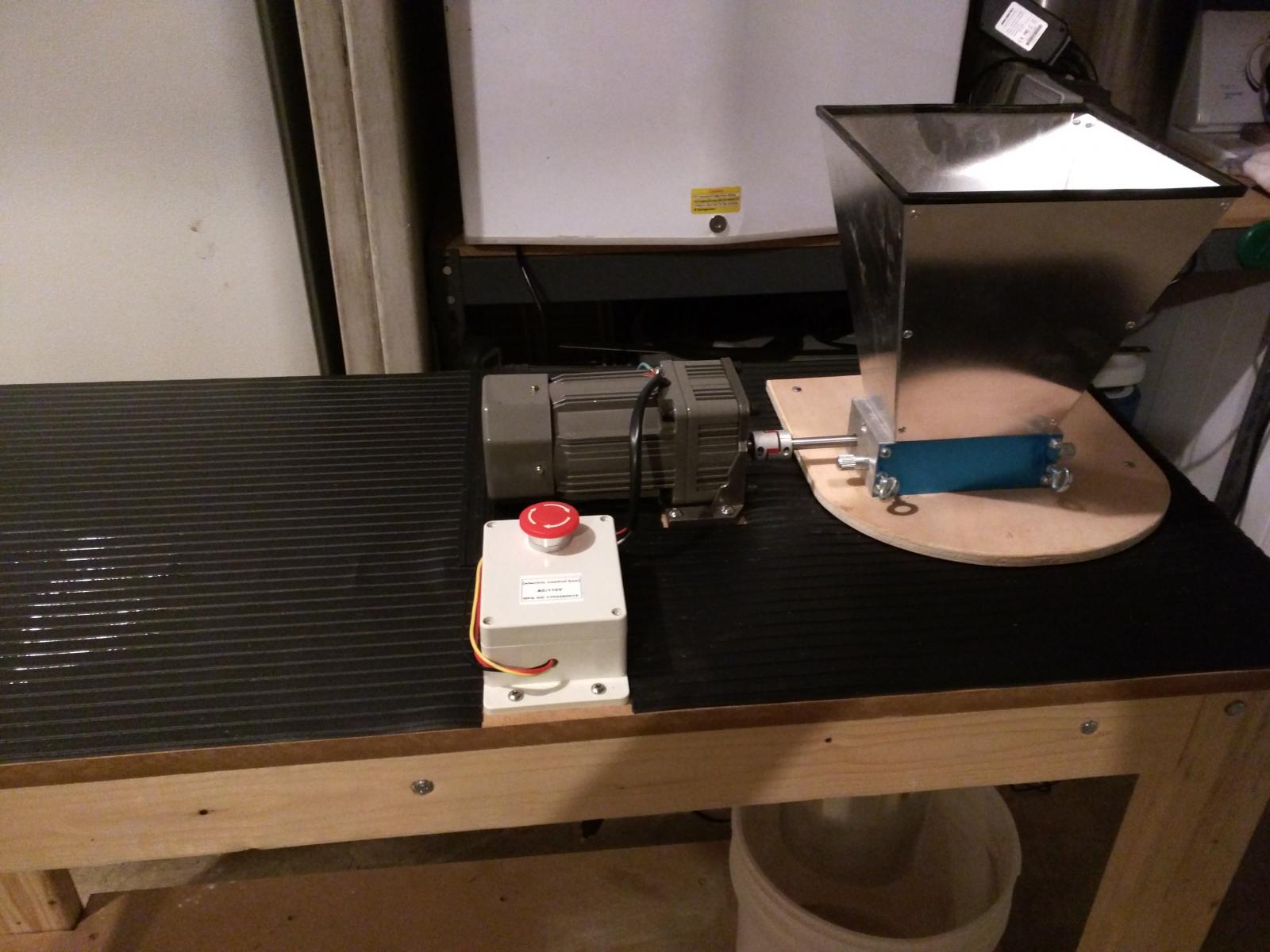

Finally finished the build. Crankandstein with an American ale works 180 rpm motor.

It's a beast! View attachment 392395View attachment 392396

Where did you get that hopper? Looks awesome! Very rural looking.

Nice build btw............

Finally finished the build. Crankandstein with an American ale works 180 rpm motor.

