You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MN Kegerator Build Log

- Thread starter kMc21

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

collinsDPT

Well-Known Member

That is completely badass. Thanks for the updates!!

- Joined

- Mar 21, 2013

- Messages

- 25

- Reaction score

- 0

Awesome work! Looks like it is going to turn out awesome. I especially like the custom paint job!

My only thought was that with tall tap handles you may have an issue with opening the freezer door....but that is manageable.

Great work! Say hello next time you make it down to Midwest. We recently converted a stand-up freezer into a keezer for the back office, but nowhere near as decked out as yours.

My only thought was that with tall tap handles you may have an issue with opening the freezer door....but that is manageable.

Great work! Say hello next time you make it down to Midwest. We recently converted a stand-up freezer into a keezer for the back office, but nowhere near as decked out as yours.

Operational!

After crossing my fingers, the old fridge made it down to an icy cold temperature- taking almost an entire 24 hrs to get there! I hacked together a line with some misc fittings and have my first beer on tap!

Still to do: Arrange gas manifold, lines, and fittings so I can have more than 1 beer on;

Make and mount carbon drip tray surround;

Finish trim around ss backsplash (as soon as the damn hardware store gets more in stock)

Brew more beer! (tap #2 is bubbling away right now in primary)

After crossing my fingers, the old fridge made it down to an icy cold temperature- taking almost an entire 24 hrs to get there! I hacked together a line with some misc fittings and have my first beer on tap!

Still to do: Arrange gas manifold, lines, and fittings so I can have more than 1 beer on;

Make and mount carbon drip tray surround;

Finish trim around ss backsplash (as soon as the damn hardware store gets more in stock)

Brew more beer! (tap #2 is bubbling away right now in primary)

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

Thanks, bmeulebroeck! I'll be after some lines and flare fittings soon!

I thought about the handles, and without pinning the doors together I'll just stick with the shorties- The freezer will be used for cold food storage.

[ame]http://youtu.be/XPWiuk0nKw4[/ame]

My hacked-together beer line ended up around 14 feet with 2 different diameters and a bunch of odd fittings. It's a slow pour, but that's at around 9psi and can be balanced later.

You know it's cold when the faucet condenses on the first pour!

I thought about the handles, and without pinning the doors together I'll just stick with the shorties- The freezer will be used for cold food storage.

[ame]http://youtu.be/XPWiuk0nKw4[/ame]

My hacked-together beer line ended up around 14 feet with 2 different diameters and a bunch of odd fittings. It's a slow pour, but that's at around 9psi and can be balanced later.

You know it's cold when the faucet condenses on the first pour!

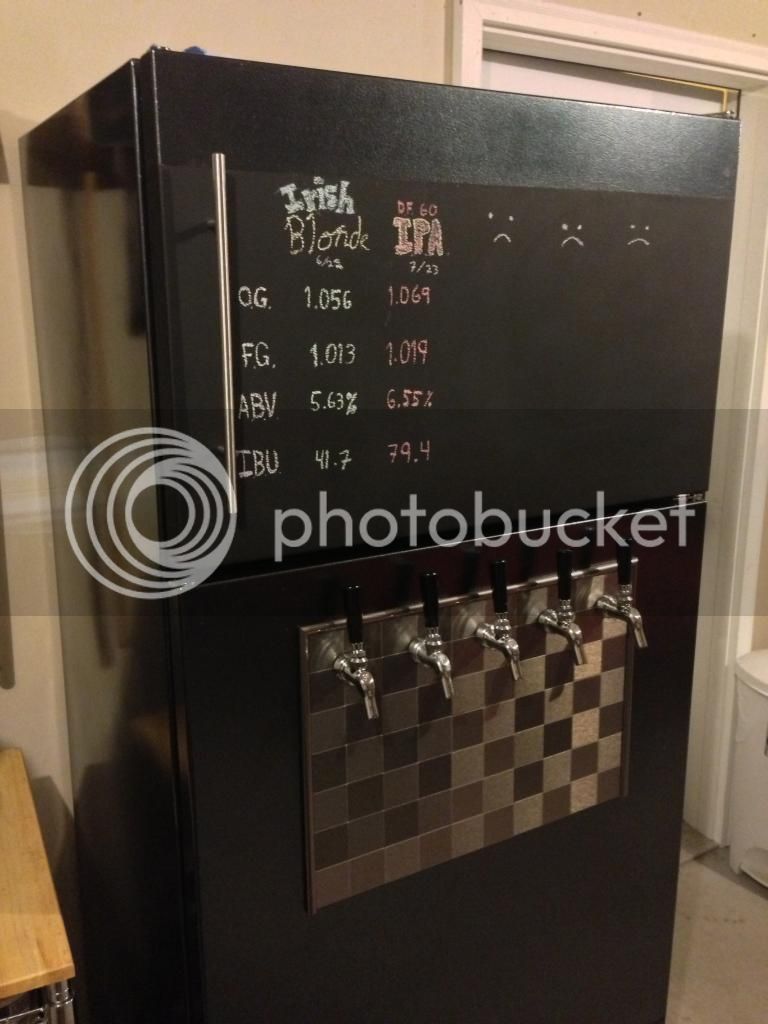

No time to get a lot of work done. The update is that the hardware store finally got more trim pieces in stock, so I was able to trim out the backsplash tile.

The IPA is a dogfish clone, and the first time I'm attempting a dryhop in a keg. I have a stainless dip tube filter, and just tossed 2 oz of hops right in before racking from primary. I hope it doesn't clog!

