biertourist

Well-Known Member

Here's a placeholder photo for mine, until I get it fully finished:

https://www.facebook.com/photo.php?fbid=10154065719976929&l=d893707f92

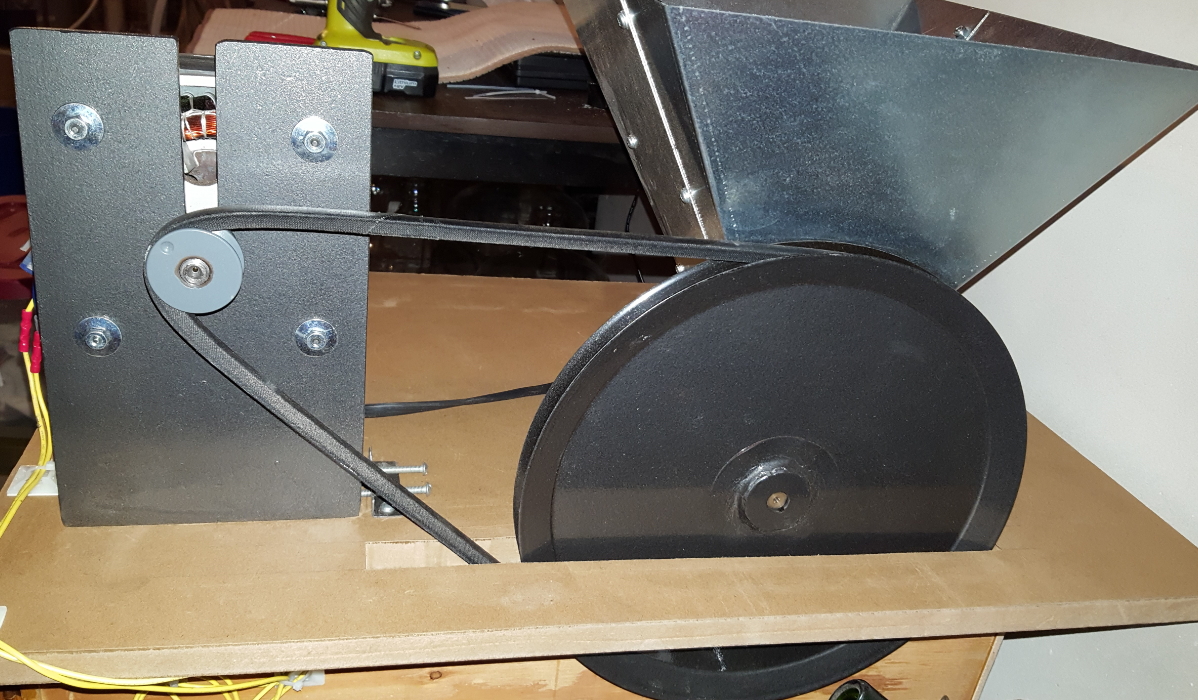

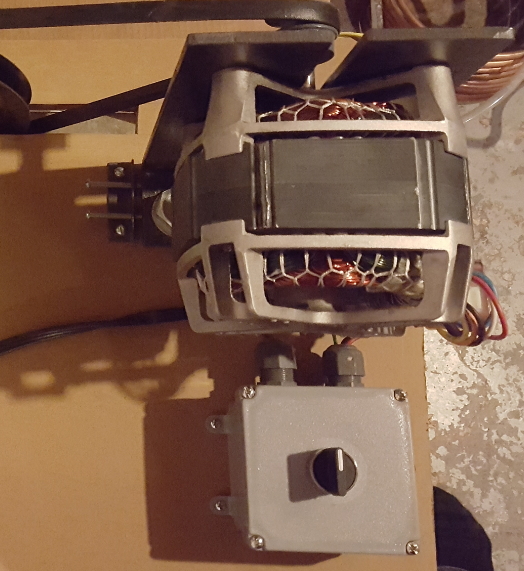

It's an Ikea Stenstorp kitchen cart I bought off of CraigsList ($100) and hacked by removing the middle shelf and front-bar, cut a hole in the butcherblock top, repainted it flat black with a rattle can as it had quite a few scuffs, and then added my existing Monster Mill MM2.0 with hopper extension and American Ale Works PowerGrinder. A buddy built the collar because I don't have the tools nor the skills.

I finished wiring up a forward and reversible drum switch last weekend but still have my special solution for avoiding dust that I need to add and document.

I'll come back to this post when I'm done and update it with the final photos and descriptions.

Adam

https://www.facebook.com/photo.php?fbid=10154065719976929&l=d893707f92

It's an Ikea Stenstorp kitchen cart I bought off of CraigsList ($100) and hacked by removing the middle shelf and front-bar, cut a hole in the butcherblock top, repainted it flat black with a rattle can as it had quite a few scuffs, and then added my existing Monster Mill MM2.0 with hopper extension and American Ale Works PowerGrinder. A buddy built the collar because I don't have the tools nor the skills.

I finished wiring up a forward and reversible drum switch last weekend but still have my special solution for avoiding dust that I need to add and document.

I'll come back to this post when I'm done and update it with the final photos and descriptions.

Adam

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)