It's a beast! View attachment 392395View attachment 392396

Dcpcooks - that looks fantastic man. No issues with the motor weight on the stainless table, and is that 2x2 top? Also you pretty happy with the power grinder motor so far? Leaning towards that over the separate motor and reducer.

Cheers.

// brian

Thanks YesFan! The hopper is two pieces. The bottom half is the one from crankandstein. The top is a 5 gallon pale from the hardware store. I was going to build a hopper out of steel or aluminum but I kinda like this one as is. It holds a five gallon bucket full of grain so its fill once, mill then swap out the next bucket and repeat. It's roughly 17-20 lbs at once.

I really liked the MM3 hopper but I liked the self locking adjustable gap feature of the Crankandstein better.

Looks good man. I may go that route. The self adjusting locking gap.......... If I understand it, you don't need a feeler gauge as there are presets at every 0.05 increments?

How are you liking the Anvil scale? Does it have a dedicated on/off or does it auto shut off? I have an UltraShip scale. It's not bad, but I hate how it auto shuts off too soon. Was wondering if the Anvil is worth an upgrade.

Sorry for the off topic guys.

mine has been great. Highly recommend one to anyone looking to motorize with no old motors laying around.

Very Nice, love the cabinet.

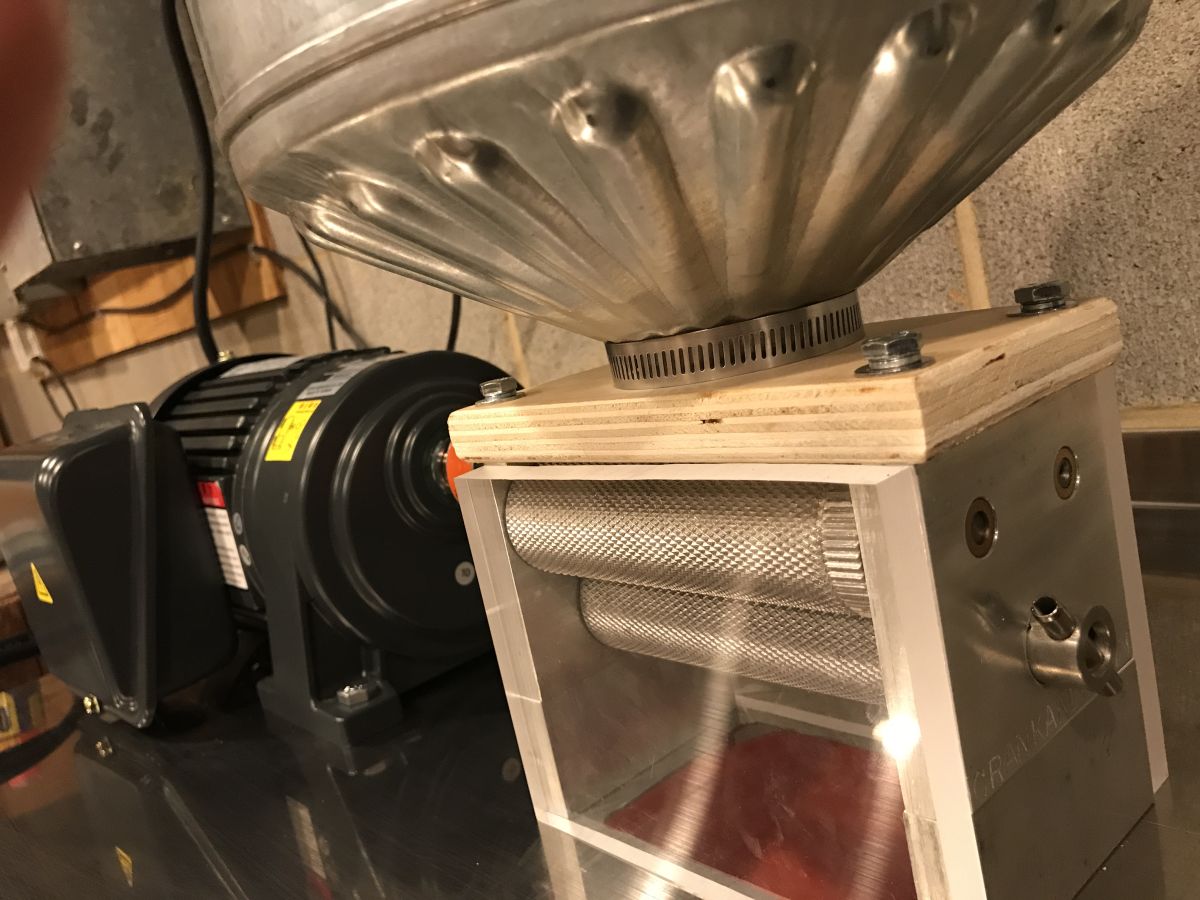

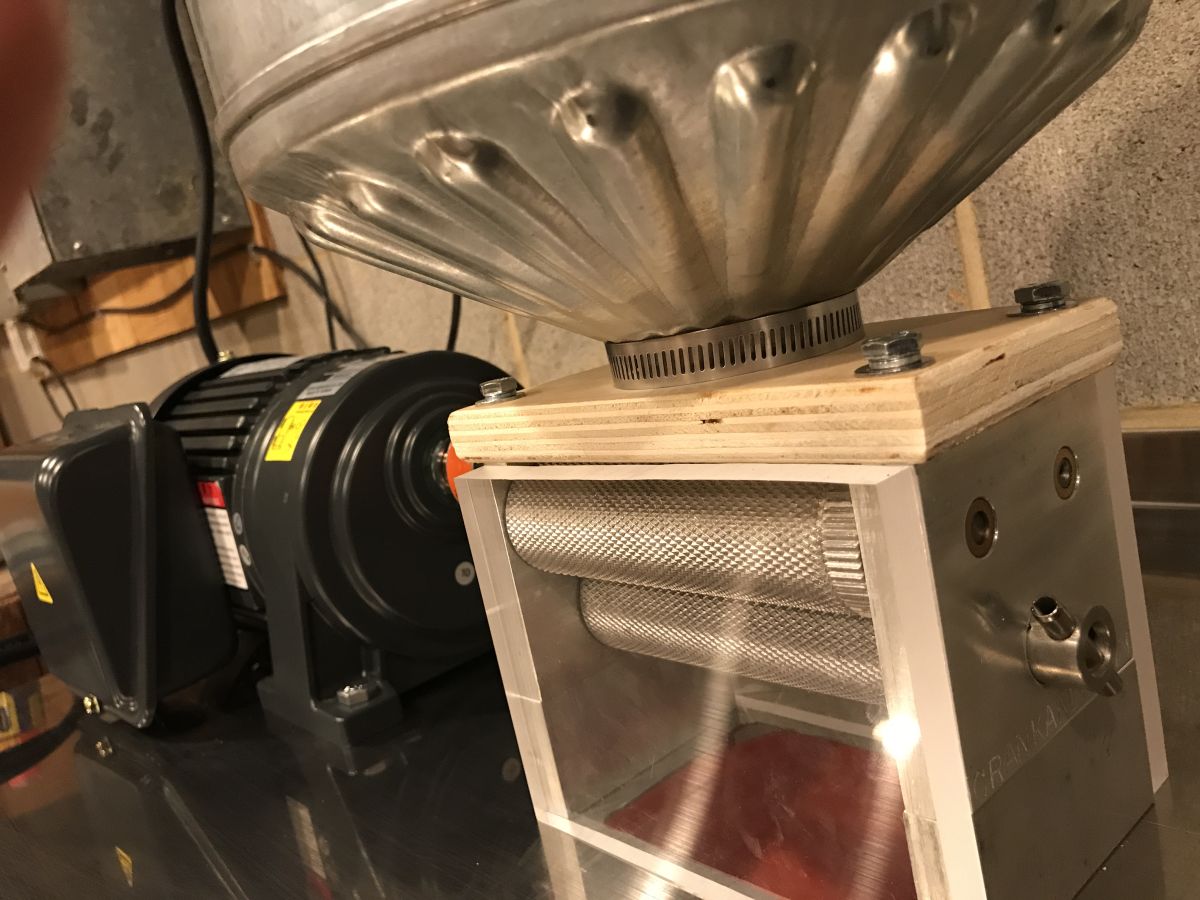

Just got done putting this together. All American Ale Works motor paired with a Monster Mill MM2 Pro.

