pola0502ds

Well-Known Member

- Joined

- Jan 12, 2011

- Messages

- 846

- Reaction score

- 3

Thanks buddy, I will have to check when i get home which motor I have. I know is has 40 in/lbs of torque and the motor is running CCW.

Which direction are you running the motor when milling CCW or CW?

Reason I'm asking is the Gear Motor 5-1098 is designed to run CCW (viewed from the wiring end). If run CW it has far less torque available.

And another thought. If you got this Gear Motor 5-1074 it has far less torque available in either direction as well as a much lower speed.

P-J

I know you solved your issue with a stronger motor but, yes, one would need to flip the rollers and then the mill so that the rotation is correct.Hmmmm... Given the way my mill works I need a motor that turns the mill clockwise. Did you flip the internal rollers on your mill?

When I used this motor, it did jam a lot. It really is a torque issue, although I ran mine spinning clockwise when looking from the back of the motor and CCW when looking from the front.

That was the only way to do it unless you flip the rollers in your mill or something, no?

Which direction are you running the motor when milling CCW or CW?

Reason I'm asking is the Gear Motor 5-1098 is designed to run CCW (viewed from the wiring end). If run CW it has far less torque available.

And another thought. If you got this Gear Motor 5-1074 it has far less torque available in either direction as well as a much lower speed.

P-J

Hmmmm... Given the way my mill works I need a motor that turns the mill clockwise. Did you flip the internal rollers on your mill?

When I used this motor, it did jam a lot. It really is a torque issue, although I ran mine spinning clockwise when looking from the back of the motor and CCW when looking from the front.

That was the only way to do it unless you flip the rollers in your mill or something, no?

Here is a picture of my mill.

Take a look a the picture, I have a lot of you have the same motor and I have a question.

Have you add any problems with the motor jambing because you have to much grain in the hopper. I do all the time. I wonder if I need to close up the exit portion of the hopper to limit how much grain hits the rollers at once.

I think that your hopper design might be part of the cause of your jamming problem. A narrow, tall hopper puts more weight of grain on the rollers to begin with. A tapered hopper wider and longer would put more of the weight on the hopper itself.

I'm using that motor with a three roller Crankandstein and am using a 5 gal. water jug as a hopper. I have a plate on top of the mill with a 3/8" by 4 1/2" slot directly above the roller gap. Above that is a block of wood bored out to fit the neck of the water jug. The first trials with 14 lbs. of grain had no problems that weren't operator caused. The weight of the grain was spread out over the entire surface of the jug, not just over the rollers.

fwiw, it takes about ten minutes to convert a Barley Crusher from CW to CCW rotation of the driving roller. Here's a quicky "How To":

Remove the two screws and nuts holding the hopper and remove it. Unbolt the mill it from the base, unscrew and remove the front/back plates, wiggle the end plates apart, take the driving roller out, and flip it end-for-end before reinserting it into the end plates.

Reattach the front/back plates (but leave the screws a bit loose) and place the mill right-side-up with the handle shaft on the same side of the base as before (so the front is now the back, etc). Reattach the base (again, leave the bolts a bit loose), then attach the handle crank. Rotate the crank slowly, looking for any "hitching" that would indicate misaligned bearings, then press down on all four plates so they are flat to the base, and start snugging up the screws for the front/back plates and the two mounting bolts until they're all tight and the crank moves freely. If the crank develops a "hitch", loosen everything up and try again.

Thanks, P-J, for the information on the (very popular) 5-1098 gear motor. I was about to design my grinding station/cabinet so your post was very timely! While many have had no problems running it in reverse (CW) with Barley Crushers, I prefer optimal operation over just being lucky

Cheers!

What about this motor for a mill?

I guess it does require a start relay that is not included and has that open fan at the back. 60 in/lbs is probably solid on torque and it runs CW. Price is right!

HERE'S ANOTHER good motor and a nice price.

Although you'd have to buy the capacitor separately. Still...

My mill is built, but I'm still looking at motors on ebay. WTF?

Although it has 20 in/lbs, it runs at a very slow speed. Not to sure I would consider that..

This motor is way better then the other one I just commented on. It has a shlt load more torque but it still runs at a slower speed. If I am not mistaken, with RPMS there is a certain point where if it is running too slow it stops working well? I would choose this one over the other one. Looks like this motor runs at 80 RPM.

HERE'S ANOTHER good motor and a nice price.

Although you'd have to buy the capacitor separately. Still...

My mill is built, but I'm still looking at motors on ebay. WTF?

HERE'S ANOTHER good motor and a nice price.

Although you'd have to buy the capacitor separately. Still...

My mill is built, but I'm still looking at motors on ebay. WTF?

If I am not mistaken, with RPMS there is a certain point where if it is running too slow it stops working well? I would choose this one over the other one. Looks like this motor runs at 80 RPM.

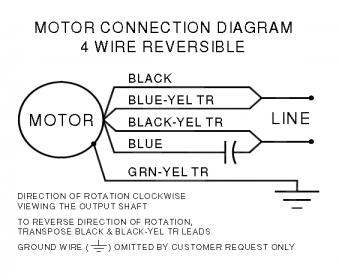

Can anyone tell me how to wire this? I would like to have a single switch with Fwd/Off/Rev.

Thanks for the pointer. I received mine yesterday. I offered 75.00 and it was accepted. Fast shipper. Now I need to get the capacitor and coupler.

Looks like he still has 3 available.

Yeah Dgonza9, I have ordered the coupler and capacitor. I'll order a switch tomorrow and hopefully ready to test it out this week. This motor is a beast of a thing. I'm sure it will do all I ask of it. Last I looked there were 2 left.

I have been looking for a deal on a motor for some time. I almost went with the Surplus Center 177 rpm motor. But knew that it would be marginal with my 3 roller. So far I'm glad I waited. We'll know soon.

Thanks,

Ron

Got her up and running yet?

Im not totally happy with mine (jams ALL THE TIME !) but its a moster mill MM3. check it out here http://hollisbrewco.blogspot.com/2011/09/brewery-tour.html