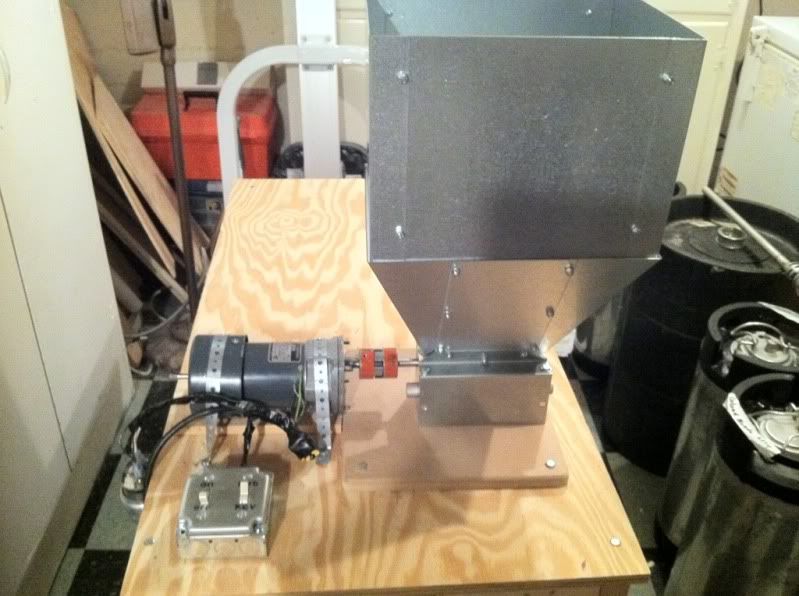

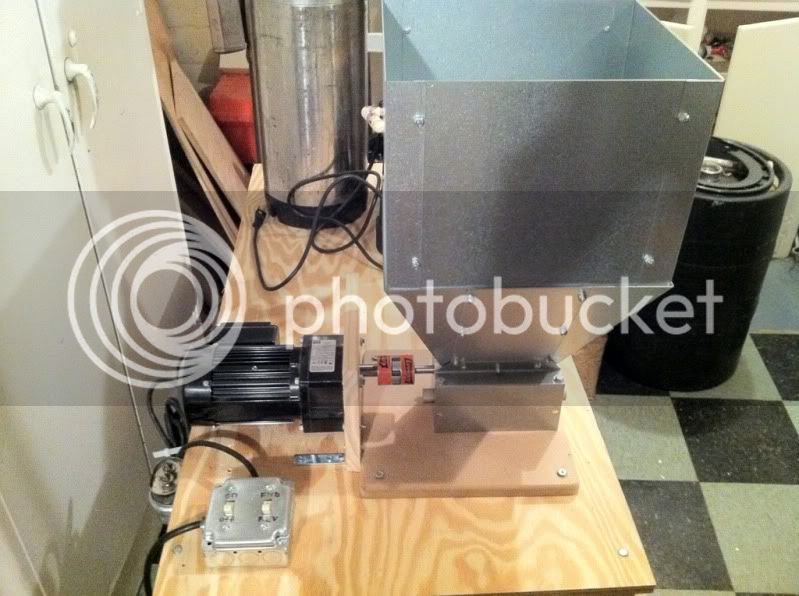

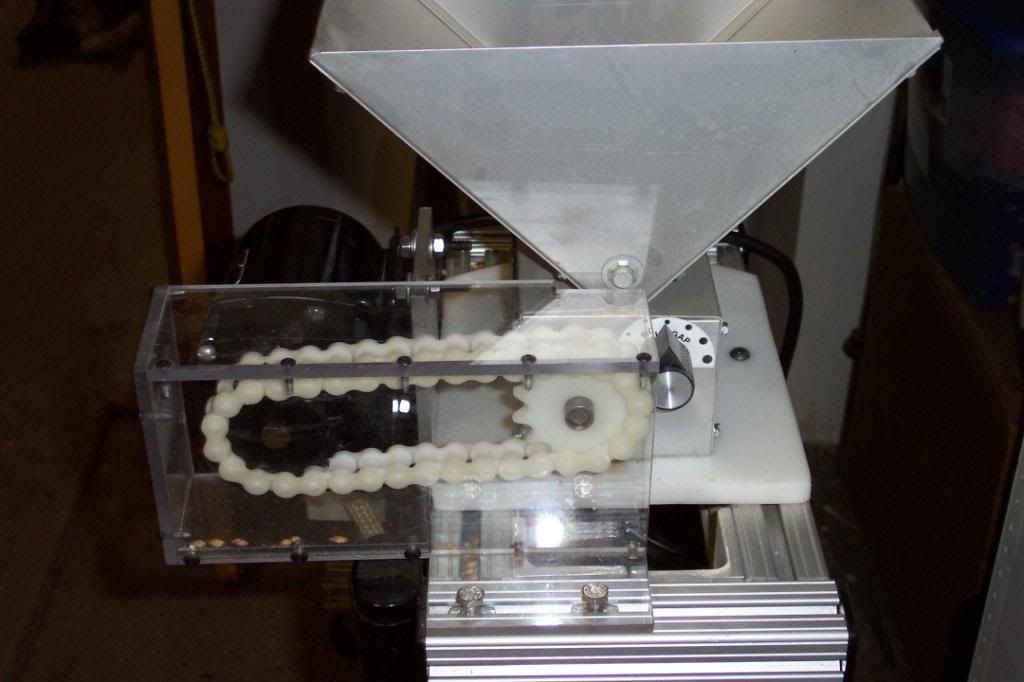

Here is picture taken during the build phase of the cobbled up malt mill hardware for the automated brewing system, hopper on right side, screw auger to gear motor driven valley mill on top, and 3" drop tube to mash tun https://picasaweb.google.com/kevin.ladue/ScrewConveyor#5188941488760211522

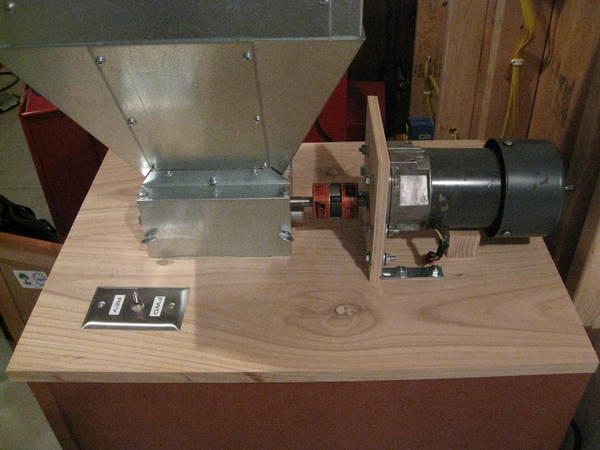

Here is a later picture of the system taken during testing https://picasaweb.google.com/kevin.ladue/Panels#5339967138764297570, insulation and tubing covering are not finished

Seriously. Dude. AWESOME! Very, very well done.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)