I have the same set up. The MM2 Pro and the All American Ale Works motor. It is an awesome set up. I swear this thing would grind rock if you fill the hamper ith gravel. Nice crush. Just fill the hopper and flip the switch.

I have the same set up. The MM2 Pro and the All American Ale Works motor. It is an awesome set up. I swear this thing would grind rock if you fill the hamper ith gravel. Nice crush. Just fill the hopper and flip the switch.

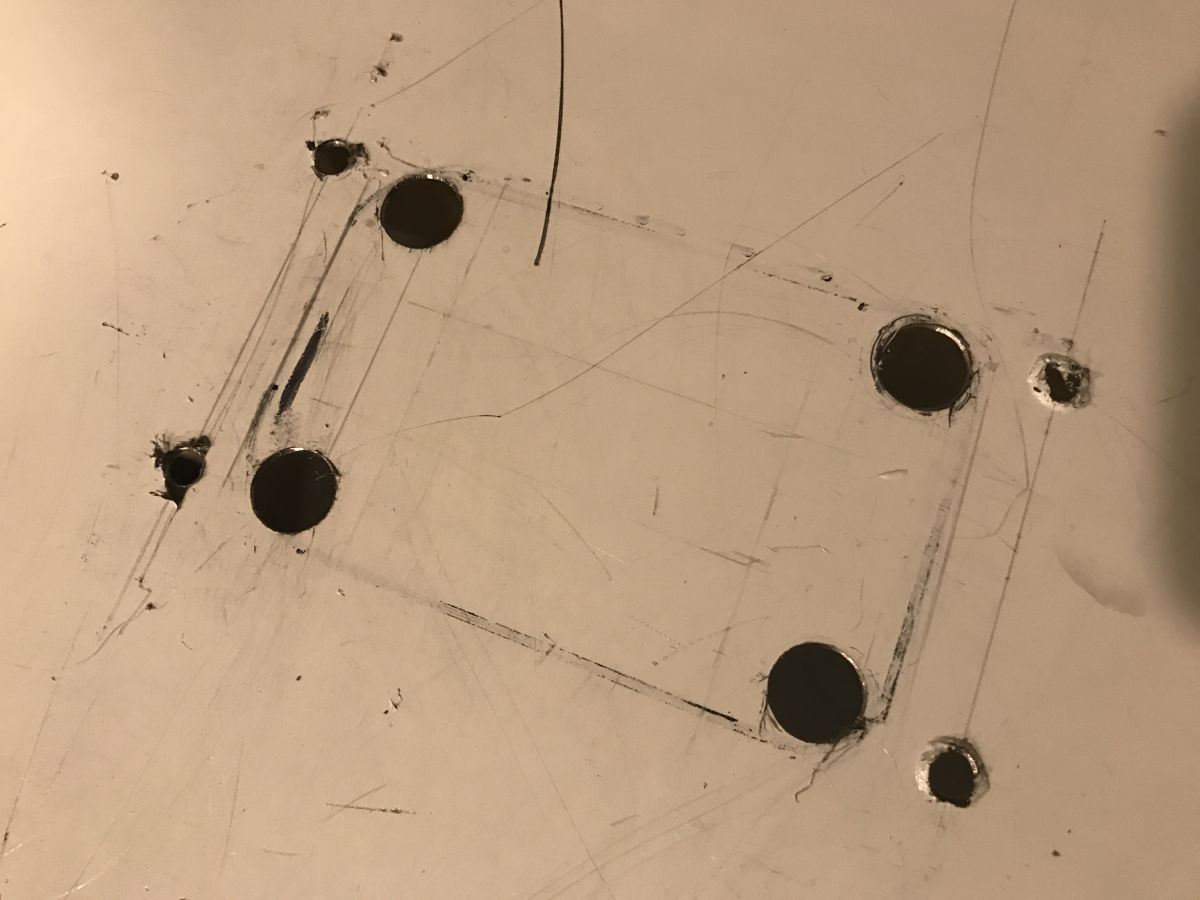

- had a local fab shop make me some aluminum spacers to raise my Crankenstein 3D up to meet the motor. Wasn't bad, they just charged $50 for the two and had enough material left over to make a short set for under the table to stabilize the mill a bit better than just washers.

