Huaco

Well-Known Member

What's your crush look like? I've heard of a lot of guys running a.045 gap and getting really great efficiency.

What's your crush look like? I've heard of a lot of guys running a.045 gap and getting really great efficiency.

There's no standard roller knurling.

One mill's ".039" may be another mill's ".46", etc, when the crush is examined...

Cheers!

Here's an easy way to improve the crush quality:

http://braukaiser.com/wiki/index.php?title=Malt_Conditioning

If your shop teacher could see you now!!

TD

The e-stop works, but it's more cosmetic than anything else. But it could be a good thing. If both my hands are being sucked into the mill, I can hit the e-stop with my knee. :cross:

+ 1 on shimming the mill. You can see post #462 of this thread and see how kiblerjd shimmed his mill. Hope this helps, CastermmtThe chuck of the drill when tightened will align the shaft of the mill perfectly with the drill. Are you really need to do the is shim the mill or drill to the point where everything is nice and level when you secure the mill/drill to the table. Those drills have enough torque to bend that mill shaft in a heartbeat. I'm begging you not to run that thing like that. Where are you located?

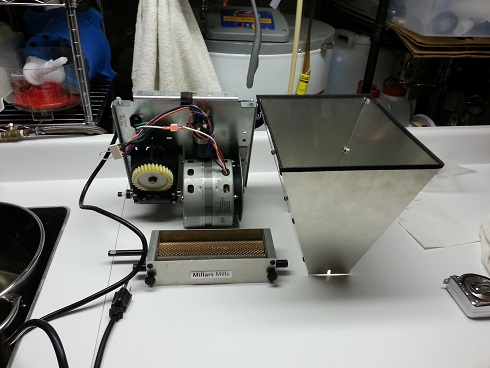

I bought a motorized crankenstien 3d grain mill set-up which utilizes a 10:1 pulley set-up. I want to switch it over to a worm drive gear reducer and I am not sure which gear drive reducer I would want.

The motor is a Worldwide Electric GP Motor T12-18-56CB

1/2 HP

1800 RPM

115/208-230V

56C Frame

Without Overload

Would this gear reducer be sufficent? The Motor has a 5/8th shaft but the mill has a 1/2 shaft.

http://www.ebay.com/itm/HUB-CITY-10-1-GEAR-REDUCER-MODEL-214-0220-61220-214-STYLE-C-5-8-IN-7-8-OUT-/171251635345?pt=LH_DefaultDomain_0&hash=item27df649491#ht_994wt_1106

Thanks in advance.