The drip tray project is still waiting for me. Summertime is proving to be too much fun with weekend camping trips and family vacations keeping me from being bored enough to play with epoxy in the garage. I plan to mold the tray surround from MDF or ply and skin it with some carbon fiber left over from a separate project. I'll mount it to the fridge door with 6" steel 'L' brackets. Instead of conventionally fitting it to the outside of the door, I'll mount the bracket through the door so it is attached to the inside where it won't be seen. Some measurements are all the progress I've made thus far- it just needs a few hours of solid work.

The IPA is a dogfish clone, and the first time I'm attempting a dryhop in a keg. I have a stainless dip tube filter, and just tossed 2 oz of hops right in before racking from primary. I hope it doesn't clog!

The drip tray project is still waiting for me. Summertime is proving to be too much fun with weekend camping trips and family vacations keeping me from being bored enough to play with epoxy in the garage. I plan to mold the tray surround from MDF or ply and skin it with some carbon fiber left over from a separate project. I'll mount it to the fridge door with 6" steel 'L' brackets. Instead of conventionally fitting it to the outside of the door, I'll mount the bracket through the door so it is attached to the inside where it won't be seen. Some measurements are all the progress I've made thus far- it just needs a few hours of solid work.

ja09

Well-Known Member

Care to share which big-box store it was?I found a great backsplash product at a local big-box home store.

Care to share which big-box store it was?

Menards. Love that place.

user 78027

Well-Known Member

- Joined

- Apr 15, 2011

- Messages

- 274

- Reaction score

- 13

Totally Awesome, I am currently handicapped and can't build my keezer I was given for my last birthday, My SWMBO also can't stand all the bottles laying around  .

.

I really like the tiled look and the drip tray. You would never know it is an 80's refrigerator.

Inspirational for sure.

I really like the tiled look and the drip tray. You would never know it is an 80's refrigerator.

Inspirational for sure.

fifthcircle

Well-Known Member

Love that CF drip tray!

Where do you buy your CF supplies?

Where do you buy your CF supplies?

ja09

Well-Known Member

Do you know what your casters are rated for? I was looking at some with a 300lb rating that look similar to yours, but didn't think that's enough with a few full kegs.

Casters are rated at 175# each. The fridge rolls fine with 4 filled kegs, a bunch of bottles, and a freezer of food. I have no idea if they'll hold up over time. I had considered using all-steel shop casters, but just went with rubber ones instead. I know you don't want to operate them at their rated capacity, but i figured it would be difficult to ever get close to more than 700lbs!

The carbon is 6 oz 2x2 twill that I bought in a bulk roll on eBay. 6 oz is light enough to drape well into curves, though you need a few layers to give a uniform coverage without bleed- through of whatever's underneath. The twill weave is what gives it the distinctive diagonal zig-zag pattern.

I used system three silvertip epoxy resin that I bought in person from their composites distributor warehouse when I lived in Seattle. It sets up completely clear and is easy to mix by weight.

I used system three silvertip epoxy resin that I bought in person from their composites distributor warehouse when I lived in Seattle. It sets up completely clear and is easy to mix by weight.

Long time to leave this thread, but I realized that I had finished the build and not posted photos.

-Made an aluminum bracket to mount CO2 bottle to the side.

-Ran a second regulated gas line to have charged water or soda at a higher PSI.

-Split the Primary gas line with a wye fitting at the regulator so I have an accessory gas port on the outside for purging kegs/fermentors/etc. Very handy.

-Added a Sankey tap on MFL fittings so I can swap in commercial kegs during the winter brewing hiatus.

-Made all beer lines minimum 10' of 1/4" tubing. The cheap vinyl stuff.

-Made an aluminum bracket to mount CO2 bottle to the side.

-Ran a second regulated gas line to have charged water or soda at a higher PSI.

-Split the Primary gas line with a wye fitting at the regulator so I have an accessory gas port on the outside for purging kegs/fermentors/etc. Very handy.

-Added a Sankey tap on MFL fittings so I can swap in commercial kegs during the winter brewing hiatus.

-Made all beer lines minimum 10' of 1/4" tubing. The cheap vinyl stuff.

As it sits today in the garage:

(purchased the black butte, but brewed the others)

I can officially call it 'finished' though I do have an idea floating around for some sort of security/safety control. The kids are going to get tall enough to reach the handles in a couple years, and then in a few more years old enough to realize what beer is. I still want the ease of pulling a pint without unlocking anything, though. The current thought involves actuated ball valves on the beer lines inside the door, with an arduino and fingerprint reader. I've never seen anyone attempt it that way before, but I have a fingerprint gun safe that is fast and amazing, and It would be cool to have the same functionality on the kegerator. Still haven't worked out the details, but someday.

(purchased the black butte, but brewed the others)

I can officially call it 'finished' though I do have an idea floating around for some sort of security/safety control. The kids are going to get tall enough to reach the handles in a couple years, and then in a few more years old enough to realize what beer is. I still want the ease of pulling a pint without unlocking anything, though. The current thought involves actuated ball valves on the beer lines inside the door, with an arduino and fingerprint reader. I've never seen anyone attempt it that way before, but I have a fingerprint gun safe that is fast and amazing, and It would be cool to have the same functionality on the kegerator. Still haven't worked out the details, but someday.

-Added a Sankey tap on MFL fittings so I can swap in commercial kegs during the winter brewing hiatus.

I just finished my electric BIAB build. So, if you ever want to brew in the winter just shoot me a line. I brew in my garage with my current setup. It's heated any all that...so it's very comfortable in the winter.

Really like the kegerator. Looks really good. I just finished my Keezer build a few weeks ago. But haven't had time to fill it with beer yet. Hope to change that this week.

Similar threads

- Replies

- 0

- Views

- 780

- Replies

- 8

- Views

- 4K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)