- had a local fab shop make me some aluminum spacers to raise my Crankenstein 3D up to meet the motor. Wasn't bad, they just charged $50 for the two and had enough material left over to make a short set for under the table to stabilize the mill a bit better than just washers.

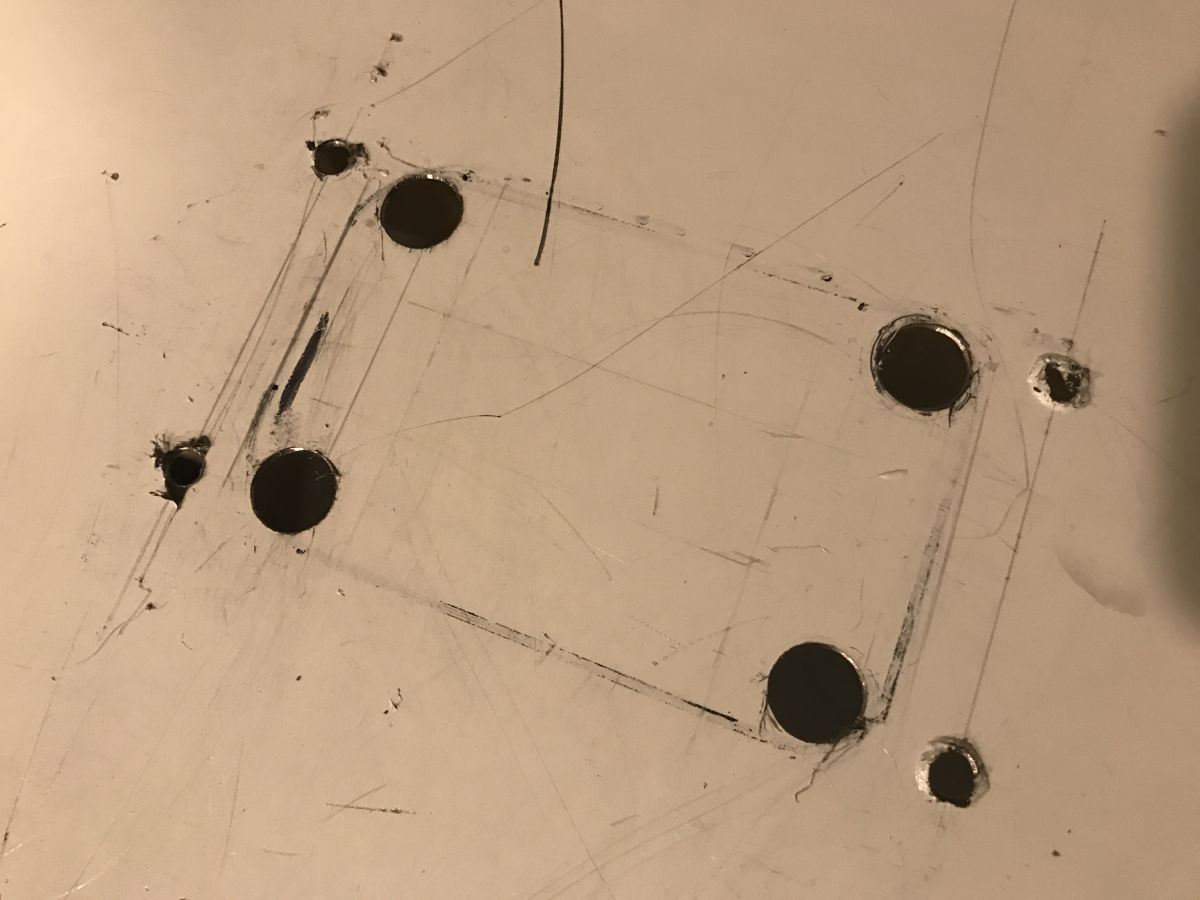

Well I finally finished my mill. Totally stole the spacer idea from hbt user dcpcooks- had a local fab shop make me some aluminum spacers to raise my Crankenstein 3D up to meet the motor. Wasn't bad, they just charged $50 for the two and had enough material left over to make a short set for under the table to stabilize the mill a bit better than just washers.

Pretty happy with how it turned out.

Well played sir, Well played! Everyone that comes over stares at the rollers through the plastic while its munching grain.

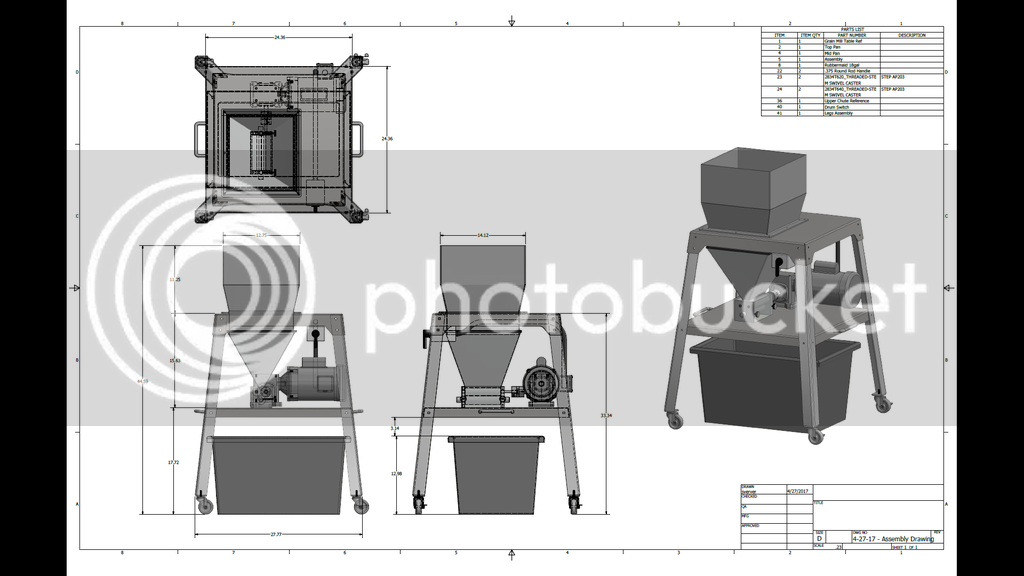

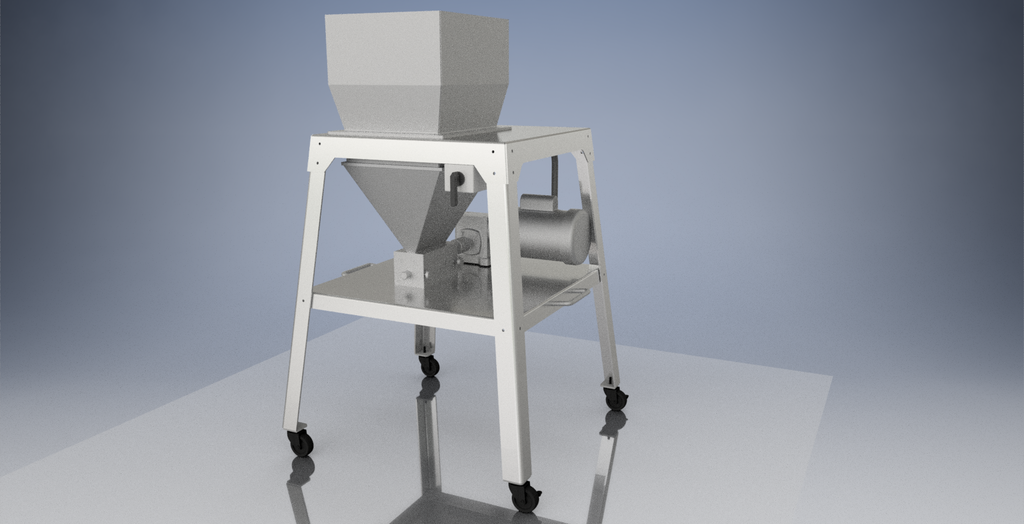

Sure, I used what I had on hand. If i bought a motor and gear box it would have been around the same torque but with a higher RPM. 58RPM will get the job done but a little slow. What information you looking for?Quote: A friend and I just finished our grain mill. Here are the specs

-Kegco 3 roller 11lb Hopper

-19lb Aluminum hopper extension for a 30lb capacity

-All aluminum frame

-1/4HP Motor 1725RPM

-30:1 Gearbox

-235in lbs output torque at 58RPM

-FWD/Reverse drum switch

Awesome job. If you don't mind, can you share the particulars of the motor and gear box?

What motor and gear-box did you use?

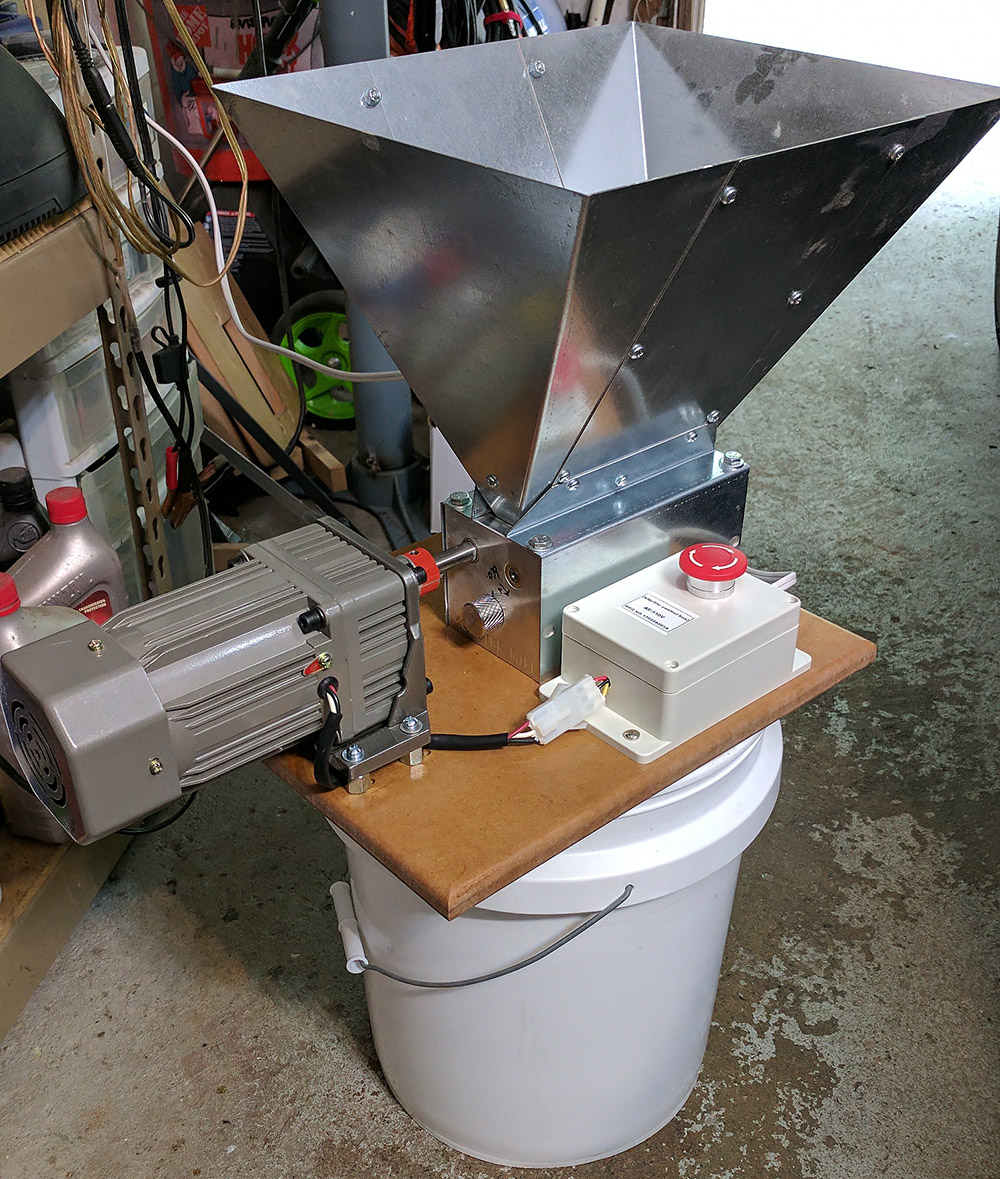

Finally got around to getting my mill motorized.

I'm tight for space, so a mill 'station' was pretty much out of the question. I wanted something bucket-top.

Motor is the Williams Brewing 3 roller motor.